Just wondering if anyone has any thoughts on the lambda reading taken from my car this morning?

In the first video the car is idling. I took the video because after a 2 hour (100 mile) drive the revs rose, then dropped off and I struggled to keep the car going, it ran rough, seemed rich to an uneducated man like me.

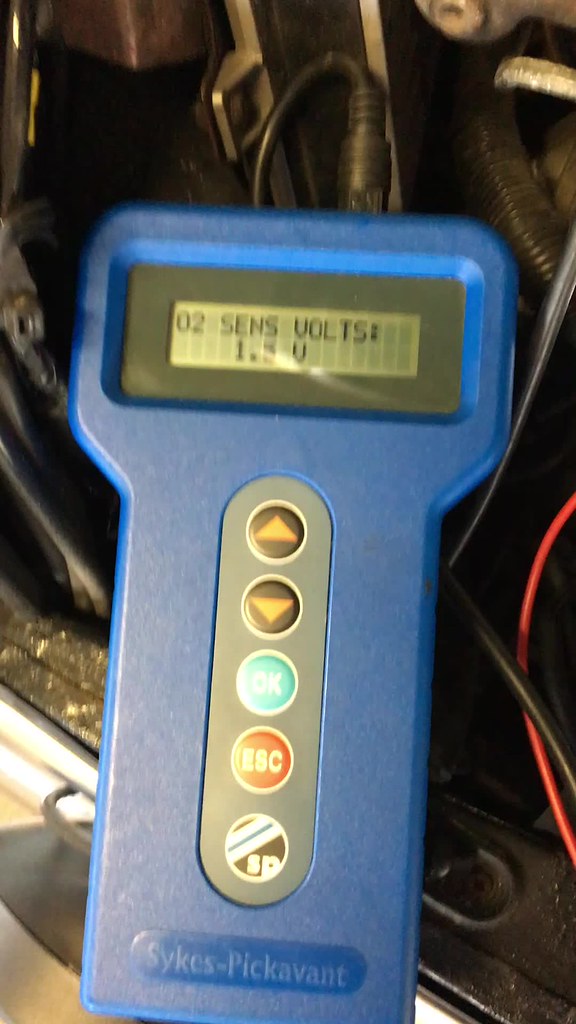

Diagnostic 1 - 09/07/18

Diagnostic 1 - 09/07/18

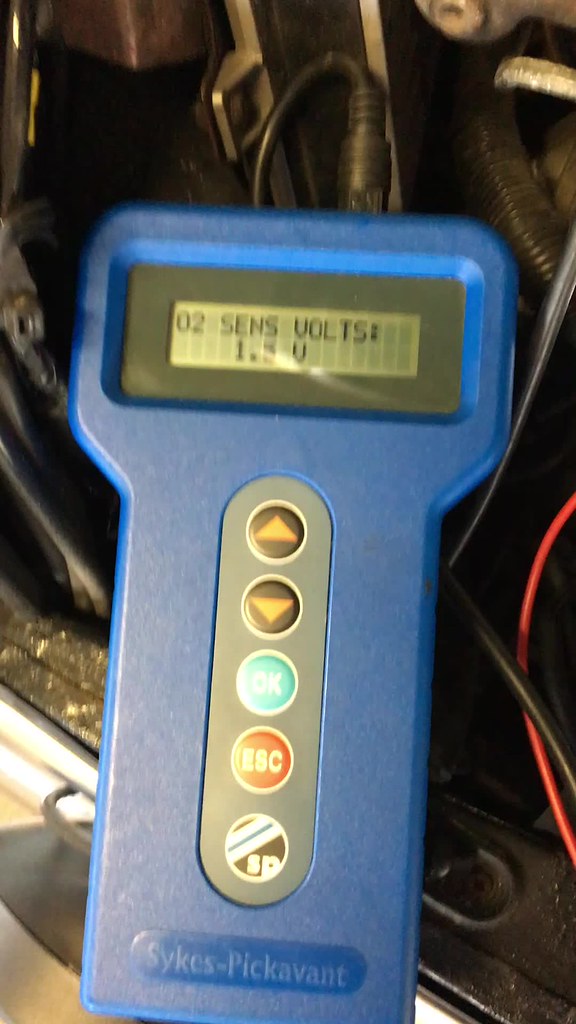

After that I took this one. It's me adjusting the engine speed using the throttlebody, not the car itself.

Diagnostic 2 09/07/18

Diagnostic 2 09/07/18

From what little I know, and I've read every thread I can find on the matter, this sensor seems to be sticking high, rather than fluctuating high/low. Is this the case, or will it stay high like this in certain circumstances?

If the sensor fails is there a default value the car will use? Thought I'd seen one somewhere.

Finally would the readings be like this if the wiring was knackered,as it was last time, or is this definitely a duff sensor?

I'd appreciate any help given.

Edited by humph, 09 July 2018 - 01:30 PM.