'mini Blade'

#91

Posted 07 March 2010 - 06:00 PM

#92

Posted 07 March 2010 - 11:08 PM

latest updates, inner wheel arch covers removed and rear end cut out tidy'd. also started playing with some 1" copper pipe bending and soldering it to mimic the frame as a sort of practice run before the steel. The steel has arrived and hydraulic bender is ready and waiting

#93

Posted 19 March 2010 - 02:55 AM

the rear end of the mini is pretty well cut out now, just needs the edges tidying etc and to cut the floor back more accurately when the dimensions are finally worked out.

the frame has been started and so far have most of what would be a four point frame. lots left to do but this is how it is going so far. and before anyone starts, the welds are just tacks in place.

4440886629_2265644900_b_2_.jpg 56.34K

36 downloads

4440886629_2265644900_b_2_.jpg 56.34K

36 downloads 4440896769_fc53ed1212_b_2_.jpg 54.69K

36 downloads

4440896769_fc53ed1212_b_2_.jpg 54.69K

36 downloads 4442883603_f8e74226d2_b_2_.jpg 53.06K

32 downloads

4442883603_f8e74226d2_b_2_.jpg 53.06K

32 downloadsyou may notice at the back of the mini i have took a bar straight across with no indent like the typical zcars frame, this is to keep maximum strength and does not need to be there. My mate is making a custom manifold for me so that i dont need to take the conventional exhaust route and can have it running wherever i want. He also has some nice ideas of manifold layouts to maximise performance which should be very interesting.

i have just brought some brakes off ebay, some mk3 golf gti rear brakes, going to get hold of some mk2 disks and mk3 handbrake cables and modify etc etc etc.

working on a chain adjuster setup to, which instead of rocking the modified diff setup back an forth off the engine like zcars method, it will act more like a chain adjuster bar pushin in or out against the chain to the required tension as i feel this will work better and wont require so many components to move, similar principle to this....

Adjuster.jpg 37.53K

93 downloads

Adjuster.jpg 37.53K

93 downloadslots going on at the mo and slowly coming together

p.s does anyone know of anyone selling any cheap bucket seats, preferably black or red or both lol ?

Cheers guys

#94

Posted 13 May 2010 - 11:43 AM

#95

Posted 16 May 2010 - 08:36 AM

Edited by Sean12, 16 May 2010 - 08:37 AM.

#96

Posted 22 July 2010 - 03:37 PM

#97

Posted 23 July 2010 - 01:10 AM

Have done a bit more work though so will put up a small update, now that i am back at work i will have some more money to throw at the project which will be nice. Also took my self out a loan in the aim of buying myself a (new shape) Mini Cooper S with JCW kit

So anyway the update, basically just been doing more work on creating the space frame and fitting two new floor pans. as you can see from my last update i had started work on the uprights and the general shape of the frame within the shell. from here we created the brackets to bolt the space frame to the mini monocoque. i opted to create plates for inside and outside the shell for extra strength. once these brackets were created, they were just tacked in place to the space frame to hold each side in place. They appeared to be very strong even only being tacked. The reason for the wierd bolt arrangement was to ensure that the floor bar would meet nicely to the upright and you would not have an akward, if not impossible, job of trying to bolt it in place when welded. once the brackets had been made and tacked onto the frame, the floor bar was then adjusted to suit and the cut and coped to ensure it joined the upright smoothly, ensuring that the centrelines of the tubes intersected as best as possible. From here i went about making a roof bar in a similar manor, and eventually cutting and coping this to suit. It doesnt look like a fat load of work but some of it is a bugger to work out and make, spesh for a first timer and not a professional fabricator.

I am please with how it is looking at the moment an hopefully it will start to move along a little quicker now, well ive been temporarily distracted fitting webbers to my brothers at the mo to so will juggle them both as mine is my main concern...naturally lol

brought some other goodies to... Bucket Seats, Dash (Thanks to jason at Mini show Cannonhill), hubs, disks.....

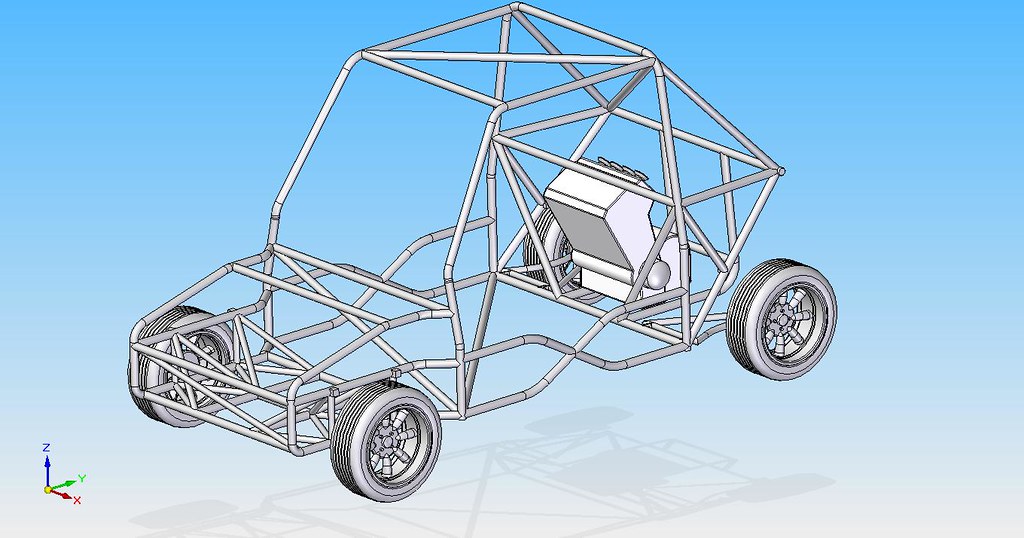

i have also attached a quick little 3d model i was playing around with and the type of concept i was tryin to create.

next steps for the project.... Finish the cockpit area of the frame, level up the mini and create frame to support engine. Get the mini sand/media/soda blasted. Keep buying parts and steel tubing lol

pics to follow, and sorry for the lengthy time inbetween updates but cheers for still showing interest !!!

#98

Posted 24 July 2010 - 12:26 PM

#99

Posted 24 July 2010 - 03:30 PM

how are you doing your diff housing? are you doing it or getting it made ? get a thread going an get some pics up !!

#100

Posted 24 July 2010 - 07:58 PM

#101

Posted 24 July 2010 - 08:09 PM

well to be honest not a fat lot at first, just concentrating on getting the thing in first. I will probably invest in a barnett clutch, and once mini is running and road worthy (passed IVA) i have plans to turbo it so we will see what happens

#102

Posted 02 August 2010 - 07:40 PM

Edited by Sean12, 02 August 2010 - 11:25 PM.

#103

Posted 04 August 2010 - 09:36 PM

anyone know of any decent suspension at resonable prices ? i have seen some gaz coilovers at rally design for a good price, just wondering if anyone knew of any other places to look at/experienced ?!?!

one of the lads whos done a zcars build for hill climbing has changed to bike shocks, might be worth looking into and talking to him about his experiences and why he done it.

#104

Posted 05 August 2010 - 07:23 AM

#105

Posted 06 August 2010 - 09:05 AM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users