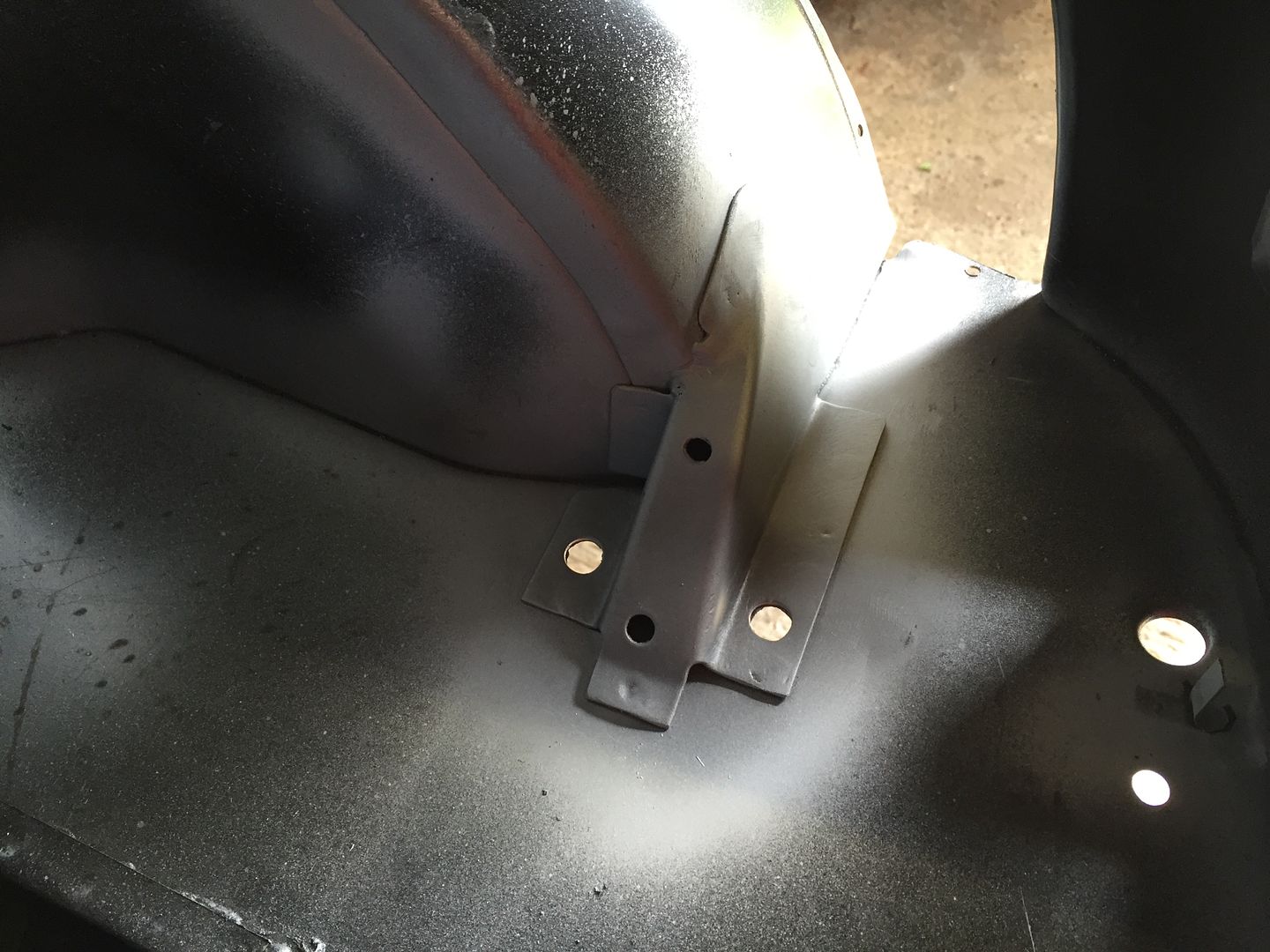

Pinned the arch in place and then offered up the quarter panel and arch close out panel, not good so after a few tweaks here and there it all lined up nicely.

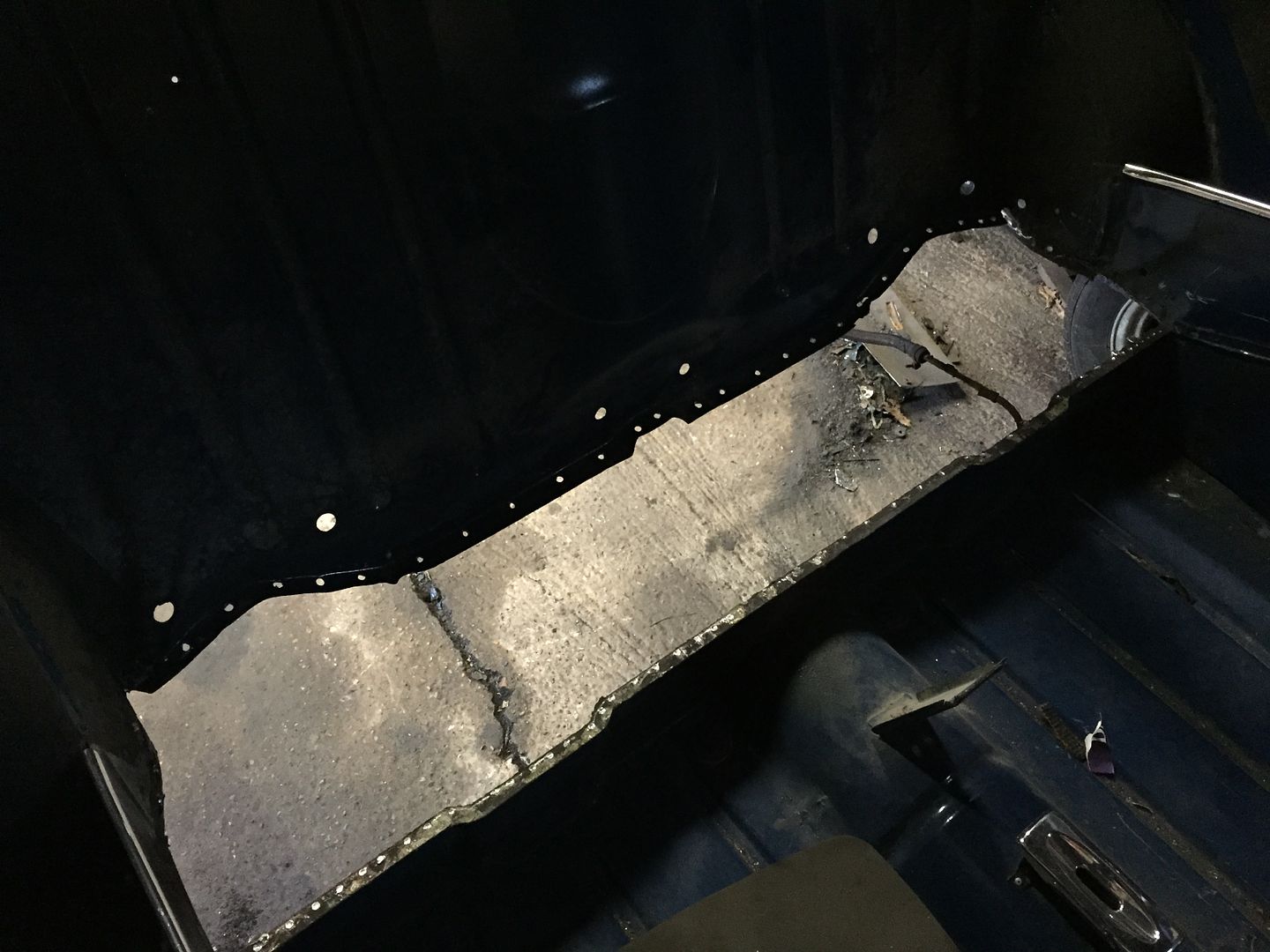

So the arch got a good dose of welding and ended up looking like this

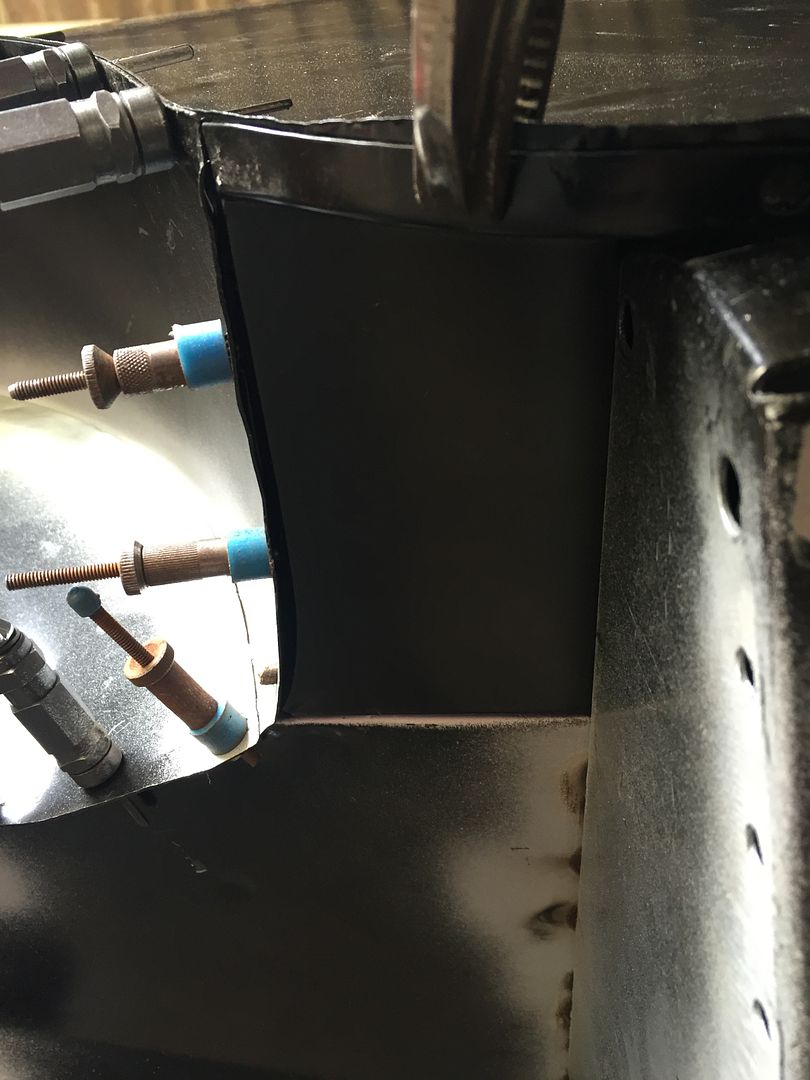

Chucked a wee patch into the bulkhead after the damage i caused getting the arch and everything else off. Just needs a good cleaning up then it will be time to weld the whole thing in. Then it will time to repeat on the other side.