Temp/fuel Gauge On A Later Nippon S Gauge Set

#1

Posted 28 December 2009 - 06:24 PM

now before i buy a replacement 2 clock cluster and add on the tacho from my existing one id like to ask a couple of questions

is the voltage regulator built into the tacho? (sounds stupid if it is seing as not all minis had the tacho) because after mismantling the gauges all i found was the cogs etc for the speedo and the wire elements for the fuel/temp gauges

iv been told if the gauges are at fault theres nothing that can be done to fix em hence why im ready to buy a replacements

before i buy it..i just want to run through the checks iv already made..shorting the sensor ends causes both gauges to read as full/Hot.

out of the multiplug is there a wire to check the voltage of for the gauges incase the problem is external....but if the regulator is built into the clocks even though i cannot find it, i would have guesses it to be 12V on the multiplug end?

...what else could be at fault?

#2

Posted 28 December 2009 - 07:08 PM

#3

Posted 28 December 2009 - 07:49 PM

#4

Posted 29 December 2009 - 02:43 AM

Stormintrooper, according to Taffy, some of the early NS gauge clusters still used an external voltage stabilizer. However, I've only seen pictures of the insides of what must be the later type which (as Dan said) have the stabilizer built into one of the gauges.

You are correct that the gauges work by the heating of a bimetallic element wound with resistance wire. However, in the pictures I mentioned above, on one of the gauges there was clearly a second bimetallic element wrapped with resistance wire... and terminated on one end by a set of contact points. Basically it was a open-frame version of the Smiths stabilizer.

On another recent thread I suggested something that I will likely never have the resources to try... but you might be able to.... Jupitus was selling the solid state stabilizer chips. I can envision a very careful dissection of the later NS gauge cluster and wiring in the solid state chip in place of the NS stabilizer. It shouldn't be too hard if you're comfortable taking the gauge cluster apart.

#5

Posted 29 December 2009 - 06:31 PM

hmm....i can't say for certain as i dnt remember fully but as memory serves i have only ever found two of the bimetallic elemtns..one for each needle..might this sugest i have a stabiliser located elsewhere?

if so where am i likely to find it?

#6

Posted 29 December 2009 - 06:54 PM

EDIT: I found what I mentioned above. Trooper, take a look at this old thread, specifically page 2.

http://www.theminifo...x...ippon&st=15

Scroll down to the SECOND set of pictures posted by garrett3. The top picture in his second set shows ONE of the NS gauges. In that picture you will notice that the gauge has TWO bimetallic fingers wrapped with resistance heating wire. The TOP finger/windings has a set of points on the "right" end. (Look below the brass nut with the red varnish on it). Those points open and close and are the equivalent of the Smiths stabilizer.

(Here's a direct link to garrett3's picture)

http://i54.photobuck...kstrip010-1.jpg

Garrett3 suggested or said that these gauges were from an SPI so your gauges may be different. Taffy should be able to tell you.

#7

Posted 29 December 2009 - 07:22 PM

#8

Posted 03 January 2010 - 06:37 PM

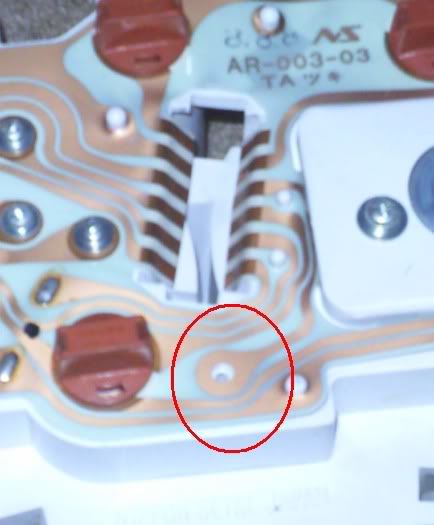

thats my fuel gauge needle set up

also found part of the printed circuit that makes no sense to me

#9

Posted 03 January 2010 - 09:11 PM

#10

Posted 03 January 2010 - 11:51 PM

#11

Posted 03 January 2010 - 11:57 PM

is it to do with the little brass nut?

Edited by stormintrooper, 04 January 2010 - 12:06 AM.

#12

Posted 04 January 2010 - 12:05 AM

#13

Posted 04 January 2010 - 12:15 AM

#14

Posted 04 January 2010 - 12:36 AM

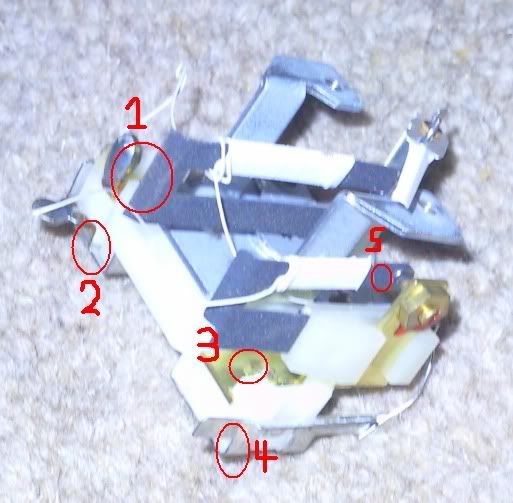

is number 2 the stabiliser input? and does it matter whether i use points 3 or 4 as a ground as both points are joined by wire as far as i could tell?

and is number 5 where i should test the voltage?

#15

Posted 04 January 2010 - 12:49 AM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users