Red has been a well used Mini especially as Paul likes his Motorsport so he's been used as an Autotester and other little things here and there. It was at an Auto test that brought on the rebuild as he destroyed his diff big time

So we ripped the engine out and he languished in the workshop unloved for a while until Paul set to with the angle grinder to whip off the front of the car and scuttle. He did a few repairs to the inner wing flanges and the top of the bulkhead panel.

Another little hiatus later and Paddy moved into the workshop and once i moved down we then took the bit between the teeth and cracked on with Red.

I fitted a nice new shiny Scuttle

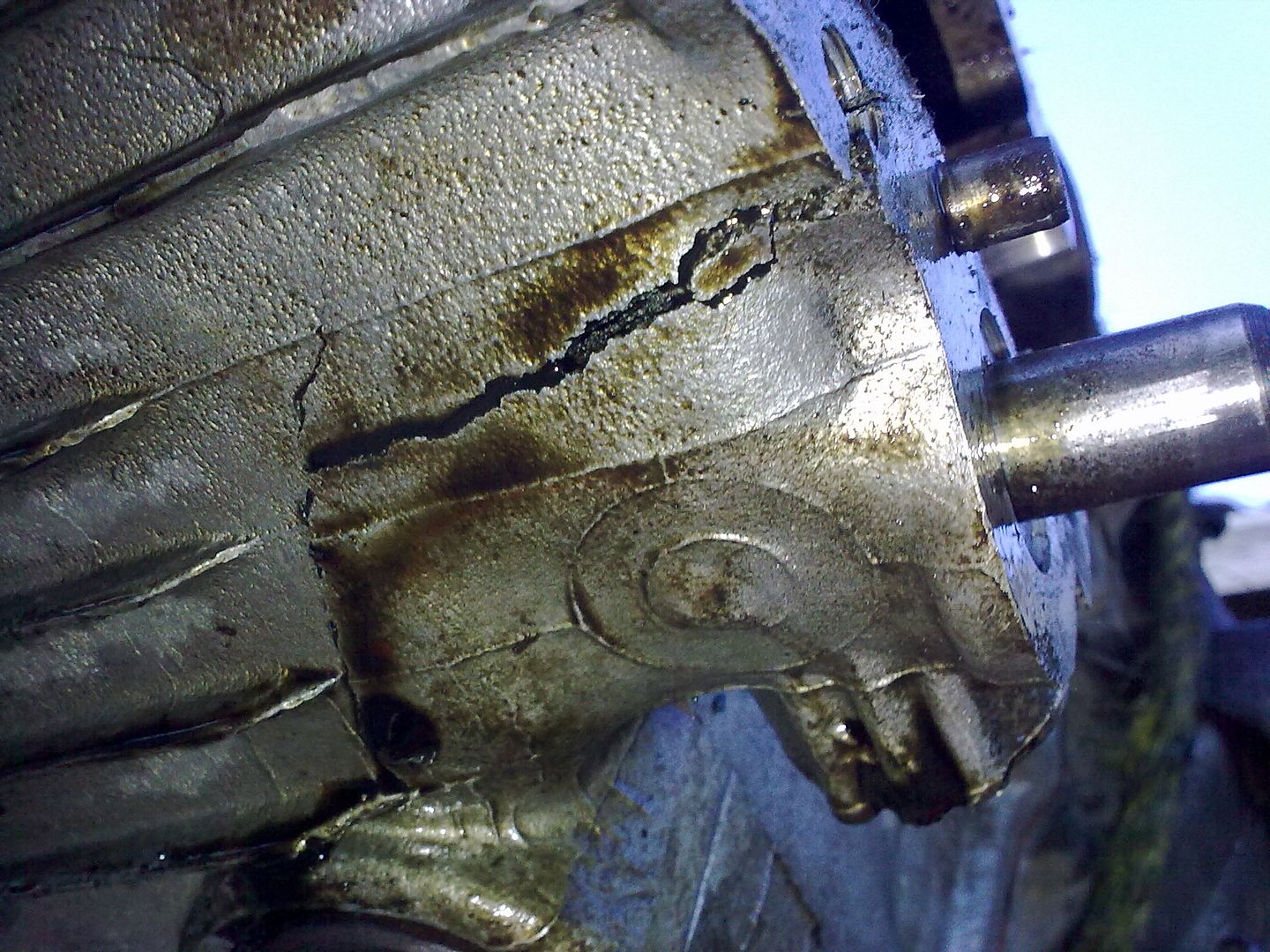

while Paul removed the shock absorber mounts to find this

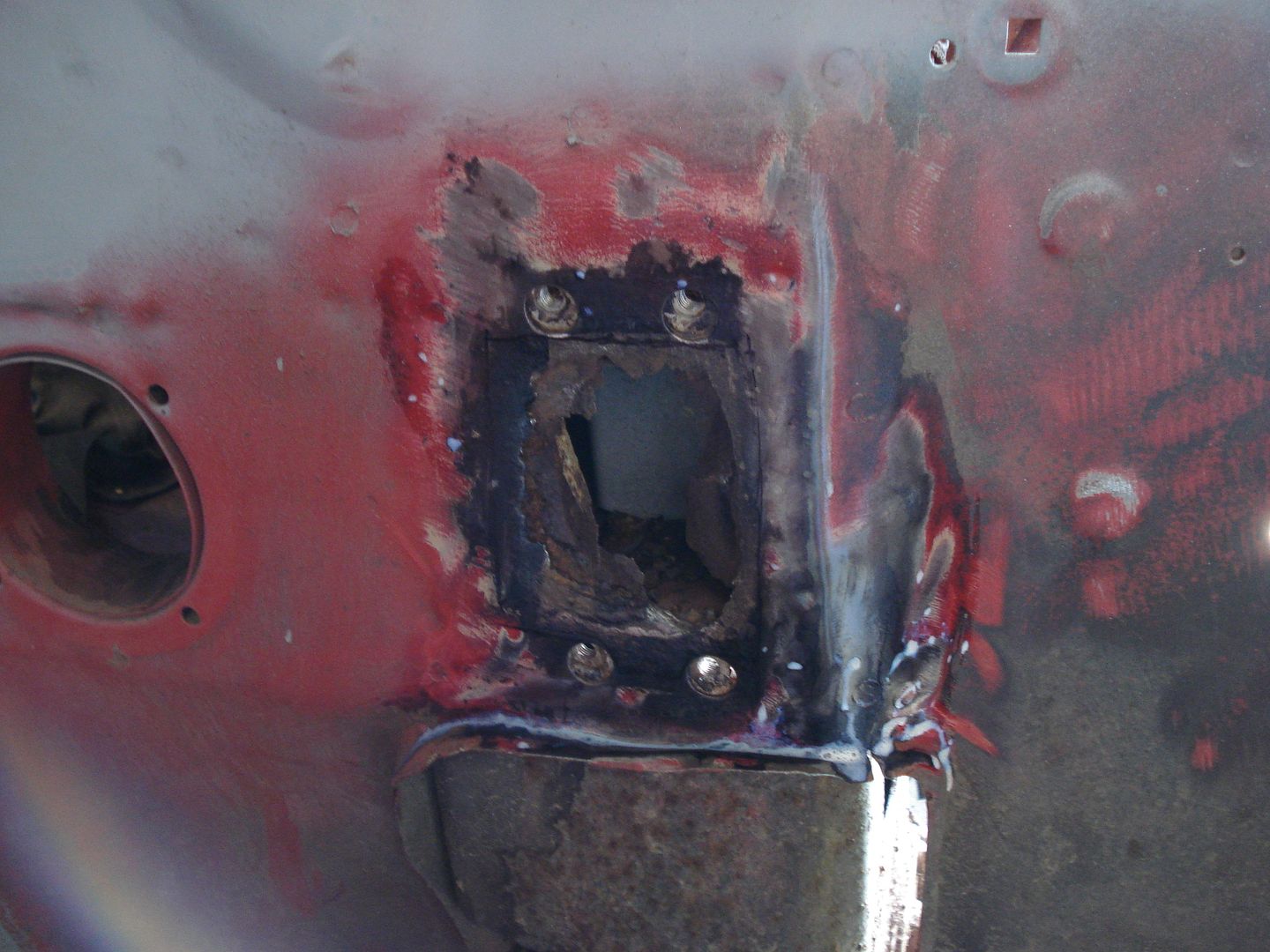

and ended up doing this

We had spent a day at the beginning of the week lining up all of the front panels with the left side coming up nicely but the right just would not go. However its nearly there so hopefully when his wings are back from being media blasted we shall get the right side sorted.

Also there had been so iffy repairs to the floors so the right side i cut out and fabricated a new repair panel for the flitch and am in the process of making one for the floor

The l/h side has to be sorted yet