So with IMM 2019 fast approaching and my motor is currently in bits @craftedclassic.

Okay so sent out my entire engine, as I had no way in removing the flywheel, the engine took about a week to be delivered but it arrived with Chris on 3rd July.

It took some work, but he managed to remove the flywheel (which is scrap) and the crank was not looking too pretty, with some fretting and the flywheel pulled a small chunk off the taper! But due to time constraints and costs of a billet crank, we decided to clean the taper up and replace the flywheel assembly.

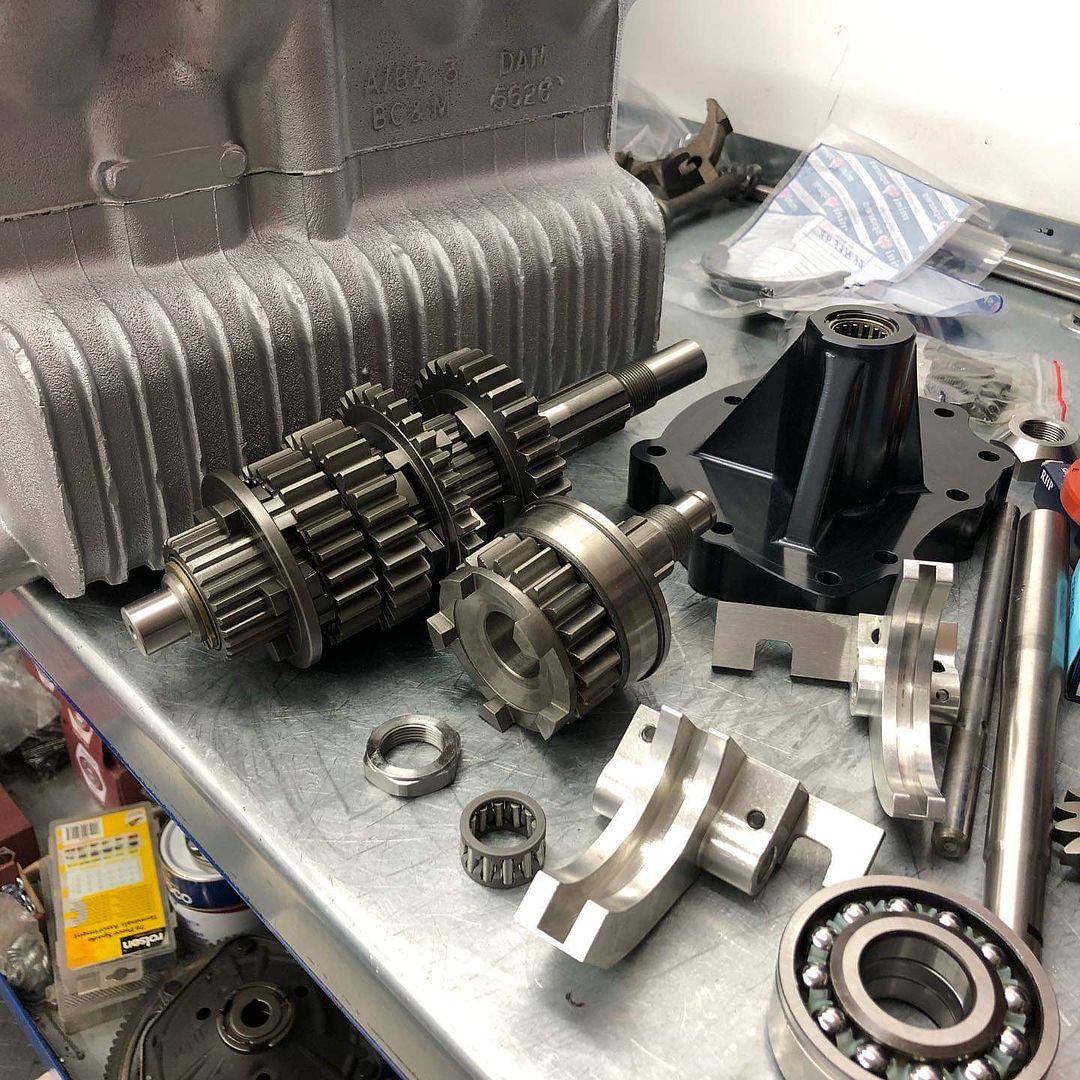

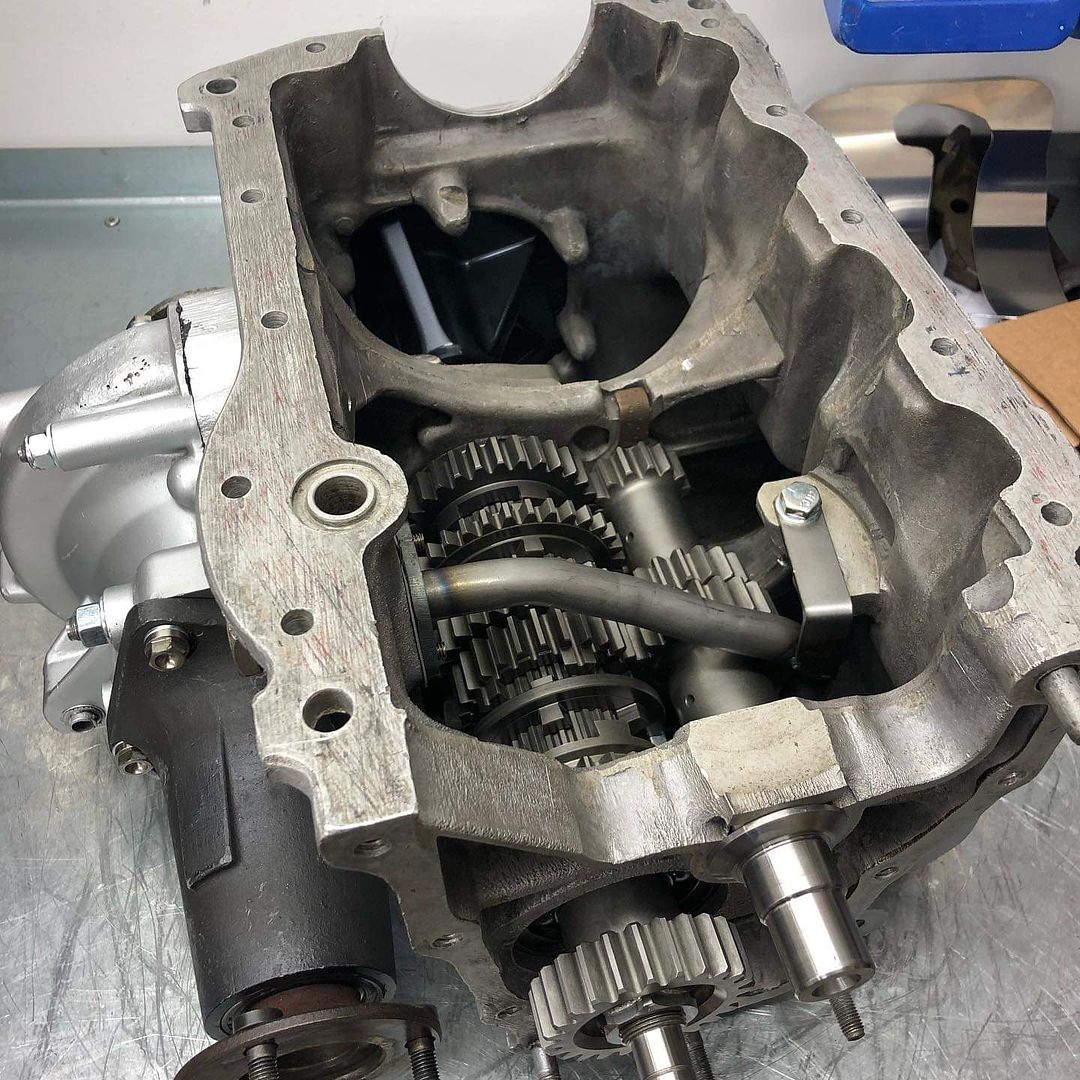

So parts sent to MED to be matched and balanced to the new flywheel, but in inspection the back plate is bent/twisted, so along with a new flywheel, paddle clutch, back plate and my grey cover. in the meantime Chris pulls apart the box to install the MED dogbox and pinion support. I also ask him to replace the headbolts with ARP, as the ones fitted are minispares (which are okay) and fit a new multi layer gasket, good thing he did as the block and head were close to blowing through!!!! As well as that my roller rocker gear has seen better days and will be replaced at a later date.

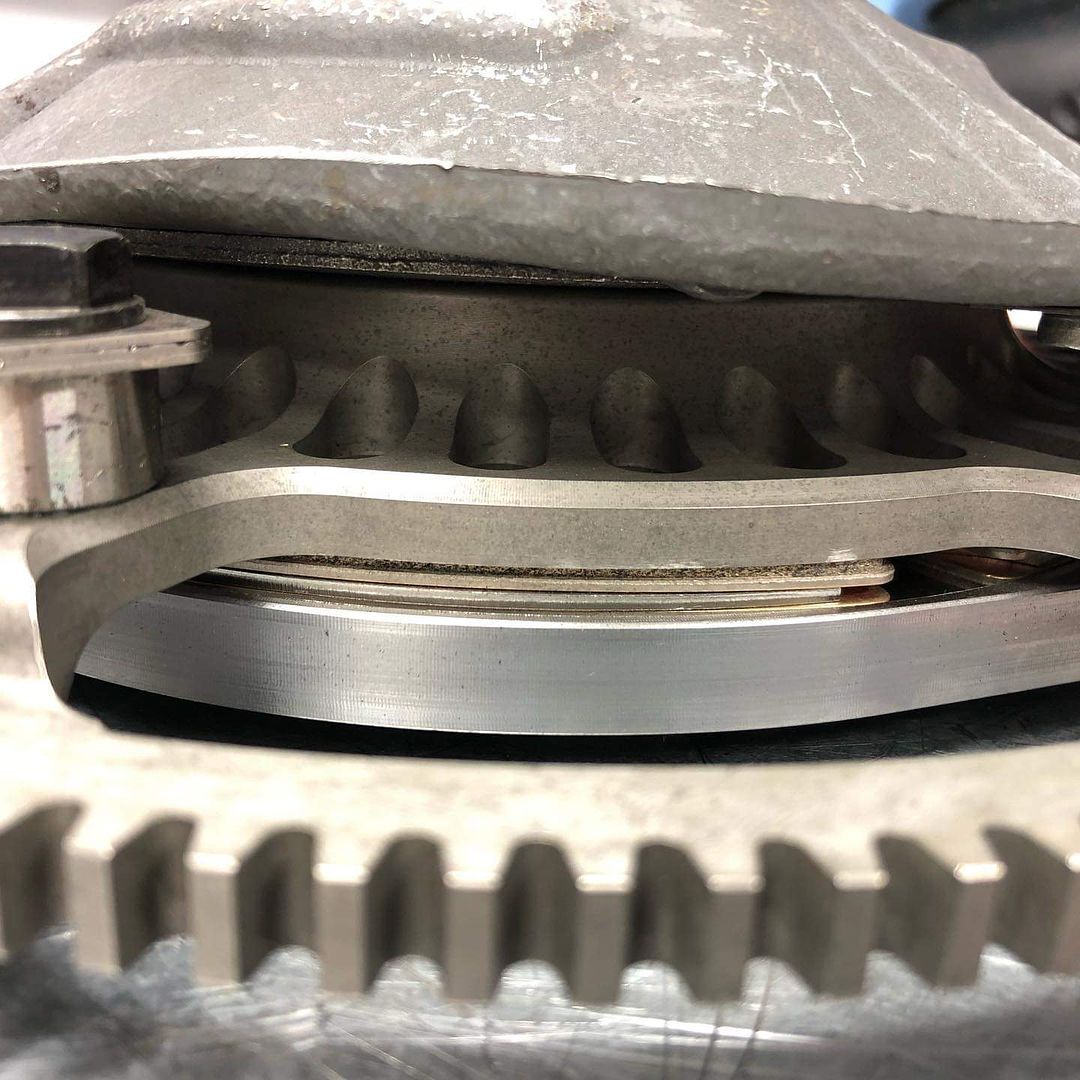

With putting the bell housing back on etc and checking the end float.....hmmmmmm twice the maximum tolerance  of end float.. the thrust washers looked okay on inspection...so he is now pulling all back apart to replace the thrust washers.

of end float.. the thrust washers looked okay on inspection...so he is now pulling all back apart to replace the thrust washers.

So I'm hoping that all goes well and that I get the engine back in time so I can bring it along to IMM, otherwise I will be turning up in a Bini

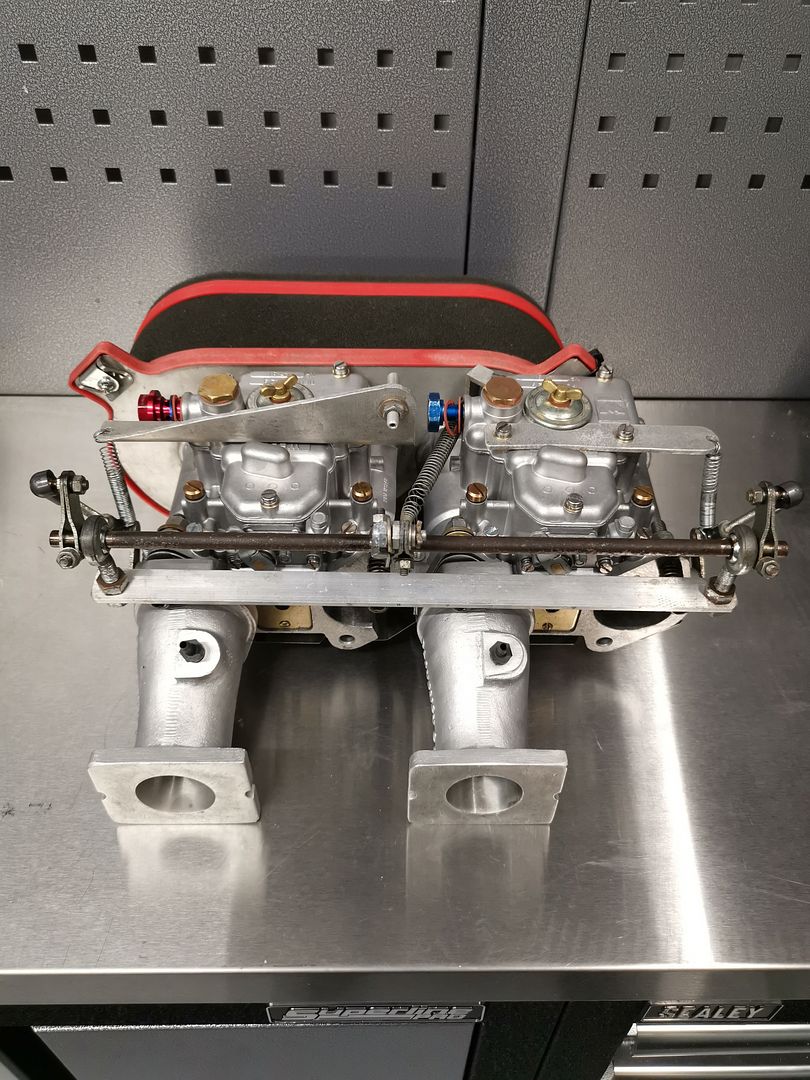

Oh and I also had my split 45 webers fully reconditioned and they look amazing.

Cheers

Kev

![]()