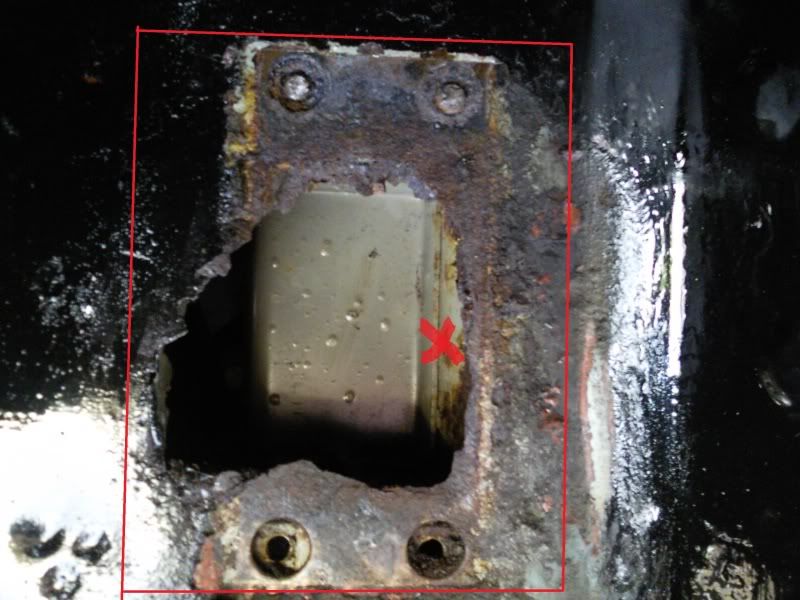

So I've just taken off the mount on each side and theres not alot left of the metal behind them. I've just had a mobile welder come round and He said if I just grind out the rust and cut out a nice square where I want a plate putting he'll come down and weld it in for me.

My first question is the top 2 bolts sheared off instantly under the slightest force when trying to remove them. So the first thing is to get those out - What are peoples suggestions for this?

I have a set of stud extractors AKA 'easy outs' but apart form that what are my other options? I could drill them out - But I dont really want to damage the threads - So could I drill them out without damaging the threads? Because I'm unsure my drill will fit under the wing properly to drill them out squarely...

Also i've drawn on where I plan to cut - Does this look ok? I don't want to cut too far to the right because of the curve that occurs in the inner wing about an inch to the right of the shock mount. I'm hoping I can keep it as a flat patch so I can make it myself to save some money.

Finally the area i've marked with a cross. How can I Stop in the rusting, that won't go up in flames when the guy comes to weld it?

Here a pics of whats left:

Help will be much appreciated as this will be the first proper preparation of this sort i've done...