taken from a post in another forum, hope it helps

"I've done two myself, and used the method described by Vizard in the 'How to Modify Your Mini' book.

Done properly, it will be strong and, according to Dr Vizard, your Mini will lose over 40 square inches of frontal area. Not an insignificant amount when you consider how aerodynamically alike the Mini and a housebrick are!

I left the roof seam for the reason mentioned - it keeps the water from pouring down your neck as you get out.

Mycarsbothe featured removable steel front ends, so I only deseamed the pillar sections; I needed the A-panel seam to butt the wing edge up to.

I also think the bumper seams are a matter of preference. One I did with, one without. Both looked extremely good IMHO.

As for the method, I stripped out all the interior, including headlining, wiring, glass and fuel tank. Don't forget the little bits of foam that Leyland stuck everywhere to soak up water! They burn very well. Ask me how I know this!

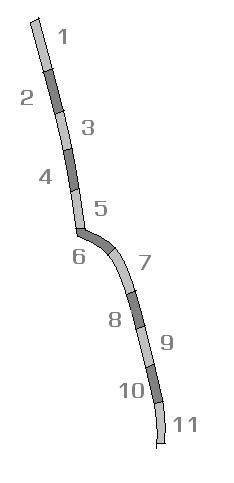

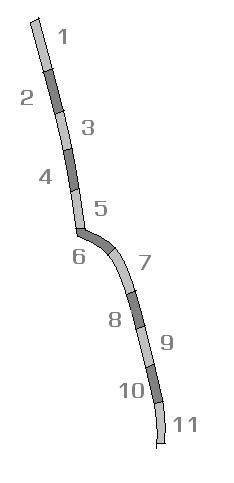

Remove the seam finishers, and mark the seam at 6 inch (150mm) intervals. Like this...

Then with a hacksaw, cut through the seam down to the body at each mark. Starting at the top of the pillar, leave the first 6 inch section - No 1, and grind away no 2 so it's almost flush with the bodywork. You should have a small ridge of metal from each body panel exposed. this should be gently beaten inwards with a flat body hammer until it is just below the level of the surrounding metal work. This can now be welded. Don't forget to remove the wiring from the left hand A pillar - it will catch fire. Ask me how I know this too!

While that is cooling down, you can start on grinding no 4 section. Doing it this way means that the poor unsuspecting Mini won't spring apart when you cut it! Once you've ground and welded your alternate (even numbered) seam sections, go back to the first one you left, and fill in the gaps with the odd numbered sections.

Once they're welded, you can go inside the car (only at the back of course - you can't weld inside the front pillars!) and once you've removed the seam sealer and paint, weld small parts of the seams, but don't dwell too long, and move around to minimise distortion.

This will be stronger and no less waterproof than the original. Depending on how carefully you welded and how gentle you were with the hammer, a slight skim of filler will put the contours back into your Mini.

Point of interest. Some Minis don't deseam too well. Go to the back of your car and get down level with the waist-level body pressing. On some cars these don't line up from the factory, and it will be nearly impossible to make good the pressing where the seam used to be. Ask me how I know this as well! "