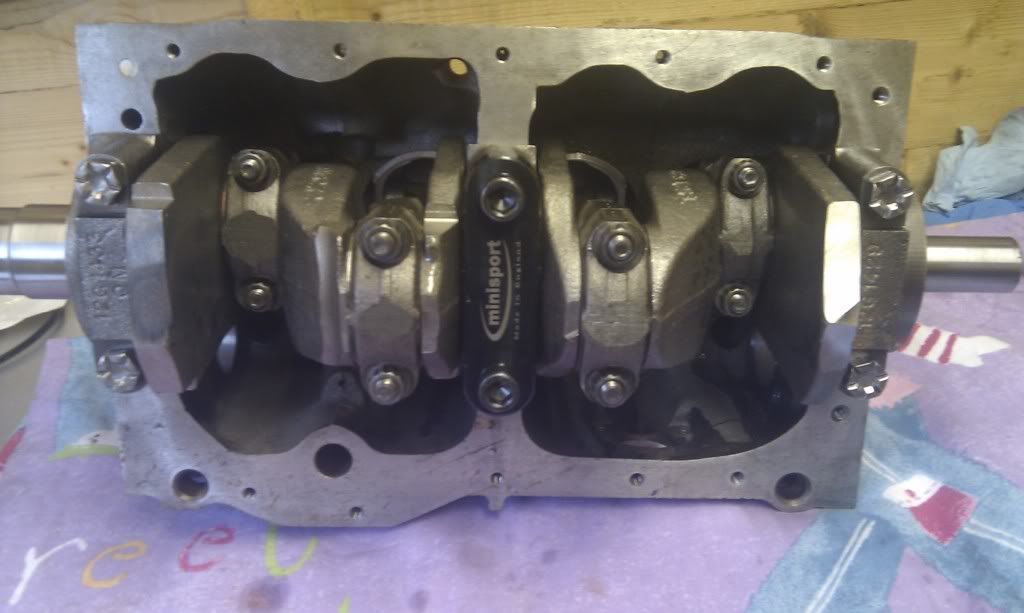

My 1310Cc Engine Build

#16

Posted 07 February 2012 - 06:57 PM

#17

Posted 07 February 2012 - 08:49 PM

I have just used a micrometer caliper to make sure it's even. A feeler gauge to check the clearance afterwards.... I am just worried about not being able to achieve a uniform finish without any taper which I presume is hard to do by hand?

Ash

#18

Posted 09 February 2012 - 06:58 PM

Standard size thrust:

Oversized thrusts:

I just cant way it up. Does anybody know if standard size 998 thrust washers are thicker than 1275 ones?

My only theory is that minisport have sent me some .005" oversized thrusts for a 998 and not a 1275?

I tried for an hour to using some 600 grit wet and dry but it doesnt seem to do anything much at all!

Ash

#19

Posted 01 April 2012 - 12:51 PM

I now have a crank end float of .004".

All of the pistons are now in...

Cam and followers are in, the backplate is on, lightened duplex fitted and cam timing checked. Photobucket isn't playing ball so will upload some more pictures later on.

Cam timing is currently at 107.5 and I need 104 (taking in to account chain stretch,) so I need to get hold of a 4 degree woodruff key.

Also checked my idler gear end float and I need a 136-137 thou idler thrust washer, has anyone got one they want to sell?

Once I've got these bits then its just a case of mating the engine to the gearbox and finding a nice modified cylinder head with 22.8cc chambers. A nice cylinder head from the likes of SRE is going to cost around £500 so might have to find one second hand and have the chambers opened up, we shall have to wait and see!

Ash

#20

Posted 01 April 2012 - 05:15 PM

Stunning clubman by the way, do u have a link to your build?

Cheers

Kevin

#21

Posted 02 April 2012 - 07:29 PM

#22

Posted 02 April 2012 - 10:45 PM

It is great to see an engine being built carefully, thoroughly and properly.

#23

Posted 02 April 2012 - 10:52 PM

p.s. As you checked the end float so well did you also check the bearing clearances with plastigauge or any other method? This will be a good thread and your engine build is almost identical to mine which I haven't started yet! (Minisport block too which has been double checked and bore/machining tolerances are perfect!)

Edited by C4NN0N, 02 April 2012 - 10:59 PM.

#24

Posted 03 April 2012 - 03:13 PM

C4NN0N, the main reason I chose a standard lightened duplex and woodruff key is mainly due to cost. I don't see the point in spending all that money on a vernier duplex when woodruff keys are so cheap! To be fair though, I've heard great things about swiftune and piper vernier duplex gears; they are race proven so I don't think reliability is much of an issue with them..... but I see where you are coming from.

I checked the sizes of the crank journals using my vernier gauge, and the crank was tightened down in three stages (20, 40 and then 65 lb.ft) to check for any line bore problems after each cap was tightened down. The crank was nice and smooth and could be turned using finger and thumb on each end...... so everything is good so far!

#25

Posted 25 April 2012 - 06:44 PM

#26

Posted 01 May 2014 - 03:32 PM

I know it's been a while since you started this project.. but how did things work out in the end, engine run ok? ![]()

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users