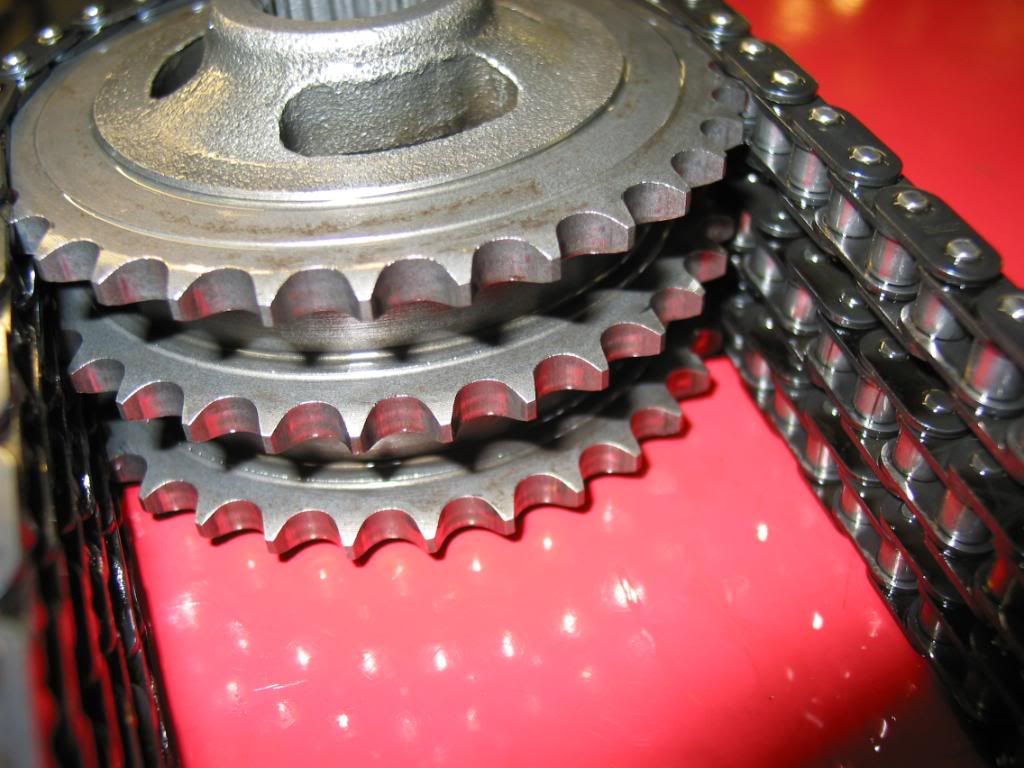

Oh, and if chain drive has been done successfully, which I never knew, but am not really surprised about, why do our spares suppliers not realise that it is a good thing and sell conversion kits? Lack of imagination, perhaps? It certainly needs more engineering design skill than some of the amateurish products which they supply. And, it is very likely to be cheaper than herringbone gears. The geometry of a sprocket for a roller chain is wuite simple and easily machined. You can also change the gear ratio without using the bodged tooth geometry needed to make those dreadful drop gear sets with non-unity ratio. The problem is that the crankshaft and gearbox input shaft centres are where they are, and can't be moved, chain comes in fixed pitches, it is not a good idea to need a tensioning idler if it can be avoided, so to make it all fit, there are constraints on the gear diameter and therefore the number of teeth.

I suspect that the original reason for doing it was to reduce power loss and so get better performance, the elimination of the idler gear problems would have just been a useful side effect. The chain is going to be more efficient than any of the alternatives.

The question of the gearbox casing stress was a good one. Going from tension to compression in the alloy casing could have resulted in buckling, especially of the thin transfer case. However it tolerates the horrid, oblique loading of the idler without complaining, so it is not entirely surprising that it is ok with a chain drive, although such problems do always need to be considered carefully.

The best way forward from the engineering perspective would be to find out exactly how the chain conversion was done. I think the final solution may already have been developed.