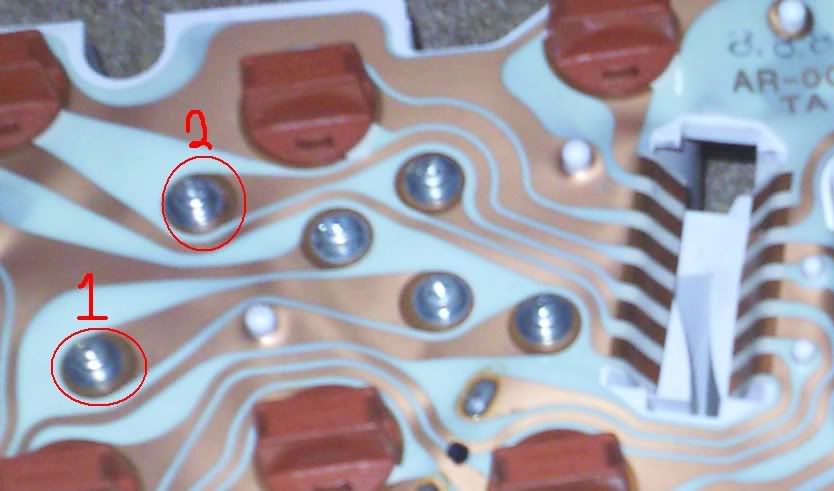

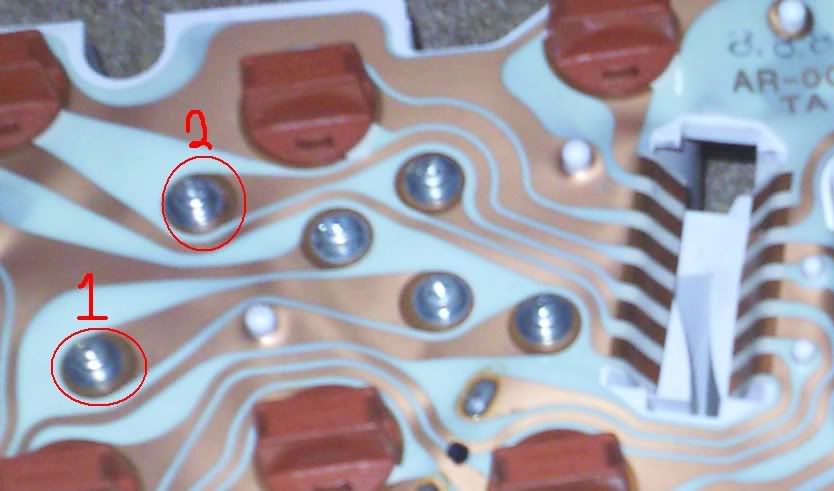

is number 1 where i should put my multimeter because as far as my logic goes number 2 leads towards the temp sender which then goes to ground neway?

Posted 04 January 2010 - 12:59 AM

Posted 04 January 2010 - 01:58 AM

Posted 04 January 2010 - 10:41 AM

Posted 04 January 2010 - 12:58 PM

Posted 04 January 2010 - 02:14 PM

Posted 04 January 2010 - 03:20 PM

Posted 04 January 2010 - 03:44 PM

Edited by stormintrooper, 04 January 2010 - 03:45 PM.

Posted 04 January 2010 - 04:19 PM

Posted 04 January 2010 - 05:02 PM

Posted 04 January 2010 - 05:13 PM

Posted 04 January 2010 - 05:22 PM

Posted 04 January 2010 - 05:28 PM

Posted 05 January 2010 - 12:06 AM

Posted 05 January 2010 - 12:59 AM

Posted 05 January 2010 - 03:30 AM

0 members, 1 guests, 0 anonymous users