Thought it was about time I started a project thread seeing as everything regarding this build will be getting under way shorlty, so.......

Originally my mini had a fast road 998 engine including 276 cam, fully worked 12g295 head, close ratio box, sc drops etc but it eventually the engine started to smoke and had loads of blowby. After looking at how much it would roughly cost to re-build my 998 I decided to go down the 1275 route due to the fact that I'd get more power for my money. Whilst I loved my 998 it was really lacking in the way of torque and it had to be tonked to get it anywhere and I wanted a motor with more torque for the roads, hence........ bring on the 1310cc build!

This is my mini it will be going in to.......

Ok, so the engine spec should be somewhere along the lines of:

Cylinder Head:

12G940 "stage 3" spec head (11 stud)

35.7mm intake and 29.4mm exhaust plasma nitrated valves (single collar retention)

180lb double valve springs and bronze valve guides

Fully Gas flowed (keeping the intake ports a sensible size to aid low down torque)

Hardened Valve seats suitable for unleaded fuel

Minisport 1.3 ratio roller tipped rockers

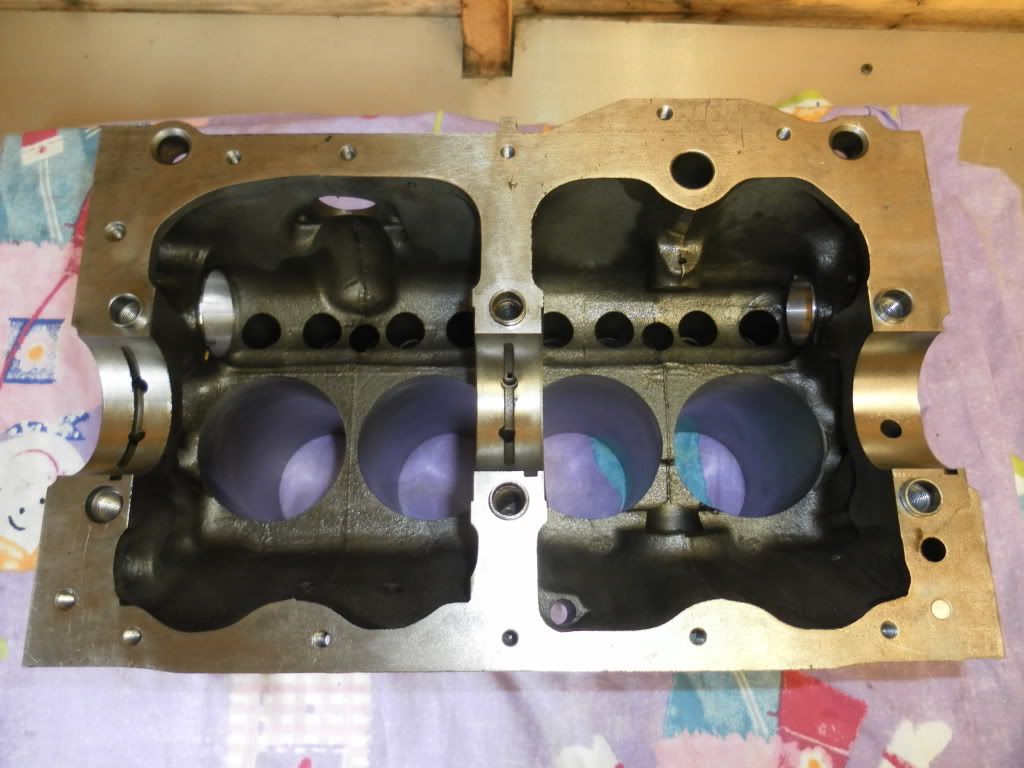

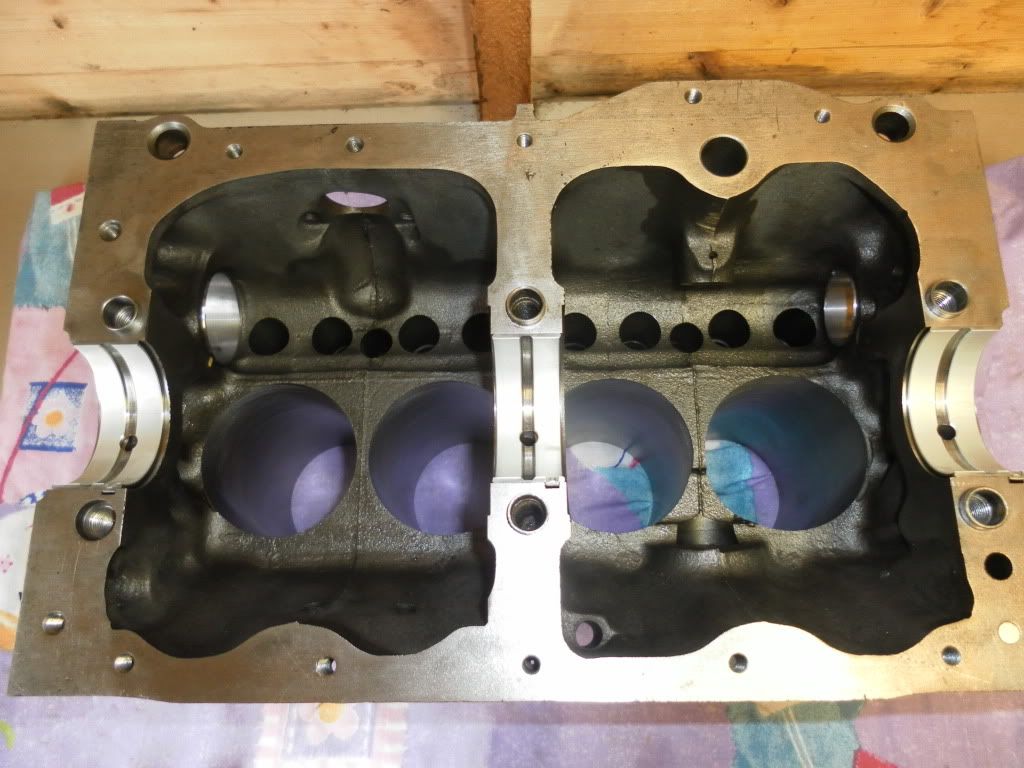

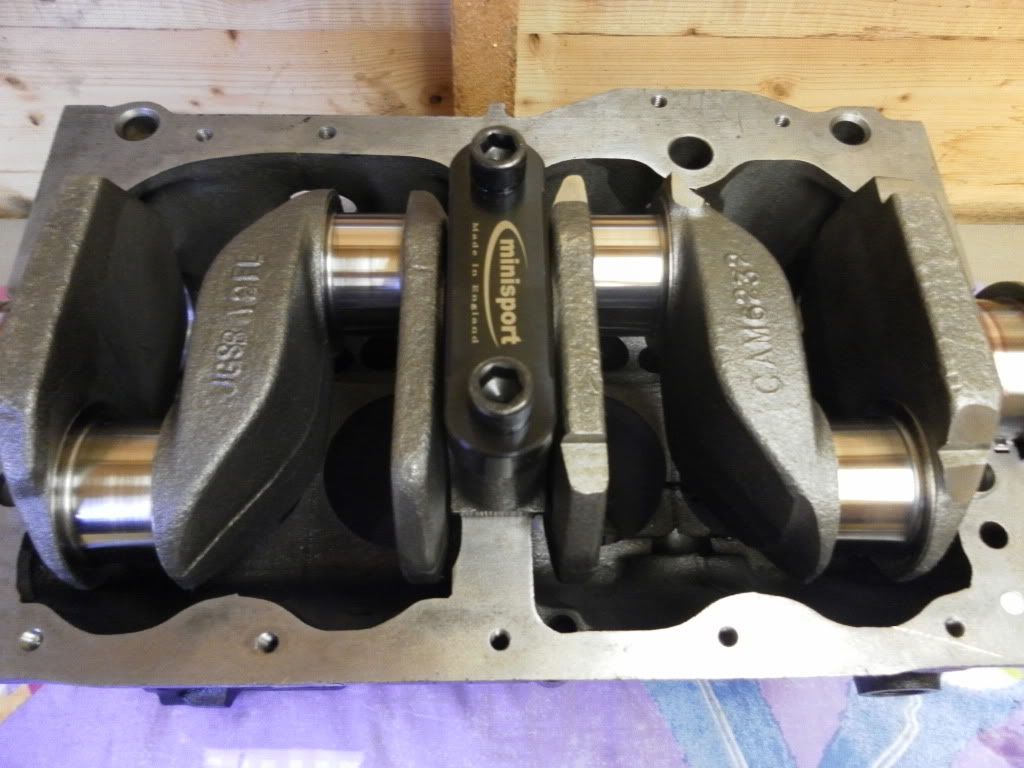

Engine Block:

1310cc A+ Plus Block (Drilled for 11 stud)

Crank re-ground 10thou on mains and 10 thou on big ends, crack tested and dynamically balanced

Centre Main Strap

A+ rods, crack tested and size and alignment checked, individually balanced end over end

AE 21253 +40 High Compression pistons, individually balanced and fitted to rods

Quality Glacier shell bearings and thrust washers

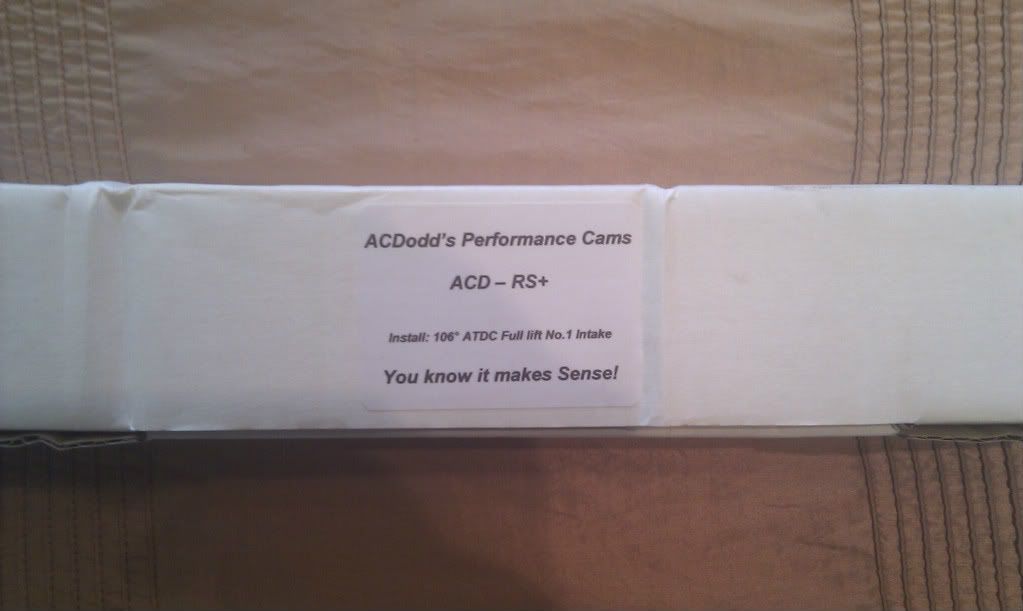

AC Dodd RS+ 270 duration cam and minispares follwers (similar to the Kent 276 and PH3)

Steel Backed oil pump

Minispares Lightened Duplex Timing Gears

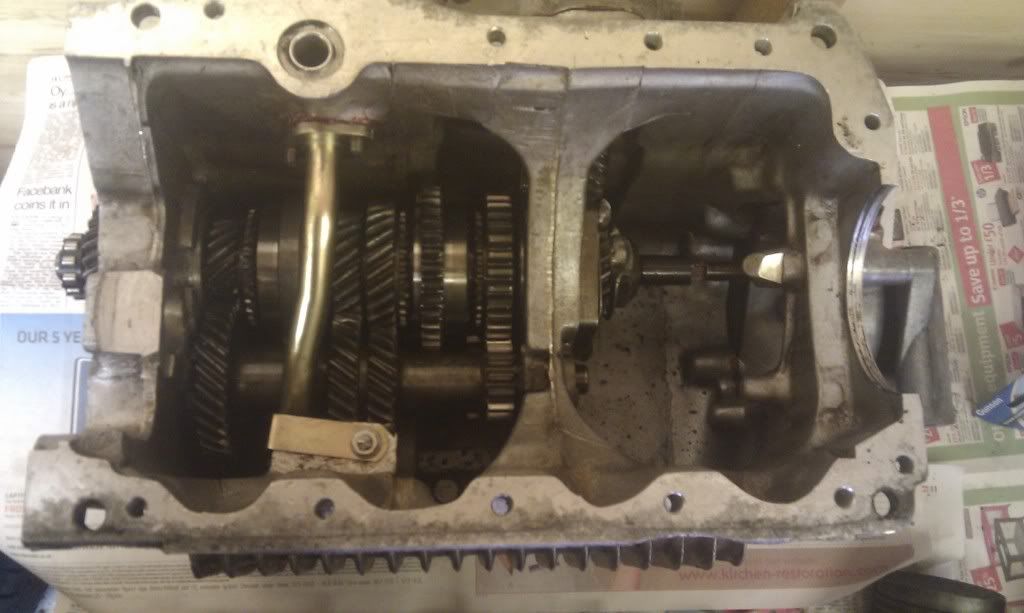

Gearbox:

Rebuilt A+ gearbox with 3.44 final drive

Rebuilt diff with Guessworks Molybdenum competition diff pin and planet gears

Guessworks Central Oil Pick-up Pipe

Here is the doner engine; A 46k miles Sprite A+ Unit

The Block and Crank should be back sometime this week.

Ash

Edited by miniman92, 21 January 2012 - 02:23 PM.