Nope, thats a Verto flywheel.

Cluch sliping, when striped down needed no puller?????

Started by

marksmini

, Dec 14 2006 11:00 AM

21 replies to this topic

#16

Posted 14 December 2006 - 05:16 PM

#17

Posted 14 December 2006 - 05:44 PM

so if its verto, does it go onto a taperd shaft?

#18

Posted 14 December 2006 - 05:55 PM

Yup, the shaft on the crank is still tapered, the verto clutch and diaphragm clutch are interchangeable (as far as the end of the shaft is concerned).

To be honest though, I've never worked on a verto setup (not that I can remember anyway).

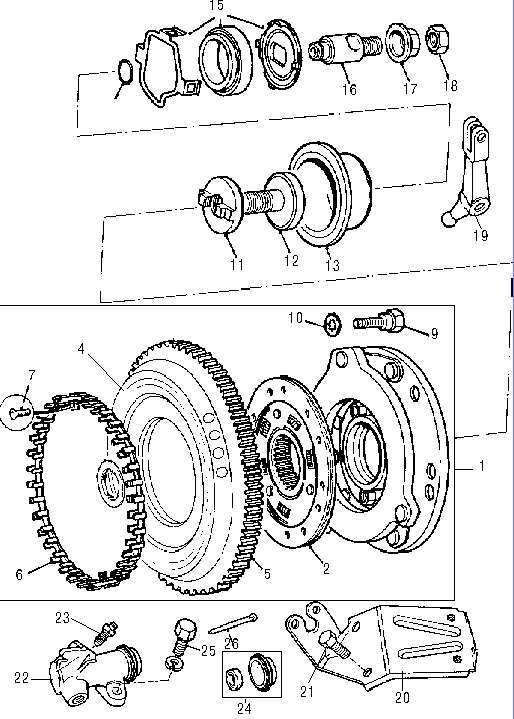

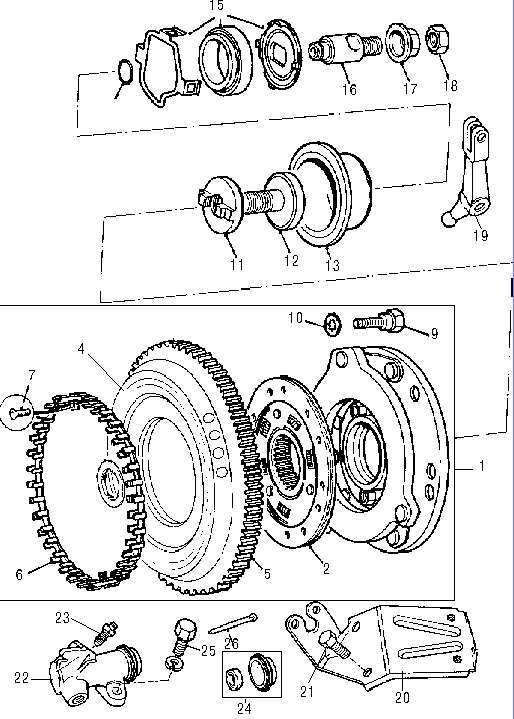

This is how the setup works:

Sometimes, you do get flywheels that come off easier than others. If the whole assembly was loose, you'd notice more than a slipping clutch. I think that perhaps there is a little wear on the pressure plate, the clutch plate and maybe the surface of the flywheel, which all adds up to a slipping clutch scenario????

To be honest though, I've never worked on a verto setup (not that I can remember anyway).

This is how the setup works:

Sometimes, you do get flywheels that come off easier than others. If the whole assembly was loose, you'd notice more than a slipping clutch. I think that perhaps there is a little wear on the pressure plate, the clutch plate and maybe the surface of the flywheel, which all adds up to a slipping clutch scenario????

#19

Posted 14 December 2006 - 06:02 PM

Actually, you could always measure the thickness of the plate and compare it to a new one?

#20

Posted 16 December 2006 - 07:00 PM

IM BACK!

ok been doing some measuring to things to see whats what.

First off on the shaft i measured the far point of the shaft it read below, (MM)

i then measured the point of the pressure plate that sites on the shaft, slightly smaller reading, so thats good i would say time its is pressed on tight,

measured the shaft again but the put closest to the out side, see below (note i moved when take the pic so take 0.4 or 0.5 off that reading oops

then done the same again but on the pressure plate. i found the readings on the pressure plate lower than the shaft? should it not be the same size?

im hoping this has proven the pressure plate will need replacing and with this the new plate should fit on tightly?

i crossed referenced my readings of the shaft with another 998 i had in the garage, the readings can out the same so the crank shaft is ok.

but what is your input, have i read this wrong or d you think my findings are ok?

ok been doing some measuring to things to see whats what.

First off on the shaft i measured the far point of the shaft it read below, (MM)

i then measured the point of the pressure plate that sites on the shaft, slightly smaller reading, so thats good i would say time its is pressed on tight,

measured the shaft again but the put closest to the out side, see below (note i moved when take the pic so take 0.4 or 0.5 off that reading oops

then done the same again but on the pressure plate. i found the readings on the pressure plate lower than the shaft? should it not be the same size?

im hoping this has proven the pressure plate will need replacing and with this the new plate should fit on tightly?

i crossed referenced my readings of the shaft with another 998 i had in the garage, the readings can out the same so the crank shaft is ok.

but what is your input, have i read this wrong or d you think my findings are ok?

#21

Posted 16 December 2006 - 08:15 PM

have you tried a test fit to see if the flywheel sits proud???

#22

Posted 17 December 2006 - 12:33 PM

no good idea. will have a look at that later on today if i get time.

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users