Gearbox

#1

Posted 26 July 2015 - 08:23 AM

thank you

#2

Posted 26 July 2015 - 08:39 AM

Road car?

Well the only advantage is you'll have a legitimate excuse for not listening to the wife.

There was a recent thread (I think in Chat) on pretty much this topic.

#3

Posted 26 July 2015 - 09:02 AM

#4

Posted 26 July 2015 - 09:51 AM

#5

Posted 26 July 2015 - 10:38 AM

Steve, I think you mentioned that the Straight cuts, you feel are stronger than helicals in the other thread. Could you shed some light on your thinking here?

#6

Posted 26 July 2015 - 10:59 AM

#7

Posted 26 July 2015 - 11:08 AM

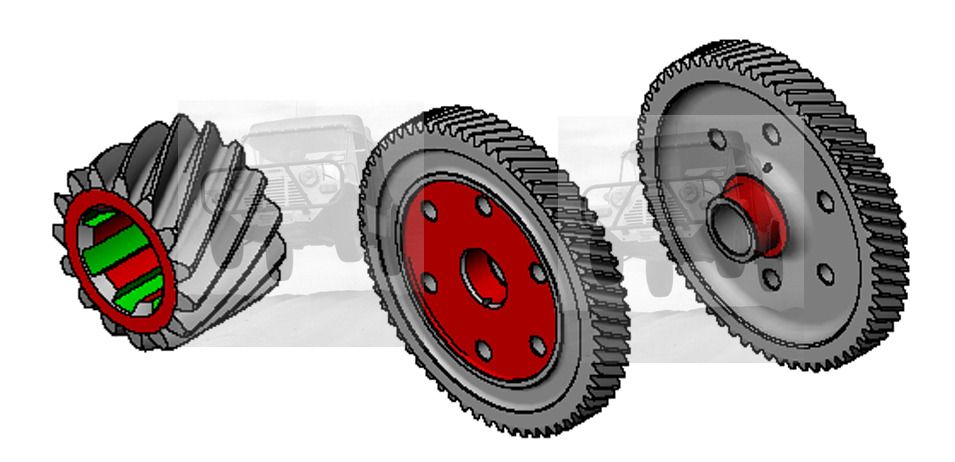

hi all can someone tell me what is the benefits of have a Straight Cut Close Ratio Gearbox. With a Crown Wheel and Pinion

thank you

The only gain is you can have the right set of gears for the use you want. There is only losses in having a straight cut FD which is why most are semi helical as you get some strength back by having a longer tooth root and are still reasonably priced.

There has for years been talk that the straight cut gears produce less side loads and therefor allow more power to be transmitted through the box. But the losses of a helical gear set as minimal anyway.

So why are you looking at one?

#8

Posted 26 July 2015 - 12:13 PM

#9

Posted 26 July 2015 - 12:24 PM

#10

Posted 26 July 2015 - 03:02 PM

I have a 1430cc engine with 108ft/lbs torque. What i think it need is a better spread of gear ratios. I currently have a Metro Turbo gearbox with standard ratios. I can't help feeling first and second gear could move up a bit close to third.

Is there a set of straight cut or helical gear set that will provide a more even spread ?

Are straight cut gear that much louder even though they are submerged in engine oil ?

Aren't the straight cut drop gears move of an issue for noise ?

#11

Posted 27 July 2015 - 07:40 AM

There is proven side and axial loading through helical gearing. It is the downside to them being quiet. the overall effect will mean if the axles, bearings and gear casing aren't up to it then it will cause a failure. Whether the gear set themselves are stronger, I'm unsure. However, my dad, who used to be a transmission specialist for GKN defence, has said that tolerances are easier to monitor on straight cut gears.

Also, something you might find interesting is the contact pattern of a helical gear. On a straight cut the contact pattern is linear, on a helical cut it 'travels' across the teeth meaning the stresses/fatigue is higher.

Steve, many thanks for posting that info up.

I actually rather like the pressure patch sketch of the Helical Gear!

Sounds like your Dad had an awesome job,

Side Thrust - yes, Helicals do exhibit this down side. Same for Axial Loading, though Generally if the Gear can take Radial Loading, it will stand up to Axial Loading, but that doesn't add anything to any losses.

Also quite true of the Bearings and Cases, they have to be able to withstand Side Thrust exhibited by the Helical Gears. But let's face it, our Gearbox cases aren't exactly renown for busting out webs (sideways at least!) from thrust.

However, as I did mention in my other post, Gear for Gear - meaning gears manufactured the same way, same material, same heat treatment etc etc, Straight Cuts are weaker than Helical. There are a few reasons for this.

The Pressure patch pic you've posted up shows in part one reason. That really shows quite well that Contact Ratio between teeth, that is, the number of teeth in mesh at any one time. In that pic, it clearly shows a ratio of (near enough) 1.5:1. So, we have 1.5 Teeth in contact at any given 'moment'. In the case of Straight Cuts, they are usually only 1:1 for Contact Ratio. The best you'll ever get is about 1.1:1, but not with the tiny gears we have in our Gearboxes, they are all 1:1.

The next past comes from the Tooth angle to the axle. With a Helical, since the tooth is at an angle, it is longer and therefore has more root 'contact'. Also, because it winds over / around the gear, it spreads the load further (considerably so) around the hub of the gear, further increasing it's strength. Further, the helix create a triangular form, so it's considerably better able to withstand the bending motion from the Tooth pressure, that leads to fatigue failure.

Straights - gear for gear - have a shorter tooth and only an immediate root ie, directly under the tooth that is under pressure, with no further support, so fatigue failure will occur sooner, the root is shorter and the load instead of being distributed over the hub to any amount, is not, so any deformation in shape (from tooth pressure) will be greater. This is why in most cases Straights are cut from a higher grade material, not to make them stronger, but to try to get them as strong as helicals.

OK, so maybe I should let a bit of the cat out of the bag here. Back in the 80's, I did some work for Jack Knight Developments (a different company from that which is around today I must add, but did have some 'interaction from time to time with BMC / BL / Rover), it was to do with Mini Diffs and the Gearbox Cases. Part of the outcome of the study and advice given was for the cases, to not drill the 3rd Bolt hole for the retaining bearing in the (now older) 4 bolt type gear cases. Funnily, around 18 months later, BL did just that in the DAM 5626 Cases. More recently, I did some design work with KAD, though they were unable to produce that product with the machines they had at that time (I ended up doing those myself). Great company none the less. And just a few months ago, I again did some Gear Design work in conjunction with Holinger Engineering, awesome company and some considerable resources there. Between us, we were able to design a FD set that has a Contact Ratio of 2.93, a bit of a far cry from the 2.09 of the stock ones, while slightly reducing the helix angle. This part of what we did to increase the strength of them. Ah, another story for another day.

Edited by Moke Spider, 27 July 2015 - 08:50 AM.

#12

Posted 28 July 2015 - 06:44 AM

Is there a set of straight cut or helical gear set that will provide a more even spread ?

Watch this space....

https://www.facebook...124482804255669

#13

Posted 01 July 2016 - 04:41 PM

Is there a set of straight cut or helical gear set that will provide a more even spread ?

Watch this space....

https://www.facebook...124482804255669

Any news?

#14

Posted 01 July 2016 - 04:52 PM

ac427, other option would be to build a box with the S/GT ratios, these are a bit closer than A+

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users