Scuttle

Started by

xBR4DLEY

, Oct 18 2009 09:04 PM

66 replies to this topic

#61

Posted 19 October 2009 - 07:22 PM

would just like to say that i think he has a great project! and no matter what state it is you are still learning, its not like its gonna be a bodge job to get it on the road any time soon, I recon callum if you put a few good years of hard work into her it will be an ace car!  , i will be watching your progress

, i will be watching your progress

#62

Posted 19 October 2009 - 07:25 PM

Can anyone help me find a genuine full floor panel then I will talk to Dad

Have a look at these

http://www.somerford...x...8&chapter=4

Ideally you'd go for part 2 its a full floor with the crossmember and heelboard.

#63

Posted 19 October 2009 - 11:24 PM

What you must bear in mind is that cars are machines that have to work when they are finished. It's one thing welding it up as a box and getting it all back together but what if after spending all these years repairing and welding the shell, one patch at a time you find that it eats tyres or won't drive in a straight line? Accuracy is important and the floorpan is where a lot of that comes from. Patching up a floorpan like this, especially one that has very little original metal remaining in a car that has been sat in a hedge with no sills fitted for a long time, leaves lots of opertunity for twisting the shell. Each patch you make only needs to be out by a tiny fraction but by the time there are say 20 patches along the length of one side and a new full length floor or just a different set of patches on the other the shell could be quite twisted. 20 patches is a lot but from the look of some of your photos is the kind of number we're talking about. This is where the experience of a body specialist comes into play to decide that a panel is in need of total replacement. A complete new panel will be the right size and shape usually, especially an underside panel like a floor. Wings and things aren't so important but floors and sills definitely are. You should definitely think about using a full floor. It's an expensive panel but will ensure the car is built on a solid base. You also need to start taking precise and critical measurements of this shell, comparing it side to side to see if it's the right shape. You should get some bracing welded into it where you can. When taking on major panel replacements like these, body specialists will temporarily weld lengths of square tube into place along and across the car to stop it twisting while it's in a weakened state.

#64

Posted 20 October 2009 - 09:25 AM

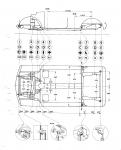

Im pretty sure i have a diagram showing the correct jigging dimesions on my home computer that will help a lot with this car.Il post it up tonight unless someone has one to hand.

#67

Posted 25 October 2009 - 09:49 PM

Dad has decided to a front to back floor panel instead of the two seperate ones

Also will be buying a new A post (door frame) and crossmember (does my car have square or round transmission tunnel)

Also will be buying a new A post (door frame) and crossmember (does my car have square or round transmission tunnel)

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users