Time for an update people, as any of you know who work nights it buggers you up for at least 2 days after them. Well ive got 3 weeks worth! The money will be nice but im not getting a lot done on mini! L

So ive basically been doing little things

Fitted some mesh behind the grill holes

20180207_115748 by Lawrence Balls, on Flickr

20180207_115748 by Lawrence Balls, on Flickr

20180207_125234 by Lawrence Balls, on Flickr

20180207_125234 by Lawrence Balls, on Flickr

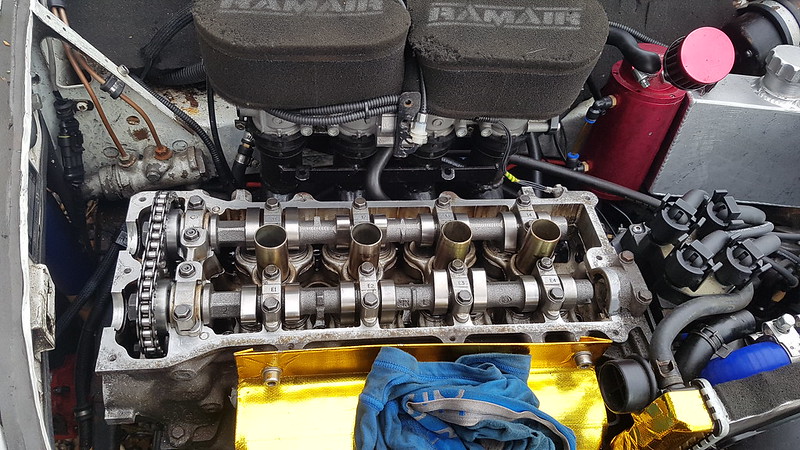

fitted heat reflective tape, some heatwrap to the exhaust

20180207_123142 by Lawrence Balls, on Flickr

20180207_123142 by Lawrence Balls, on Flickr

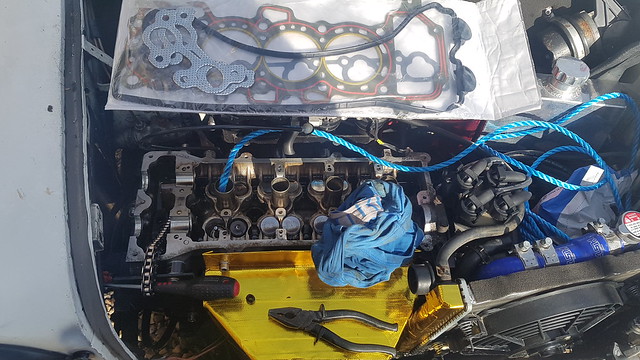

Engine bay now completely done. You can see the new place for my coil pack now too.

20180207_125116 by Lawrence Balls, on Flickr

20180207_125116 by Lawrence Balls, on Flickr

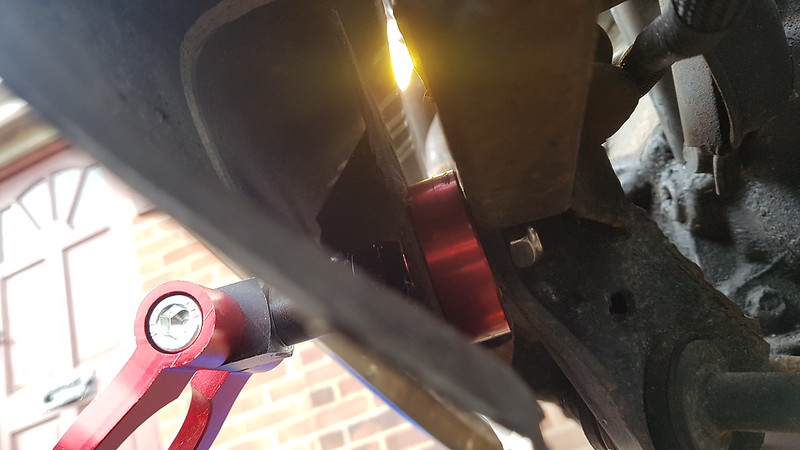

fitting the speed sensor for the digidash

20180207_131444 by Lawrence Balls, on Flickr

20180207_131444 by Lawrence Balls, on Flickr

mount being made

20180207_132456 by Lawrence Balls, on Flickr

20180207_132456 by Lawrence Balls, on Flickr

painted

20180207_141353 by Lawrence Balls, on Flickr

20180207_141353 by Lawrence Balls, on Flickr

tabs welded to the drum

20180207_151344 by Lawrence Balls, on Flickr

20180207_151344 by Lawrence Balls, on Flickr

I ran test mode and the digidash is recognising the sensor as working, just need to extend the wiring and cable tie the sensor out of the way of the shock absorber as it is a little close, so that’s the speedo nearly sorted.

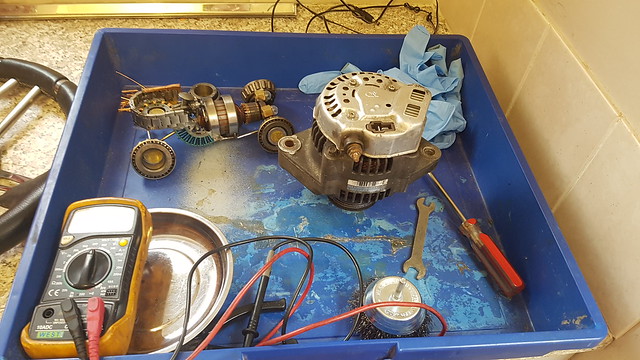

Onto the alternator, new module has arrived – The battery is on charge tonight so all being well tomorrow I will roll her back in front of the garage and get the bloody alternator working

So this afternoon observer cat was watching from the window wondering why I was messing around in the rain

20180209_154231 by Lawrence Balls, on Flickr

20180209_154231 by Lawrence Balls, on Flickr

Took off air dam

20180209_154943 by Lawrence Balls, on Flickr

20180209_154943 by Lawrence Balls, on Flickr

mocked up the tow eye, bumper and splitter

20180209_165749 by Lawrence Balls, on Flickr

20180209_165749 by Lawrence Balls, on Flickr

observer cat approved

20180209_154239 by Lawrence Balls, on Flickr

20180209_154239 by Lawrence Balls, on Flickr

made an adaptor for the tow bar

20180209_180306 by Lawrence Balls, on Flickr

20180209_180306 by Lawrence Balls, on Flickr

And finally cut some lengths of stainless to make brackets with tomorrow.

20180209_184332 by Lawrence Balls, on Flickr I contemplated bending them tonight and fiberglassing them on instead of drilling holes for bolts but decided against it as ive already bought the bolts and cba to faff about with horrible fiberglass!

20180209_184332 by Lawrence Balls, on Flickr I contemplated bending them tonight and fiberglassing them on instead of drilling holes for bolts but decided against it as ive already bought the bolts and cba to faff about with horrible fiberglass!

So plan for tomorrow

>Bumper brackets to be made

>Splitter to be fitted

>Wiring extended for speedo

>Check the output on megasquirt for tacho.

>drill out subframe mount and fit tow eye

That’s all for now folks.