Spent a few hours today working out what to do. I managed to get the rear subframe front mount pins out, along with the old bushes. The bushes are about half as thick round the rim and twice as flexible as the new ones.

I reassembled with the new pins and tightened it all up. It looked like it was going to fit between the mount holes and so I ran long bolts down the captive nuts and used a combination of hammer and crowbar from behind between inner and outer sills to make the axis of the captive nut orthogonal to the heelboard.

Then, with a bit of persuasion, it dropped into place. I had to use the tiny bottle jack to push the front of the floor outwards to achieve a consistent gap between the top of the door frame and the sill line.

I fitted a few tech-screws around, and then thought about how to check for squareness. I used some picture wire between the front subframe bolt holes and the rear corners of the rear subframe:

20190126_150556 by Mike Jackson, on Flickr

20190126_150556 by Mike Jackson, on Flickr

20190126_150352 by Mike Jackson, on Flickr

20190126_150352 by Mike Jackson, on Flickr

20190126_150250 by Mike Jackson, on Flickr

20190126_150250 by Mike Jackson, on Flickr

Seems to be bang-on square:

20190126_150309 by Mike Jackson, on Flickr

20190126_150309 by Mike Jackson, on Flickr

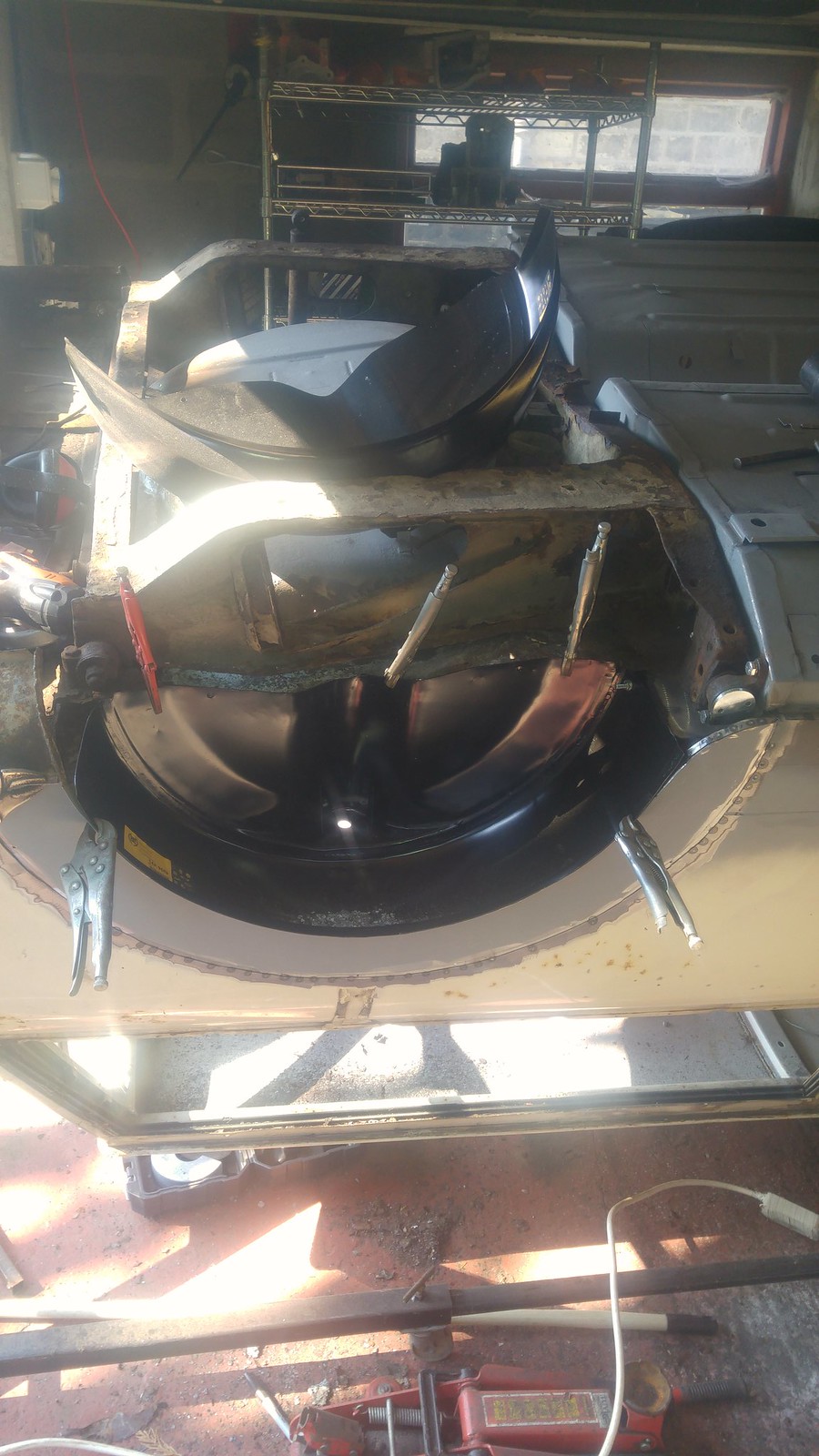

Replaced the various mole-grips along the sides with tech-screws:

20190126_151943 by Mike Jackson, on Flickr

20190126_151943 by Mike Jackson, on Flickr

Then hoisted the front subframe off, again, and drilled some holes for plug-welding the toe board:

20190126_160047 by Mike Jackson, on Flickr

20190126_160047 by Mike Jackson, on Flickr

I've used welding clamps to pull the boot floor repairs I made to the heelboard, they all line up nice but I forgot to take a pic.

I'll spin the shell over next and see if I can sort out the warps on the inner sills.