Appears to have had a front ender at some point.

Edited by bettzy64, 27 March 2011 - 08:53 PM.

Posted 27 March 2011 - 07:24 PM

Edited by bettzy64, 27 March 2011 - 08:53 PM.

Posted 27 March 2011 - 08:26 PM

Posted 27 March 2011 - 08:43 PM

Posted 27 March 2011 - 09:11 PM

Posted 27 March 2011 - 09:31 PM

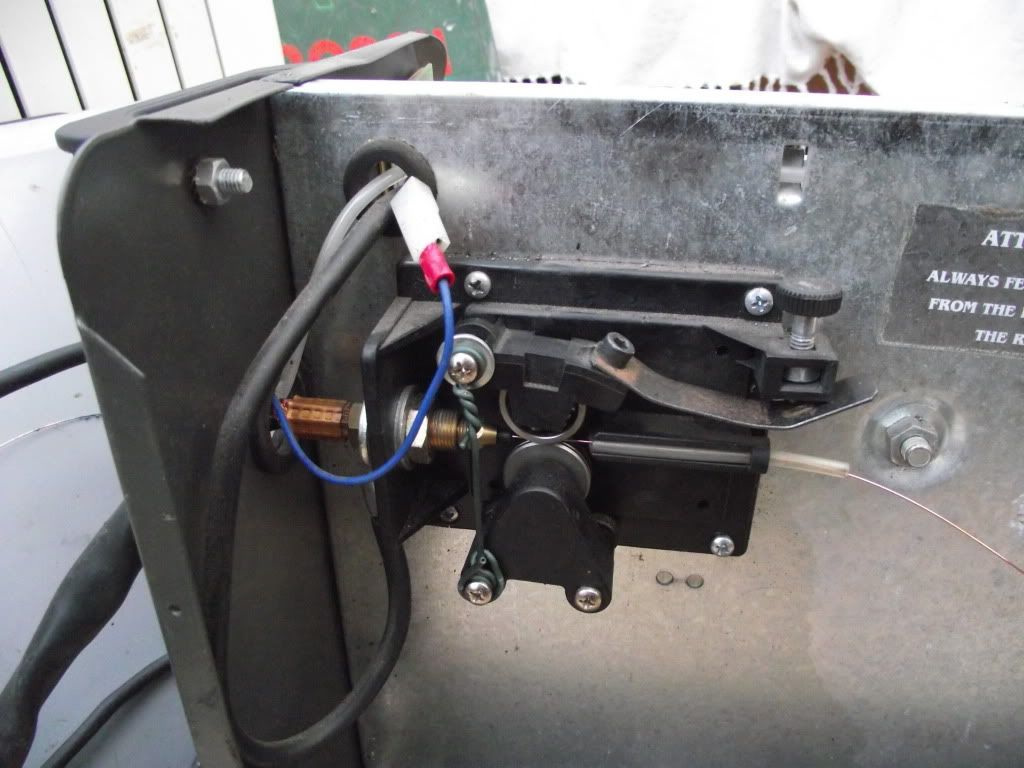

I have the same welder, and i also seem to remember having to mess about with the wire feed/ wire feed wiring. as well as replacing the trigger.

but its been absolutely fine other than that, welding up its third car at the moment as well as countless trailers, go karts, bike frames etc.

Ive been on a blackbird, and jeeeze there quick.

best of luck.

Posted 27 March 2011 - 09:59 PM

Posted 02 April 2011 - 01:10 PM

Posted 03 April 2011 - 11:39 AM

Posted 03 April 2011 - 10:16 PM

Do those two button head screws hold the hub to the trailing arm?

Posted 04 April 2011 - 09:11 AM

0 members, 0 guests, 0 anonymous users