Shot Blast Brake Discs?

#16

Posted 05 March 2012 - 09:37 PM

#17

Posted 05 March 2012 - 09:41 PM

#18

Posted 05 March 2012 - 09:55 PM

#19

Posted 05 March 2012 - 10:02 PM

#20

Posted 06 March 2012 - 10:42 AM

But if it was simple rusting all over, I would try something different, the electrolytic treatment, using sodium bicarbonate, as has been shown working on various steel bits in at least one build thread, followed by careful use of the brakes until the pads finished the job.

I seriously doubt that blasting would damage the disks, unless overdone, but it can't get them flat and parallel if there is a non-uniformity caused by the pads.

#21

Posted 06 March 2012 - 05:57 PM

#22

Posted 06 March 2012 - 06:51 PM

I had a body shell shot blasted a while ago by a company with massive industrial blasters, and not a single part was warped (I did not have the roof or quarters done) but what they did was approx 1.5mm thick and no warping so how anyone can say some sand coming out at 80psi will warp a 10mm thick lump of steel is beyond me, and as Martin said any pitting will be done by the rust not the blasting (apart from a tiny amount of surface dulling which is minute pitting).

Personally I would wire brush them to get the loose off, then give them a going over with some glass bead or fine sand, followed by a good clean. Once they have warmed up and been used a few times they will be as good as any other, unless they are rusted majorly!

#23

Posted 06 March 2012 - 07:09 PM

I would put money on shot blasting in a home type cabinet not damaging the discs, in fact I'd put £500 on it straight up.

I had a body shell shot blasted a while ago by a company with massive industrial blasters, and not a single part was warped (I did not have the roof or quarters done) but what they did was approx 1.5mm thick and no warping so how anyone can say some sand coming out at 80psi will warp a 10mm thick lump of steel is beyond me, and as Martin said any pitting will be done by the rust not the blasting (apart from a tiny amount of surface dulling which is minute pitting).

Personally I would wire brush them to get the loose off, then give them a going over with some glass bead or fine sand, followed by a good clean. Once they have warmed up and been used a few times they will be as good as any other, unless they are rusted majorly!

When I say warped, It is meant in the sense that the brake rotor surface is not even, Not warping as in bending the rotor, otherwise i would have stated that, and which you said, would be very very unlikely.

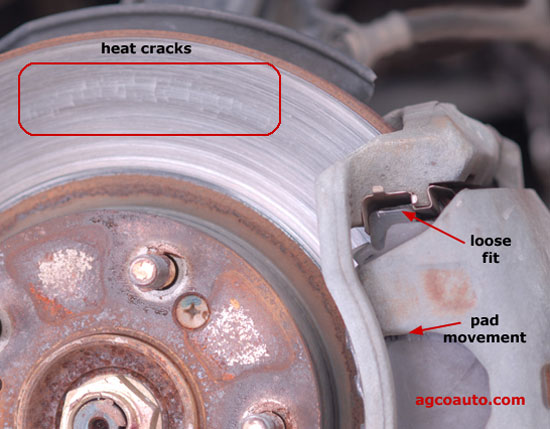

The "warping" I am talking about is where you have uneven transfer of the brake pad material on the disk. The cause of this is having "high spots" on the rotor itself. if you hand shot blast them, you will not get an even surface as some areas of the disk may have more shot treatment than other (even if you try your hardest not too) and will leave high spots. High spots can then cause this "warping" and in some serious cases, case cracking of the rotor itself, see picture:

Machine shot blasting with a shot blasting line will reduce the likelihood of this happening but again, it can still happen. Obviously there are other causes for heat cracks in rotors but this is one cause.

As i stated before, to make sure your disks are true and free of "high spots", the lathe is one of the best ways to go! Or, buy new rotors and pads.

Lewis

#24

Posted 06 March 2012 - 07:46 PM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users