Mpi Firing Order Off. Injection Wizards, Help Needed...

#16

Posted 10 May 2011 - 05:16 PM

#17

Posted 10 May 2011 - 05:18 PM

#18

Posted 10 May 2011 - 05:38 PM

Is there a way to check the flywheel by removing the starter motor? Before I start pulling the thing apart?!

#19

Posted 10 May 2011 - 06:01 PM

Bottom line. If the flywheel is completely installed with the locating dowels and key washer in there correct position, it is not the problem, so don't start looking for one. If on the other hand, you are completely unsure if the clutch and flywheel have been assembled correctly, you will have to disassemble it and check.

Like I previously said, I have seen the key washer fitted with the groove in the flywheel and crank not lining up. The bolt was FT and the lock tab was knocked over. Basically, the person who installed it was the the real problem, and the engine cutting out with throttle was a symptom.

The other problem that is common is people do not realise that there is a difference between the Valeo and AP pressure plates the presents the reluctor ring in the back of the flywheel to the crank position sensor, at a different angle. Just looking at both types is difficult to see any difference, but it is there. The Injection clutch is a Valeo type. Fitting an AP WILL cause you problems without further modifications to the flywheel.

This is highly unlikely to be your problem if it is the original clutch set up and has not been messed with.

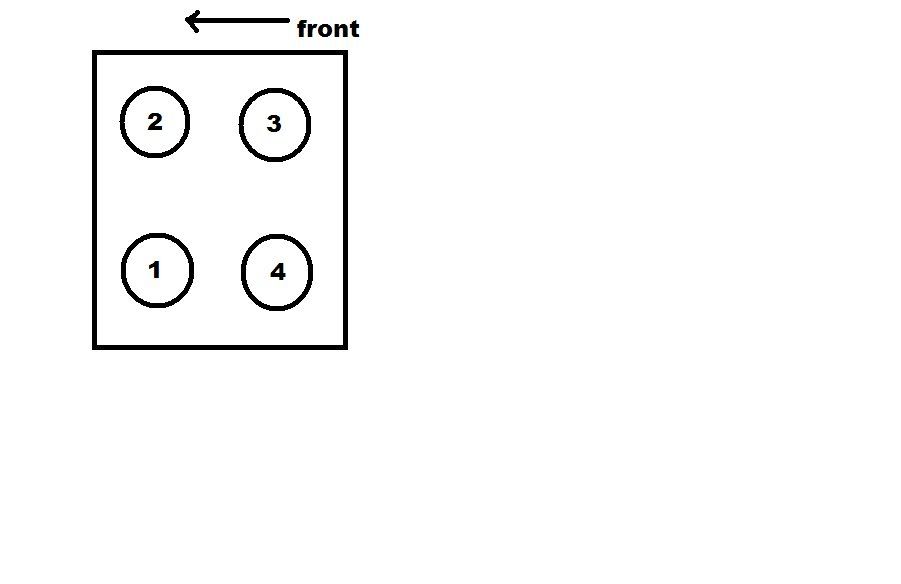

Install the HT leads as they are numbered on the coil pack with number one cylinder on the right and number 4 on the left. Cylinders 1/4 should fire together and cylinders 2/3 should fire together

For an over fueling and backfire problem I would be looking at a problem with the MAP sensor. Get it hooked up to a diagnostic and check that all the sensors are working correctly.

#20

Posted 10 May 2011 - 06:11 PM

as far as i remember u cant put the flywheel on the wrong way round, if u recon the timing is reverse ud have to change it the timing chain end which u can do in car but is awkward

How can the cam timing be 180 degrees out with the dots on the timing gear being in line? This of course all depends on who built the engine, what timing gear has been installed and how it was timed in in this case.

#21

Posted 10 May 2011 - 06:18 PM

Im near sure it can be put on upside down. It would damage the washer.

It all depends what you mean by 'can' since the key washer is designed to ensure that when parts are fitted correctly, that it CANNOT be fitted 'upside down'

The problem is if the parts are installed incorrectly. Now if that is what you mean by being fitted upside down or 180 degrees out..............................

Time to pull it apart

#22

Posted 10 May 2011 - 06:24 PM

There isn't a woodruff key for the flywheel (unlike the front pulley), however there is a slot in the end of the crank (as on all minis) which allows the keyed washer which goes under the flywheel bolt to prevent the flywheel from spinning on the shaft (in theory) However because the slot goes right across the shaft you can fit the flywheel on either way up.

To be fair to whoever did it, the manuals (even the Rover one) don't really describe this, you have to study the drawings carefully to see the subtle difference between top and bottom. And obviously on carb cars it doesn't matter which way up it goes.

This is whats happened with me. I had slotted the washer into the end of the crank ok, but the flywheel can be 1 of 2 ways.

I hope this makes it clearer.

#23

Posted 10 May 2011 - 07:03 PM

#24

Posted 10 May 2011 - 10:33 PM

Firing order should be

#25

Posted 10 May 2011 - 11:52 PM

#26

Posted 10 May 2011 - 11:54 PM

have you bolted ther coil in upside down?

Firing order should be

What does it matter which way it is fitted if you fit the HT leads as the numbers on the coil suggest? You cannot go wrong. Evidently you can

#27

Posted 10 June 2011 - 10:04 AM

The oil leak was coming from the plate behind the timing cover. Few new bolts and gaskets and fingers crossed should be fine. Also noticed my clutch cylinder had leaked so new one ordered. It has obviously lifted paint on the sub frame so that's for another day.

So 2 years on and I've found the problem. Lesson learned! I'll not get back to it until Tuesday next week, so fingers crossed I get to drive me engine as it should be since I haven't from it was rebuilt. Excited to say the least. Then mot time, my plan is to use it every day, it's a waste for it to be sitting about like a toy.

#28

Posted 10 June 2011 - 10:26 AM

#29

Posted 10 June 2011 - 11:29 AM

Edited by tony kenobi, 10 June 2011 - 11:30 AM.

#30

Posted 10 June 2011 - 01:47 PM

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users