Evening all

I'm building up a new engine and I'm at the point of buying a flywheel package. MED say in there details that the flywheel, backplate, diaphragm and clutch package should be installed without dismantling to maintain the balance otherwise it will need to be re-balanced.

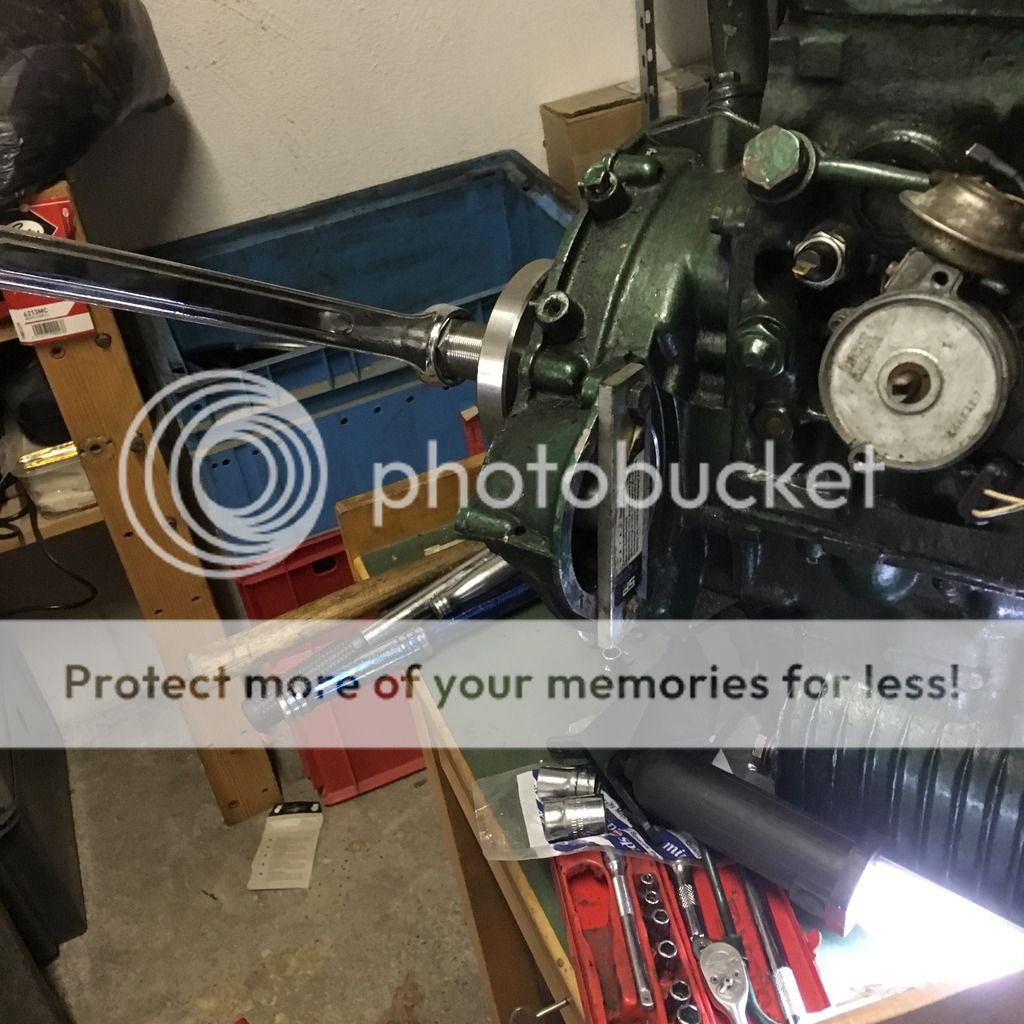

I've watched a video on youtube (can't remember the name of the guy) who was building a race engine. He didn't use a locktab and put the tool through the diaphragm to tighten. What are peoples thoughts on this as otherwise how can you install it all without taking it apart? I don't like the thought of a flywheel spinning by my feet with no locktab to be honest but is this what people do?

Secondly, I want to use the same flywheel etc on another engine I'm building after the summer. Again, how do I get it off without taking the diaphragm off to use a puller?

Cheers all