Mine went thrue its M.O.T like this sills spot welded on then seam sealed and waxoiled M.O.T tester said nothing so i would think your be ok.Hi

i am currently restoring my 1960 mini minor. The new floor panels and outer sills on these are one part, and i am currently just doing the Right hand side.

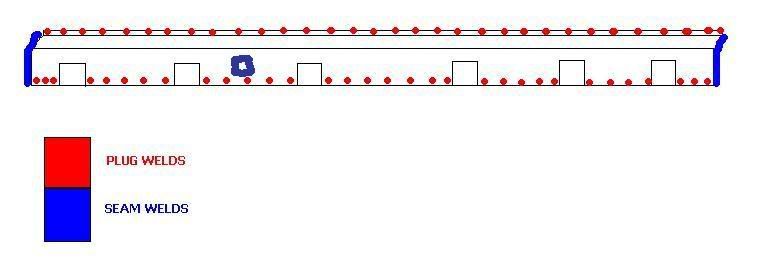

Anyway, on the original car, it looks like the sill and door step were roller welded together, the spotwelds being 5 or 6 mm aprt from eachother.

I have plug welded the new panels together (with my MIG welder) at approximately 20mm apart between the welds. However, my plug welds are bigger in diameter then the original spotwelds.

Is this OK for an MOT, or do i need to carry out more welding?

Thanks

John

Welding Sills (mot Advice)

#16

Posted 02 February 2009 - 01:05 AM

#17

Posted 02 February 2009 - 07:52 PM

Replacement panels welded as originals

Patches or repair panel seam welded

That is until another mot man said to me the other week seam weld everthing, so i was going to ask if it had changed recently?

But youve all answered this for me.

Some years ago i did have mot man ask to see welds after it had been painted-so i now take pictures.(probably wanted to know what a good weld should look like)

Cheers.

#18

Posted 02 February 2009 - 08:42 PM

#19

Posted 02 February 2009 - 08:49 PM

#20

Posted 02 February 2009 - 09:51 PM

I restore cars and if i were to leave all my repair welds there or seam weld everything i wouldn't be in a job for long. and the car would way twice what it should lol

Hi

So, do you mean you leave your sills spotted? My prep work, including zinc coating the surfaces to be welded is thourough. I have done a neat job, but I just want to be sure this type of welding is enough.

Cheers

#21

Posted 02 February 2009 - 10:10 PM

#22

Posted 02 February 2009 - 10:38 PM

#23

Posted 02 February 2009 - 10:42 PM

#24

Posted 02 February 2009 - 11:16 PM

a bit ambigious pete, because a panel was spot welded at the factory does not mean a replacement panel has to be spot or plug welded you can still seam weld, there is a lenght and spacing for seam welds i believe for mot standard. it does not have to be continious.

Yes I didn't mean it was the only way, just that if you want to pass an MOT, if it is done to the same standard, it will be fine.

#25

Posted 03 February 2009 - 07:50 AM

Thinking back i remember operators in the factories having sheets with basic instructions??

Just make life easier for dismantle and assembly??

Cheers.

#26

Posted 03 February 2009 - 09:04 AM

http://www.theminifo...showtopic=38927

Edited by black jack1275, 03 February 2009 - 09:05 AM.

#27

Posted 03 February 2009 - 11:14 AM

i am still confused with some people saying the sill flange to door step is not roller welded, all minis up to 1996 that i have replaced the original sills have been roller welded.

because of the roller welds i alway cut under the seam and leave the flange on and seam weld the sill to the 2 flanges (the door step with the old sill flange still on).

#28

Posted 03 February 2009 - 01:24 PM

The seams down the A pillars and C pillars are also continuously welded.I can not say for the early minis but all i have worked on have has spaced spot welds. And as previously stated the continuous spot welds were only to seal IE tanks and roof panel withing gutter.

#29

Posted 03 February 2009 - 07:20 PM

The seams down the A pillars and C pillars are also continuously welded.I can not say for the early minis but all i have worked on have has spaced spot welds. And as previously stated the continuous spot welds were only to seal IE tanks and roof panel withing gutter.

I did not say they were the only places. as stated it does not aid the strength excessively it is usually to seal!

And all my minis have been pre 1996 and none that i have replaced the sills on have been fully/roller welded some have had closer spaced spotwelds and even have differed side to side but not roller welded. And yes i mean replacing the original sill not one someone else has fitted.

Interesting as it is the topic is going a little of. As peter and others have stated spaced spot welds/plug welds are sufficient and well to mot standard.

Edited by In-a-mini, 03 February 2009 - 07:20 PM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users