Refurbishing and rebuilding my rear subframe and started to put the radius arms back on this evening. I'm using new camber brackets. I'm doing a "loose" fit to make sure everything goes together OK - i.e. not tightening any of the bolts in the brackets yet so the bracket can float a little.

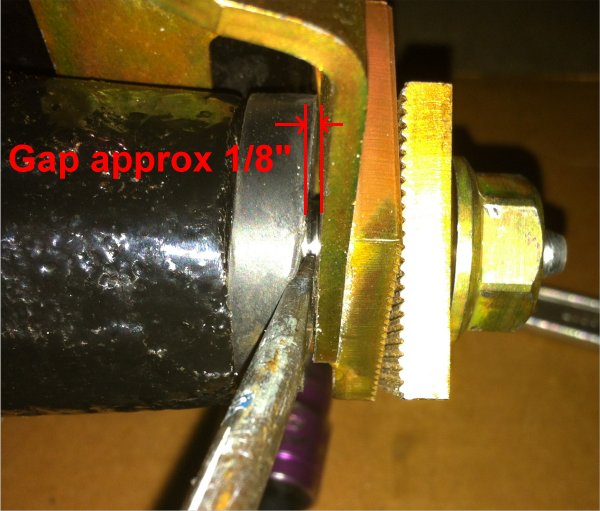

However, what I see is an approx 1/8 inch gap between the thrust washer on the end of the arm and the camber bracket... even if the bracket is push inwards as far as it will go (see picture below). Is that normal, or should I put an 1/8 inch additional washer in the gap (one with a diameter larger than the rubber seal ring)??? The gap does close when everything is torqued up... but only because the bracket is bending slightly.

Please put my mind at ease

Note: I've tried three sets of brackets from different suppliers (the original but knackered/unusable fixed brackets, camber adjustable, and toe/camber adjustable) and all show the same issue.

Also... yes I know many will say "don't use adjustable brackets - modify a fixed set to your geometry requirements"... yes I could do that, but I don't have a good set of fixed brackets to hand. I'm going to use the Minisport toe/camber ones in the picture, then when I'm happy with the geometry I'll weld the slotted adjustment plate in place.

Cheers,

Colin.