I am trying to source a pulley for me megajolt kit and have a question.

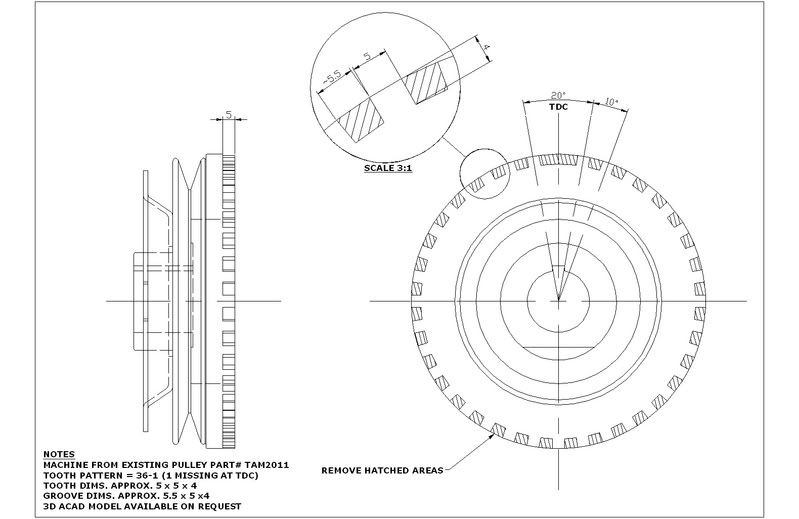

I can get my brand new crank pulley machined at a local machine shop (probably cheap, through work) but need to know where the missing tooth sits in relation to the woodruff key cut out on the pulley. Does anyone have a piccy of one that they could post up?

From what I have read I think the missing tooth needs to correspond with TDC, which means it would be inline with the woodruff key slot, no??? Then I mount the pickup 90 degrees before that?

One other thing, does the pulley need re-balancing once it's been machined?

I thank you please!