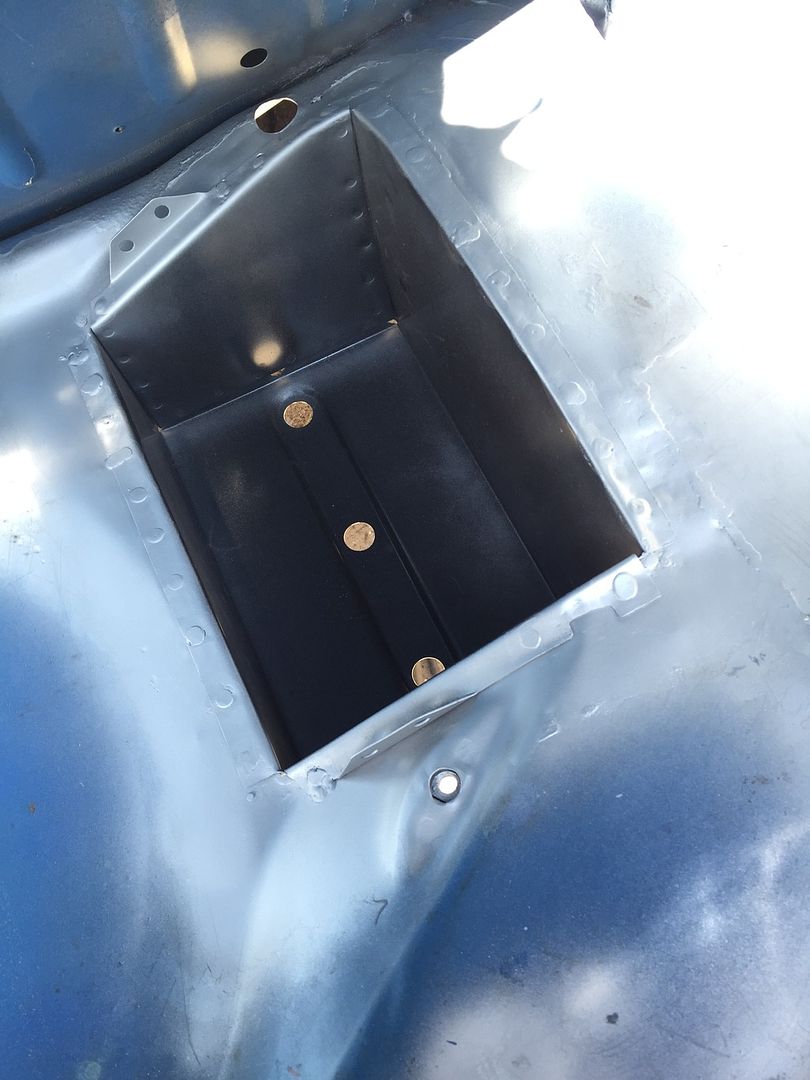

Ive got the other companion bin to do as well got a slightly different approach to this one as I fitted two new ones to the lads car and have learnt from my mistakes

Cheers Mark

Posted 26 July 2014 - 07:43 PM

Posted 20 August 2014 - 07:48 PM

Posted 21 August 2014 - 05:45 AM

Posted 22 August 2014 - 06:42 PM

Posted 31 August 2014 - 09:21 PM

Posted 31 August 2014 - 09:46 PM

Bet Jay is loving going back to the manual work again!

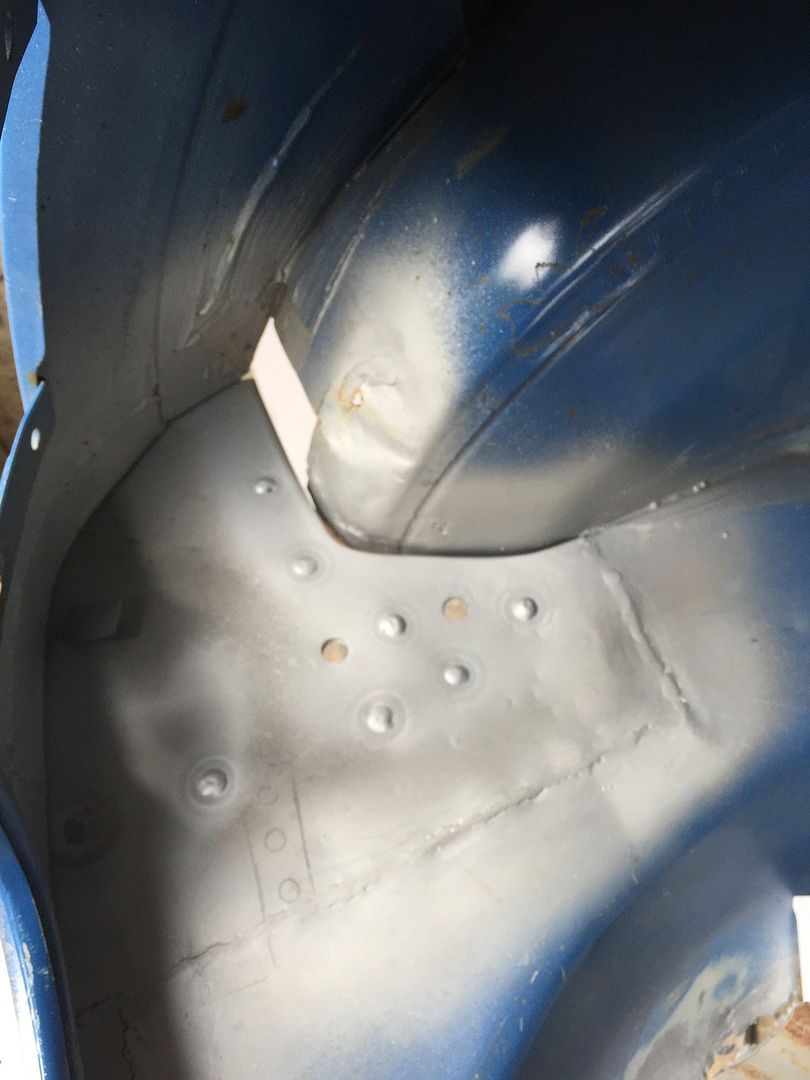

Cracking job on the inner sill. Can you remind me, how much is that panel? I need to order one next week as my project is going to get a massive kick up the backside after all this time. I want to get the O/S done and dusted.

Ben

Posted 01 September 2014 - 06:01 AM

Posted 13 September 2014 - 05:34 PM

Posted 14 September 2014 - 08:00 PM

Posted 11 January 2016 - 08:10 PM

Posted 12 January 2016 - 08:40 AM

Edited by Marco1972, 12 January 2016 - 08:42 AM.

Posted 12 January 2016 - 09:48 AM

Posted 12 January 2016 - 01:47 PM

Posted 12 January 2016 - 02:00 PM

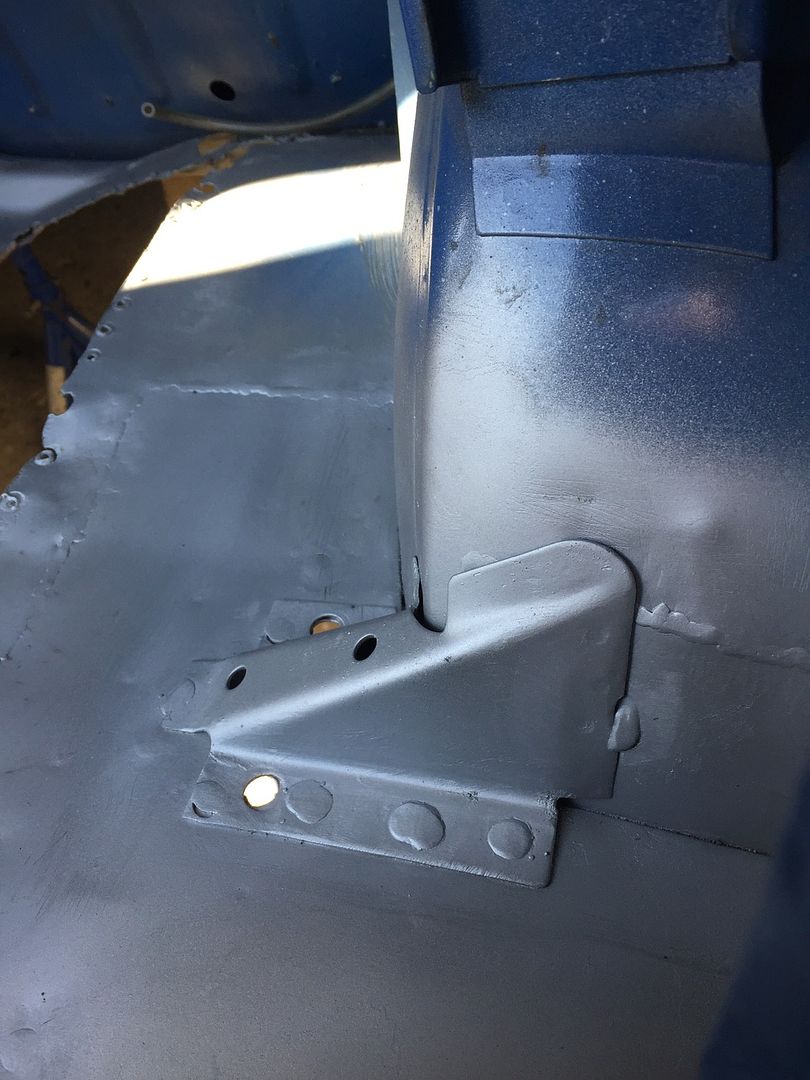

Wow just seen this thread it looks great some really nice tidy work there :)

Posted 12 January 2016 - 07:04 PM

Wow just seen this thread it looks great some really nice tidy work there :)

0 members, 0 guests, 0 anonymous users