1964 Sunbeam Alpine Restoration

#16

Posted 16 March 2009 - 06:20 AM

panels that came were.. 2 outer rockers, 2 fender repair panels (section behind the front wheel), and the front valence... also got all the seals and rubber for the whole car but that wont be getting used for quite some time... once i get cracking i will update accordingly...

Al

#17

Posted 23 March 2009 - 07:47 PM

#18

Posted 23 March 2009 - 08:24 PM

Edited by Al*, 23 March 2009 - 08:28 PM.

#19

Posted 23 March 2009 - 08:28 PM

Al

#20

Posted 23 March 2009 - 08:41 PM

#21

Posted 23 March 2009 - 09:00 PM

#22

Posted 24 March 2009 - 04:02 PM

heres some of the panels we received yesterday anyways...

#23

Posted 24 March 2009 - 04:08 PM

#24

Posted 24 March 2009 - 07:23 PM

#25

Posted 17 December 2009 - 08:11 AM

So since being back have been doing the usual working on minis and such and have started cracking on with this.. there is loads of fabrication work to be done so it is slow going but my od man and me are out there every chance we get... have some pictures so I'm going to stop this boring typing and start putting up pictures....

to start with here is a comparative picture of the right front floor pan... this really shows how poor the panel purchased was.. not the right size, shape, floor ribs etc... basically useless... so the one on the left is the one my dad banged out a few days ago... still needs a bit of work but is a million times better than the one we bought...

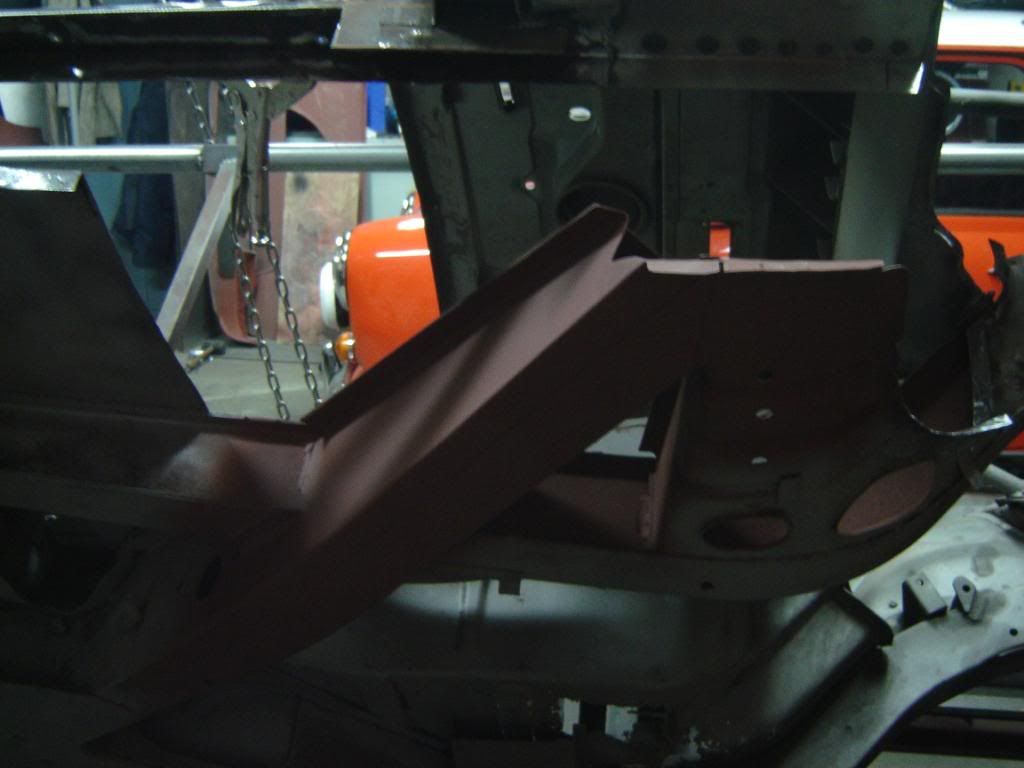

this is the frame crossmember bit that was totally rotted out....

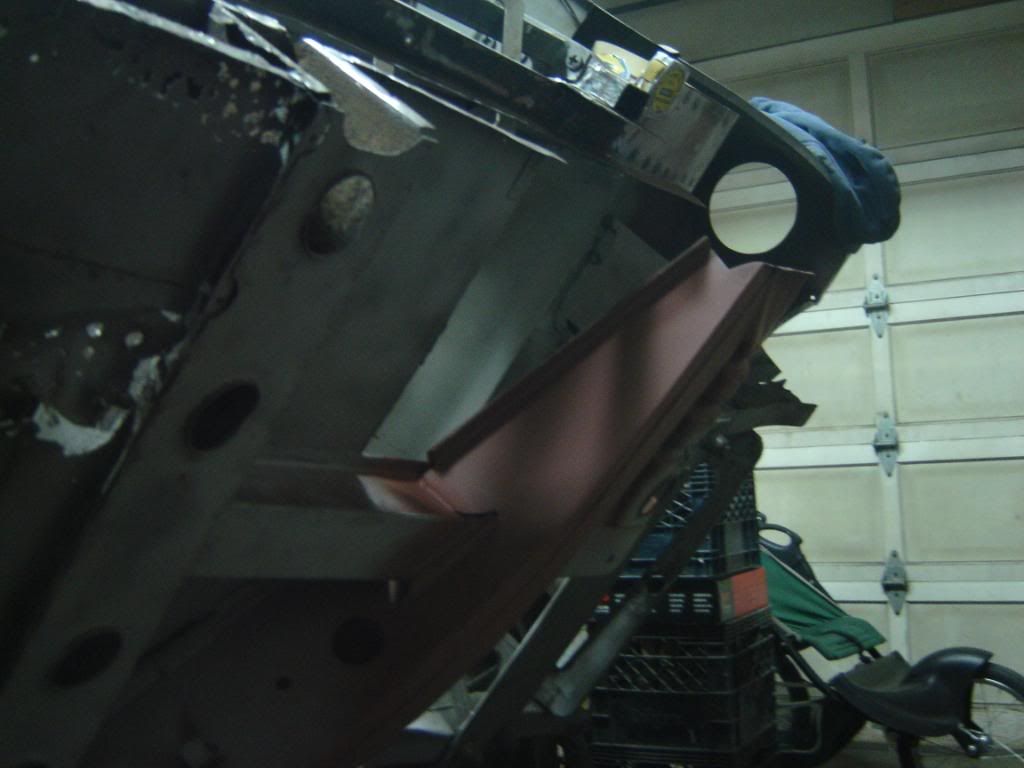

heres a picture of the area with it removed, a sleeve fitted to weld the new frame peice on and it all cleaned up and weld thru primered where necessary

couple comparrisons of the peice removed and the one I hand made out of 18 guage steel to replace it... was tricky to do as it was rusted out so far back there wasn't much to template off of....

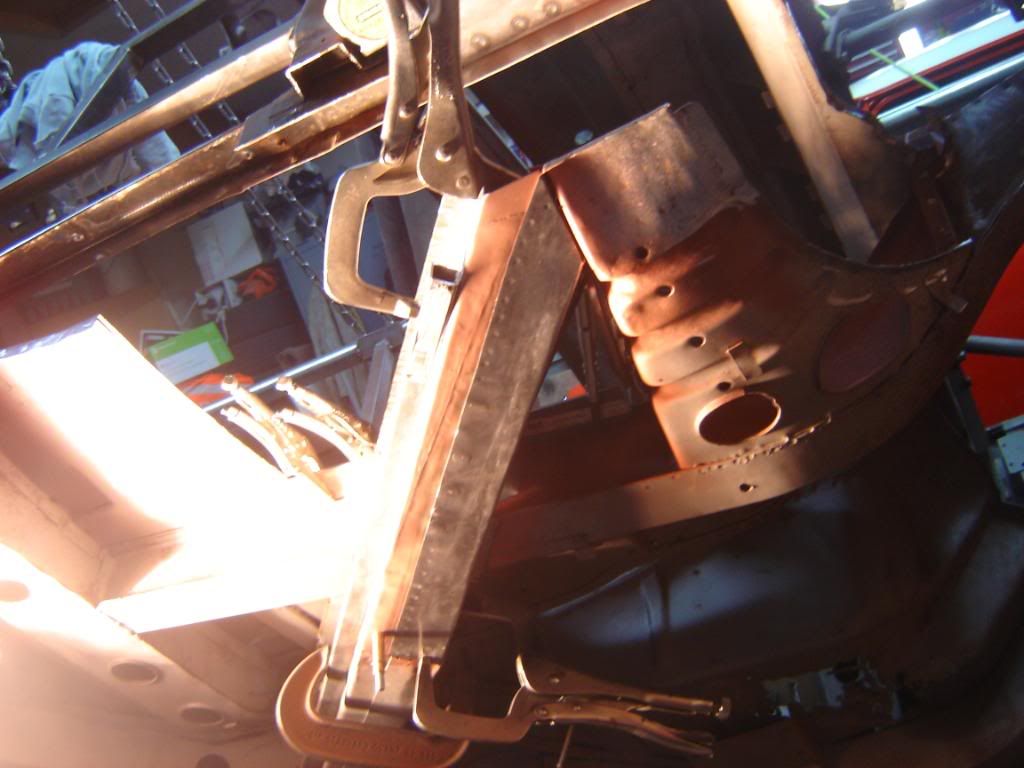

all clamped in place ready to start welding

all welded in ground down and red oxide primered....

#26

Posted 17 December 2009 - 08:23 AM

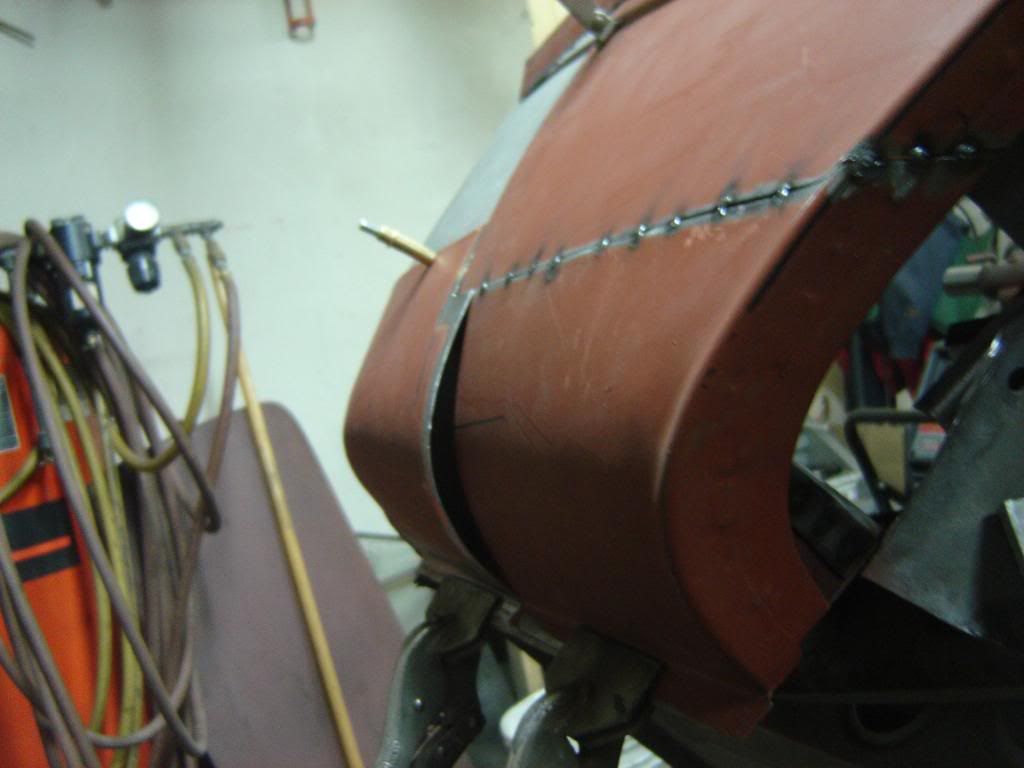

the quarter supplied was sent in the two peices shown.. fine enough.. but when the rear peice was put in place and then the front one as you can see the front peice (main bit of the quarter) was 1.5 inches to long....

so i marked it out and sliced 1.5 inches out of the quarter to bring it up to where it would need to be....

and tacked that bit back in place....

as you can see when i sectioned it it made it so the curve at the bottom of the two peices didnt match....

so i had to slice them both and section in a triangular peice to get the curves to meet up.... it has since all been tacked and is no longer held in with masking tape... but i dont have a picture of it... the result is quite good and the quarter fits the way it should...

i will take more pictures of this as i go... the reason i had to jump ahead and get the quarter fitting is that the inner wheel well is all rotted out (so badly there was nothing to really get a good template off of so i had to get the quarter panel in place to be able to strart making the panels that go in behind it... there are similar fitting issues with the lower front wing section as well and similar procedures will have to be done...

we have made the peices to go in the inner wheel well behind the quarter... i think there is a total of 4 peices that we made to go in behind there... theres also that bit of frame you can see in behind the pictures of the bottom of the quarter .... it took 4 or 5 peices to bet that back to the way it should be.... and while i was at the back doing this my dad had his head shoved up in the wing cutting out rust and welding in peices he made... he had to cut the inner wheel well in half to gain access to the rot in behind it and it will be getting refitted...

we have done loads of little bits and peices as well but have not been too dilligent in our photgraphing...sorry... now that i am reviving this thread i will take more pictures as we go and make posts as we progress.... hope you enjoy reading as much as i do doing the work...

Edited by Al*, 17 December 2009 - 08:28 AM.

#27

Posted 17 December 2009 - 08:36 AM

#28

Posted 17 December 2009 - 09:05 AM

looking back I think its also worth a mention that that twisted lower rad support has also since been straightened out and welded up, the right headlight area has been rebuilt, a couiple small peices have been patched around the headlight itself on the right wing and there are deffinitely things I'm forgetting....haha

Al is there any room in that garage with your Mini's

#29

Posted 17 December 2009 - 05:54 PM

anyways i'm going out to the garage to make some more headway on this...

#30

Posted 17 December 2009 - 10:09 PM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users