Hi all here's pip. I bought her with my heart and not my mind quiet a FEW months back (in February

well like i said bought with my heart and not my mind i set out to get her back on the road.

now she's been staying all over the place recently there was my ex's house

she stayed there for some months and i started to strip her down slowly ready to fix her up and put a 1275 in

so it ended up at my place as the parents were away for a month in june time and i set myself a goal of at least trying to get her road worthy within that time.......

(yer its harder that what i thought..... once again thinking with my heart and not my mind!!)

so here she is in my yard and me and my mate wayne have already dropped the engine within 20mins (note this is where the caravan goes..... and parents wont be too happy when they come home)

so after stripping her i asses the damages....

NOT GOOD!

mess everywhere!

so the weather was good to me over june/beggining july then the storms hit us

action time

works ldv van great for the mini

loads of room

so i gets the car out of the yard and think where can i take it...... i know!! pip's lugged off to my work......

*NOTE* people get permission to bring mini's that you are working on to work.... lets just say they weren't impressed!!

so anyway parents come back and ask me what ive been up to in the yard.....

so i tell them the truth and they weren't happy aswell......

what is it about people!!! anyway back to the build (well moving atm!)

so pips been carried from joneys to my ex's house, then from the ex's to my house, then it's from there to my work, and now! parents say she's allowed to come back home!! yer i was knackered after this! late nites!!

at this point you would have expected your mate that helps you out to turn round and say f**k off aswell but he's a good friend and helped me move the car about

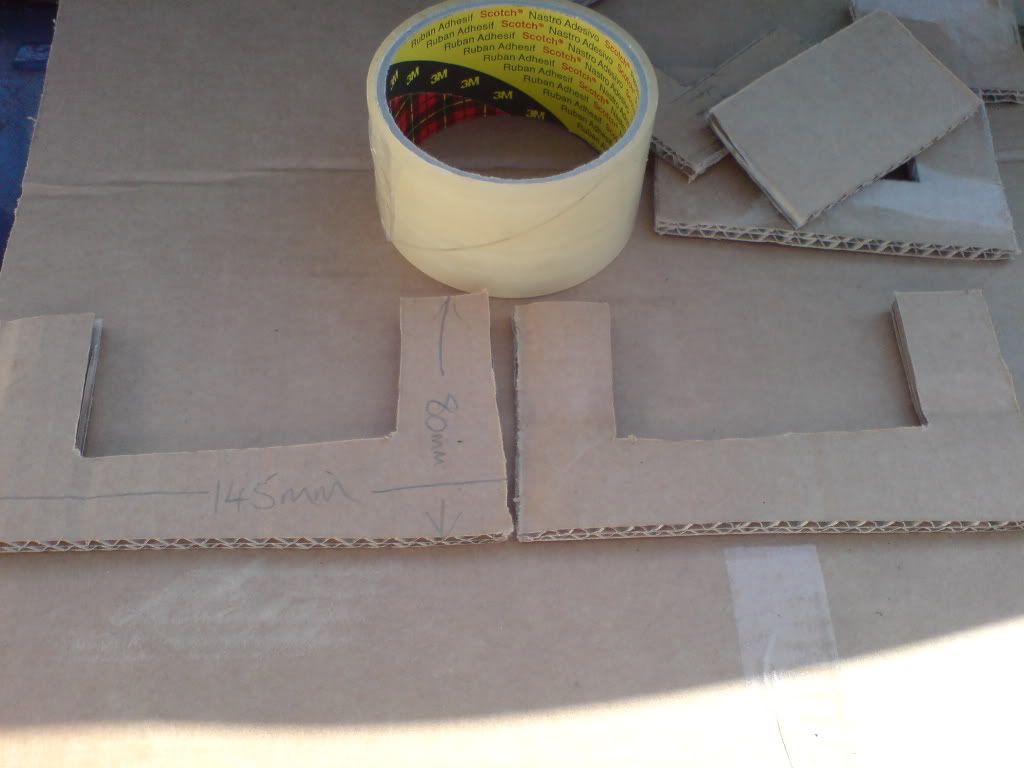

oh while the parents were away i bought a few toys as i foolishly thought i could get the car back on the road so here's my toys for her

to be contd in next post..........

Edited by Daveuk, 09 November 2008 - 09:44 PM.