Sill/arch trim

#1

Posted 07 March 2007 - 12:12 PM

I thought about putting the trim in a bucket of hot water, would this help? Any other ideas?

#2

Posted 07 March 2007 - 12:25 PM

leave the trim to soak in hot water before you use it and them if it cools down to much pour some more hot water over it

#3

Posted 07 March 2007 - 12:26 PM

I fitted fluted trim to my cooper just 2 weeks ago, so i can say i am now an expert on the best way to fit it!!

I asssume you are having trouble with the tight bends near the sill??

Forget the hairdryer, its a waste of time! The best way is to pour hot water into a large platic basin near the car, and while holding the trim either side of where the bend is to be made (your hands will be approx 6 inches apart while holding the trim) immerse it in the water. It only takes a couple of seconds to bend, but be careful not to kink it. You will only careful if you are totally careless.

What I did before I dipped it in the water, as to mark with a black pen on the underside in 2 places, where to put the bend.

After the bend is made, what I did with the trim is use a Dremel drill with a cutting disc, and remove the flange on the plastic trim (The bit u cant see) only in the area of the tight bend. This allowed the trim to fit on very easily.

Hope this helps. PM me if u want I will give u my number if u wish

John

#4

Posted 07 March 2007 - 12:38 PM

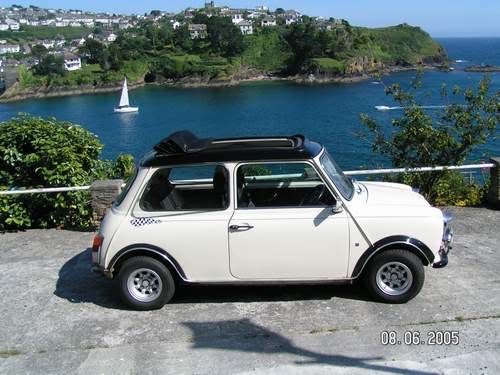

Your car looks a treat by the way John!

#5

Posted 07 March 2007 - 01:27 PM

For the waxoyl, i poured some into a mug, left it for a few days till it became gooey before applying. if u r planning to do the trim at the weekend, good idea this evening to pour half a cup of waxoyl, let it stand. by saturday it will be thick and gooey enough to brush on tso it is effective.

Thanks for the compliment on my mini!

John

#6

Posted 07 March 2007 - 03:12 PM

Thats no problem, the first time I tried I knew the hairdryer was a waste of time! You may find that adding a few holes in the flanges. esp near where the tight bend is a good idea. R/C obby shops sell really small self tap stainless screws which you can cut to length to secure the trim. As long as you blob paint into the hole, let it semi-dry. As you are applying the trim, great idea brush waxoyl over the holes, to minimise corrosion.

I've already painted waxoyl on the lip...I put the stuff anywhere and everywhere that it isn't very visible! I have some pretty small stainless screws but they are around 7mm long...I was thinking of using some clips like the ones which hold the seam strips on, but I am not 100% sure if these are up to the job. I might try one or two and see what I think about those, and if not go the screw route. Thanks again!

#7

Posted 07 March 2007 - 05:08 PM

#8

Posted 07 March 2007 - 06:50 PM

#9

Posted 07 March 2007 - 07:49 PM

when starting it off, go against the natural curve so when you get to the end of the arch were it is above the sill the natural curve will go on without kinking it, in the factory on earlier models the arch trim was pop rivetted on.

#10

Posted 07 March 2007 - 09:52 PM

But you may find that all your flanges are very good, and may not need to screw at all. Just see how it goes, put in screws only if you have to. Obviously, the fewer holes the better.

I personally would steer clear of using silicon, as even if it is put on locally in some areas, it could actually trap small amounts of moisture which wont help your cause. For corrosion resistance, Waxoyl is your best choice in my opinion.

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users