Home Brewed Micra Mini

#46

Posted 27 August 2016 - 08:52 AM

I'll get a photo of mine later.

#47

Posted 29 August 2016 - 08:35 AM

Why didn't you just put a hole the exact size of the unthreaded part of the pin?

I'll get a photo of mine later.

I didnt have the right size cutter, so milled the hole first and turned the pins to match exactly.

#48

Posted 29 August 2016 - 08:37 AM

I couldn't find an MPI tank at a reasonable price so I bought an SPI tank and was hoping to change the pump for the Micra one.

I still can't get my head round having 12v power inside a petrol tank!

I have one for sale. Spi has lower pump pressure

Hi there, just saw this. Complete mpi tank with pump? Sounds good, pm me a pic etc. Cheers.

Edited by micraminiman, 29 August 2016 - 08:40 AM.

#49

Posted 29 August 2016 - 10:31 AM

Busy day in the garage working on my Micra Subframe, welding on the plates I made for mounting the bottom arms, and also trying the complete hub assemblies on to check the fit.

Had to modify one of the subframe arms to clear the tie rod on the drivers side a bit. Not a problem tho and it's all fine now.

Waiting on my adjustable tie rods to arrive next, and then plate up the tie rod mounts at the front and get it tried on the shell again with the engine in it, to line it all up for making the engine mounts.

Attached Files

#50

Posted 29 August 2016 - 02:09 PM

Why didn't you just put a hole the exact size of the unthreaded part of the pin?

I'll get a photo of mine later.I didnt have the right size cutter, so milled the hole first and turned the pins to match exactly.

What I was trying to explain is that you could have made the pin more like a bolt that clamps the bottom arm between the new part you welded in and the rear of the tower (existing hole). This should be much stronger than what I think you have done. Yours looks like the head of the pin is a "loose" fit in the part you welded in?

#51

Posted 29 August 2016 - 02:24 PM

Then it would have been the thickness of the plate too narrow if I used the original pins. I did think about making a whole new pin, or just using a bolt, but where is the fun in that? ![]()

Besides, its now a nice neat flush-fit in the plate with nothing sticking out.

I just made it the same as it was originally and a fit into a hole with a key. I machined the hole to 28mm, and reamed it. The pin was then turned to a nice close tolerance fit and its perfect. Others have done it exactly the same and have had no issues.

Hopefully mine will be the same! lol

#52

Posted 29 August 2016 - 02:50 PM

Should all be good as it is same as original.

#53

Posted 29 August 2016 - 03:05 PM

Hope so! Its all a nice fit on the frame anyway.

Need to get these new tie rods home now so I can finish the front mounts. I decided that the nylon bushes I used to use for the racing are too hard for road use, and have ordered poly bushes for there as well. The joys of being so remote, the waiting time!

#54

Posted 30 August 2016 - 08:23 PM

New adjustable tie rods fitted onto the Mini's subframe, and the frame fitted onto the shell to test it's fit.

The Micra engine went in next to see how it all fits together. Looks nice in its new home, far better than in a Nissan.....

Attached Files

#55

Posted 31 August 2016 - 05:31 PM

Attached Files

#56

Posted 01 September 2016 - 08:31 AM

Where would I buy some bends and pipe to make the exhaust manifold from online?

#57

Posted 01 September 2016 - 09:54 AM

I worked out it was cheaper to modify than to make new.

#58

Posted 01 September 2016 - 11:11 AM

All the K series manifolds I can see are cast lumps. Is there one specific model that is mild steel maybe?

I had planned on making one out of mandrel bent exhaust tubing or similar.

Thanks.

#59

Posted 01 September 2016 - 02:10 PM

I'm not sure which K series one others are using but I do remember they cut the flange off and weld up the join. You might need to search through some other build threads.

Technically just about any tubular manifold that kicks over to the correct side could be made to fit. You need to decide if you want 4-1 or 4-2-1 and have a look through Ebay. I searched for "stainless exhaust manifold" and filtered it down to auctions only. then just sit tight until one comes up at the right price.

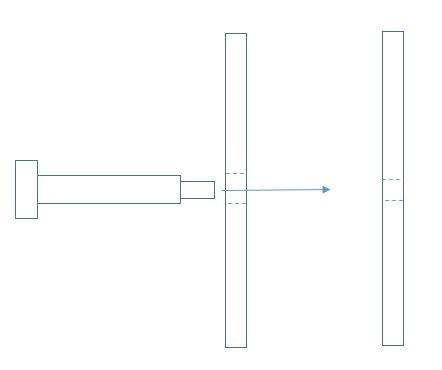

This is roughly what I have bit it still needs final TIG welding after the engine is in.

#60

Posted 01 September 2016 - 02:32 PM

Very nice! Must keep an eye out right enough. Thanks.

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users