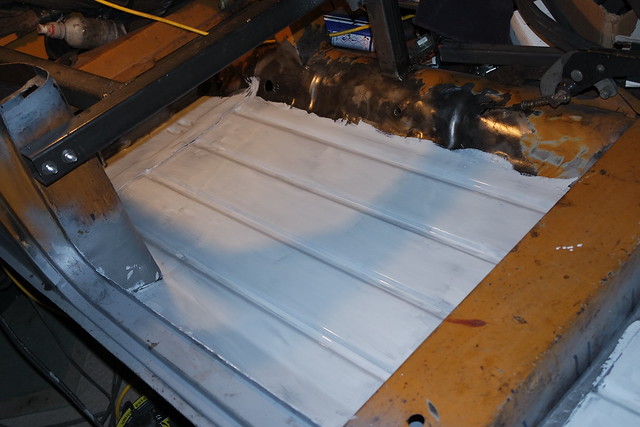

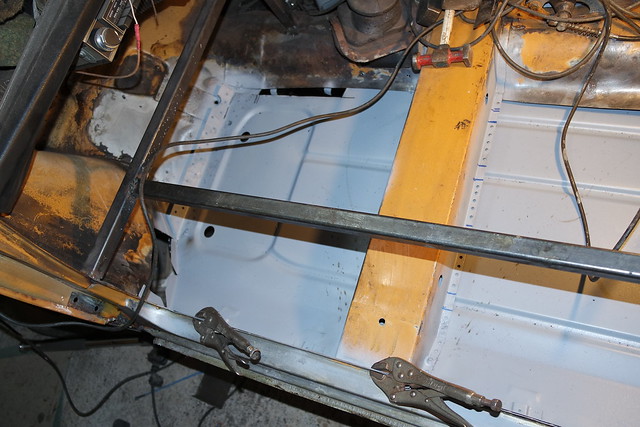

Been finishing off the side I'm working on, cleaning up welding and them little bits that needed doing, like adding a good bit of paint, the silver paint is 2k glass flake epoxy primer(similar stuff used on forth bridge so should be good!) and the white stuff is an epoxy primer from Blakes for metal work on Boats, so this should be more than enough rust protection! but a top coat will be added.

I refitted the battery brackets.

Cleaned floor up ready for painting.

Drilled holes in the headlight bracket and made sure indicator fitted(needed to elongate the holes), then painted them up.

And finally a good lick of paint on the floor panel, just got to clean up underneath and paint that now!