Its been a while since I updated this. Not a lot has been done unfortunately as a few things have come up (trying to buy a house is one of them), but it has progressed a little bit.

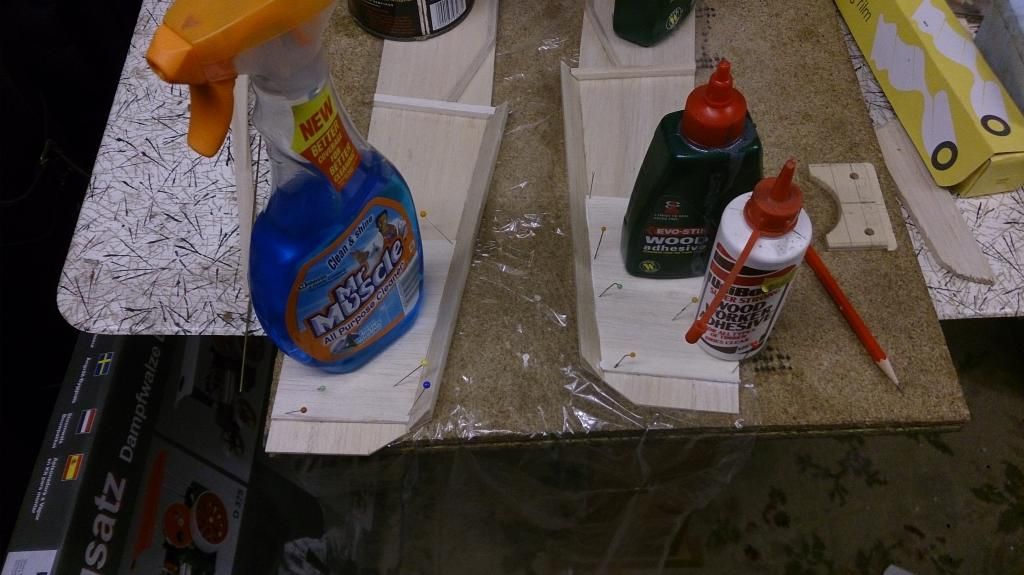

First of all I glued in the reinforcement pieces to the rudder and elevator. This is where the control horns fit. If you fitted them directly to the balsa wood it would just crush it as you put the controls in to fly it.

I also marked out and cut the two sides. Well almost cut the sides out. I still need to sand the wing's leading edge to shape and cut the wing seat out. The tail plane seat gets cut out once the two sides of the fuselage is joined together to ensure they line up perfectly. The side of the plane is over 4" wide so an extra piece has to be glued and joined onto the top at the front of the fuselage sides. I have purposely made it too long so it can be trimmed along with the wing seat.

I then glued in some of the reinforcement pieces that make up the sides.

I then glued in the 1/4" x 1/4" triangular reinforcement strip along the bottom edge.

I didn't have any 1/4" x 1/4" triangular so ended up sanding the edge of a 1/4" sheet to shape and then trimming it off. I've only had time to do enough for one side.

I think I will also have to modify the bottom edge of the fuselage at the rear. The plans show a tail wheel that is mounted on a piece of wire that acts as the hinge of the rudder. The piece of wire also connects into the rudder so as the rudder turns the tail wheel moves with it. This is perfectly normal for RC and full size planes. The issue I have with this is that there is no give between the wheel and the rudder. When flying off grass this set up would be fine but not when you fly off a tarmac runway that has loads of little potholes and joints in it, they tend to grab hold of the tail wheel unexpectedly.

The solution is to mount the wheel and put a spring between it and the rudder. This means as the rudder moves the wheel moves with it but if it hits something (crack, pothole, stone, etc) the spring stretches rather than the rudder being wrenched to one side, pulling the control wires and stripping the gears in the servo that controls it.

Again the above is fine but it only works if the rudder goes all the way down to the bottom of the fuselage. On the alco frolic it doesn't. Hmmm... I need to think about this one for a bit.