I've spent tonight taking out pistons/rods, old bearings, thrusts etc from my block in readiness for having the bores honed and so on. The block is stamped 12g1279 and has a 12g1505 crank. The haynes manual hasn't got any details for this block so is there anything online I can refer to? It's also been bored to 1330.

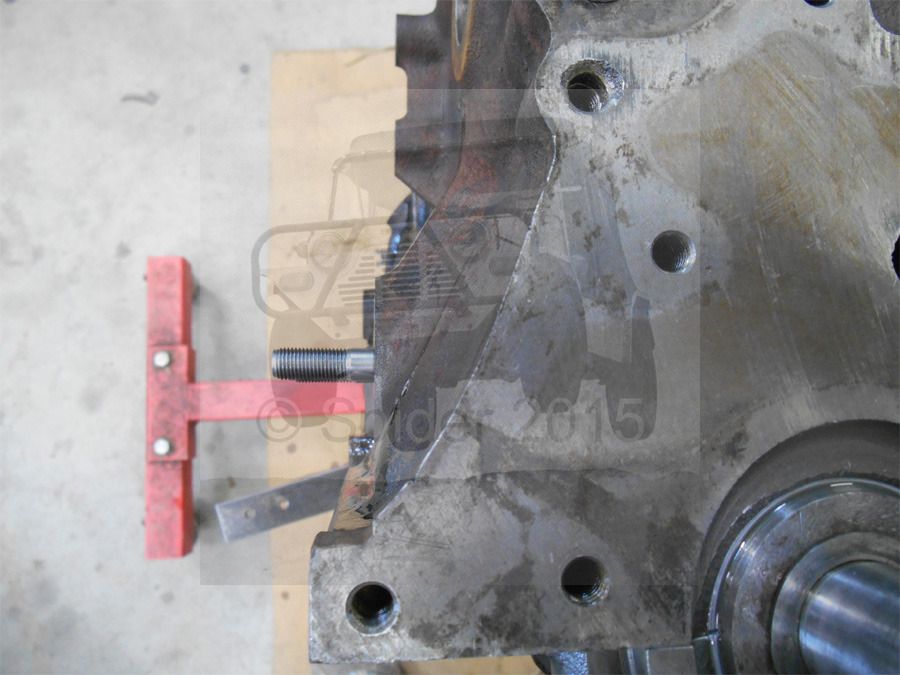

12G1279 Engine Block

#1

Posted 21 August 2015 - 08:52 PM

#2

Posted 21 August 2015 - 09:32 PM

There were 3 series in the 1275 block castings pre-A+ that I know of and I'm quite sure, this is one of them.

The early series were thin flange. These are a fairly rare. These were also machine up to take the smaller big end crank, which were thinner across the thrust faces, though it's likely that the last of them were wider, but I'm not 100% sure on this.

Later ones (not long after those ^) were basically the same, but thick flange.

The last of them were similar again to these ^ but the tell tale being an added lump to the casting for the later tensioner type timing chain set up. From the blocks I've had my hands on over the years, these were generally the best of any 1275, A+ included.

As far as putting it in to the machine shop goes, as long as the machinist follows the pre-A+ 1275 dimensions, he'll be sweet.

#3

Posted 21 August 2015 - 10:25 PM

Thanks for getting back Moke, whereabouts is this extra lump for the tensioner that you speak of? It had a single chain and tensioner fitted when I took it apart. The only thing I'm hoping to get done is some cross hatching as I've had the bores checked and was told they're fine, no step at the top of the bores either. When I took out the pistons tonight then the top rings on most if not all pf the pistons were broken! this along with highly polished bores probably explained the big puffs of blue reek! It's a right hotch potch as it came with a verto clutch and gearbox with a 2.9 ( if I remember correctly ) F.D. I've got a 3.44 to get fitted. I'll maybe source a pre verto clutch and 1275gt gearset once I've had it running for a while, maybe!

#4

Posted 21 August 2015 - 10:27 PM

There are a few other numbers on the back of the block that I'll get tomorrow that might help to narrow down the actual spec of the block.

#6

Posted 22 August 2015 - 08:19 AM

I've taken a 1275 apart recently where all of the top rings were broken, some into very small bits. In this case it had been used for rallying, and there was a lip at the top of the bore. If the top rings catch the lip at high rpm then they can break. Other reasons for ring breakage include engine seizure (more likely on air-cooled) and severe detonation.

I would suggest using one of the remaining intact rings to double-check the bore wear. Put the ring in the bore at very top, and meaure ring gap with feelers. Move down about an inch an repeat gap measurement, then same for 2 inch and 3 inch down.

Also if you're planning to re-ring the existing pistons check the ring lands for wear, the piston rings must be a close fit.

And further down the block check fit of main bearing caps on the dowels, these should be tight. Particularly the centre cap.

#7

Posted 22 August 2015 - 09:16 AM

Thanks for the advice Carbon. How much difference is acceptable when measuring using the rings and feeler gauge method? I've been advised to do this along with checking the ring lands on the pistons, again what would be the maximum wear allowed regarding this or will it depend on what make of rings I use? I'll have another look at the mains caps later but I seem to remember that they were a tight fit last night, though I had had a couple of beers by that stage! I had a quick look at the block this morning Moke and it appears it's a 76 to 79 block.

#8

Posted 22 August 2015 - 09:20 AM

Just like to add that the block has been checked at a local engineering firm by a very trusted and experienced engineer who said the bores and top of the block is in good condition but I think I'll try checking it just out of interest.

#9

Posted 22 August 2015 - 09:23 AM

If it has broken the top rings you would normally expect an easily felt big lip at the top of the bore, if the block has been checked and there isn't a lip it may have been down to clumsy fitting of the pistons when it was last built.

#10

Posted 22 August 2015 - 09:44 AM

62S makes a good point, were the rings broken up into small sections, or just 2 or 3 pieces?

Using 'ring gap' method of checking for bore wear you are looking for differences.

- if you get gaps of 15, 16, 15, 16 going down bore in 1 inch steps then difference is 0,1,0,1 and it's good!

- if you get gaps of 15, 18,17, 16 going down bore in 1 inch steps then difference is 0,3, 2,1 is probably OK

- if you get gaps of 15, 21, 20, 17 going down bore in 1 inch steps then difference is 0,6 ,5, 2 is wear

Remember this gap method is measuring relative difference in bore circumference, so you need to then divide by 3 to get idea of bore wear on diameter. In the above last example the bore wear would be 6/3 = about 2 thou.

#11

Posted 22 August 2015 - 10:43 AM

#12

Posted 22 August 2015 - 12:06 PM

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users