I was just reading up on the microsquirt.

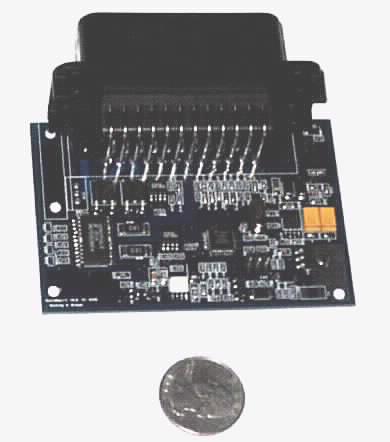

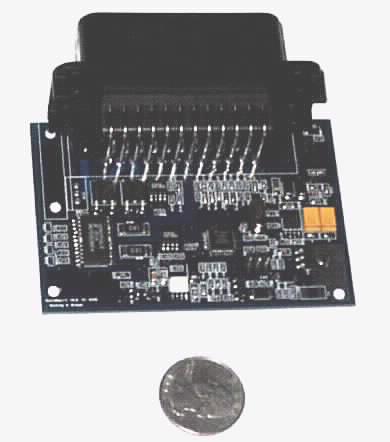

It is supposed to offer all the megasquirt has but in a smaller footprint.(like a credit card)

The only thing left off is the MAP sensor is now external like the GM system.

Microsquirt info

These new units could really open up the market!!

has anyone heard of megajolt?? if you're running the gm fuel injection system then you could just use megajolt to run the spark side of things!! plus if u want some 36-1 pickups for an a-series have a look at this

http://www.mini-pulleys.com/

or for megajolt start reading on the link below!!

http://picasso.org/mjlj/

I was just wondering if I could machine notches in the harmonic balancer and have it work!

I wonder if he does 6 vice 36? Thanks for the link.

I think megajolt would be a huge step backwards.

The GM and the megasquirt both control fuel and timing.

To slave another controller in just to do timing would be uneeded.

I think the whole reason for megajolt is to have timing control with a carb.

Also the GM DIS is already designed as a bypass system so it should be pretty much a plug and play unit once I get the timing wheel made and mounted.

I'm thinking I will start with a wheel attached to the back of the balancer, then when it works I can take my spare and just notch it. Or buy one if his are reasonable.

Edited by Bill USN-1, 15 October 2006 - 01:29 PM.