So this has been a fun project of mine which has been an idea for quite a long time.

I've become known as a bit of a GKN wheel enthusiast, and am lucky to own a few. But one thing I’ve found even harder to find than the wheels is original wheel nuts.

When I purchased my GT it sat on a set of GKN Silverstone wheels (main reason I bought the car!) it did come with 15 correct wheel nuts, and one dodgy one.

As I intended on having the full set refurbished, I also wanted to do something about the nuts. The originals are certainly presentable, but the chrome is flaking and they wouldn't look right on a perfect set of wheels. I also wanted the option of being able to fit a second set of wheels. To a different car.

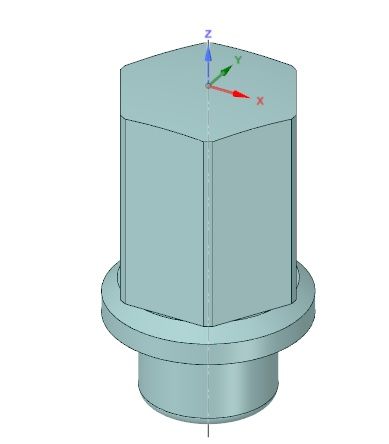

The nuts a very unique shape, with a sleeved design and a very large hex. I know the easiest way of getting around this issue is to just use a secondary sleeve on a more available wheel nut. But this didn't really sit right with me, and they never “look” right.

I’d had this idea for quite a while and a few people had talked about using a manual lathe to make up a set, but this ultimately didn’t come to anything .But a new job presented me with access to some pretty cutting edge tech. My day to day job was doing similar, if not much more complicated reverse engineering tasks for customers. So the idea got revived.

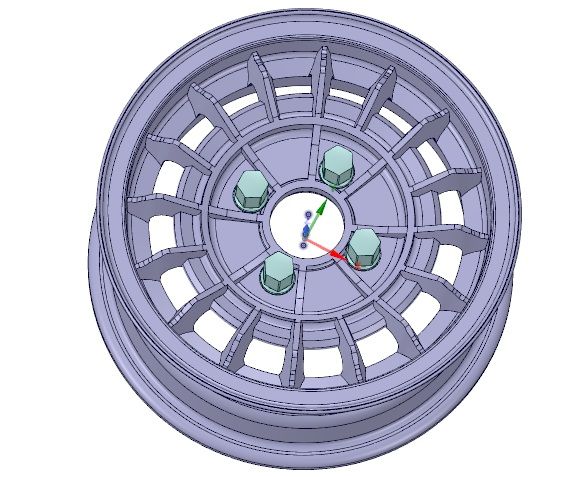

I'd been in the process of producing a CAD model of the wheels in my spare time so drawing up the nuts wasn't too much of a stretch.

This was accompanied with engineering drawings so they could be CNC lathed.

The conception and drawings where relatively simple and the correct sized Hex Bar was sourced. Amazing how easily large imperial Hex bar can be found still! The decision was to go for Stainless Steel so that I could polish it rather than mild steel and have it chromed.

This was mainly for ease of manufacture, and too keep the costs down.

This just left the simple task of the programming and manufacturer.

This was handled by the very capable machine shop at DSN Classics. As this was being done as a personal project it did get bumped down the machine list a little! Eventually it did make it onto the machining list and I received these lovely pictures.

This is just post machining. The nuts are also custom CNC'd to suit the nuts.

The sizing was spot on, so the rest of the bar was cut up too!

A few weeks ago I then made the journey back to Norfolk to collect the finished article.

There are 3 are sets there, and a few more spares as well.

I then tried them for size in my refurbished wheels (I've had them sitting for nearly 3 years)

The proof is in the pudding though!

It was finally time for them to go on the car.

Look at those reflections!

I was very happy how these turned out, definitely worth the time and expense!

This also means my Green GT can go back on its original wheels which makes me very happy.

Joe