Brads 1963 Mk1 850 Mini - Rollcage, 1408, Weber, Rear Beam, Blah Blah

#61

Posted 15 August 2015 - 04:15 AM

#62

Posted 15 August 2015 - 04:27 AM

I'm liking the chalkboard idea!

#63

Posted 15 August 2015 - 02:52 PM

I'm liking the chalkboard idea!

Its so handy! Definitely recommend it. Its good to know that i have somewhere to write jobs and ideas but no shelf space has been compromised

#65

Posted 12 September 2015 - 09:52 AM

On thursday and friday i went to richards workshop and we measured 5000 times and then cut, checked, ground, re-checked, did some more grinding, tacked, checked again, filed and welded. And checked. We ended up with something that resembles a beam.

Not a bad place to work

I brought the old subframe up for extra measurement goodness

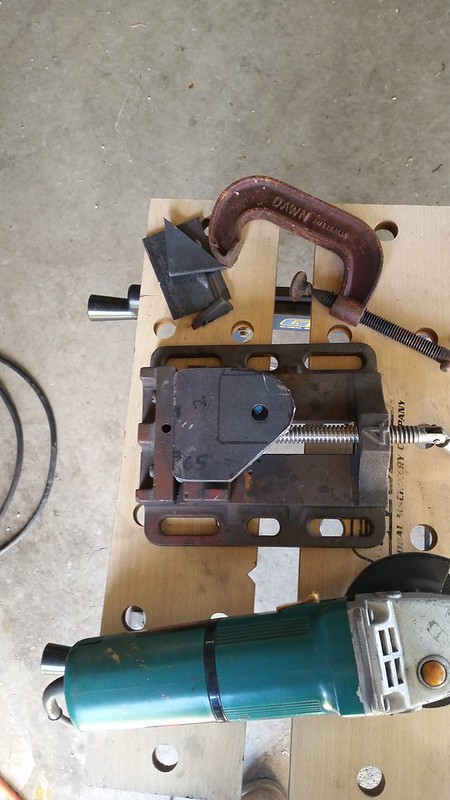

Then the work started. First we determined the trailing arm shaft position in relation to the body and the main two bolts holding the subframe to the body. Then relayed that to the outer angle pieces. We didnt need the full length and area so i trimmed them all up to neaten it

Once we positioned the camber slots, we traced and also got a rough shape of the trailing arm. Then i trimmed

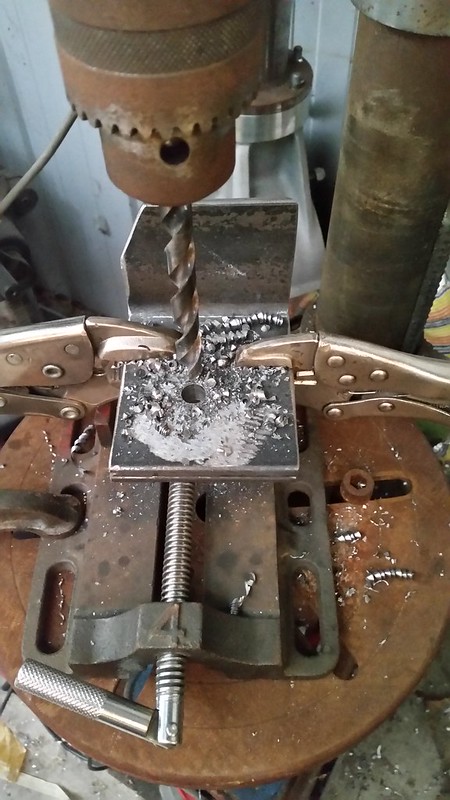

Then came time to weld the plates on. Once on, we drilled and filed the slots out. Nothing like a good old hand file

Once they were done it was time to do the inner angles. The shaft holes were drilled 8mm closer to the beam to allow for our toe adjustment

Once again we made a radius of the trailing arm diametre and neaten the angle up

And the finished inner angle. Holes drilled (carefully after a pilot hole was off centre), trimmed and linished

Then it was time for it to roughly go together. The four mounting holes in the inner angle pieces had to be transferred to the beam. Due to access issues i started by hand drilling (rather than the drill press i used for everything else), but it all worked out well. The beam is now completely drilled

.

.While richard was welding i trimmed some 2x1 channel to use as the rear part of the new subframe. Richo welded my little pre-drilled angles on it later

So its almost done. The beam needs a few slight mods and its complete

#66

Posted 12 December 2016 - 05:37 AM

Edited by braad, 12 December 2016 - 05:40 AM.

#67

Posted 12 December 2016 - 05:46 AM

Onto the next few items, first I sold the mambas a while back without them ever touching the car (two of them weren't removed from their packaging from England - I'm in Australia). In their place, I went (imo) all-out. I contacted the lovely chap Carl from Force Racing about some wheels. Originally planning on buying their 3-piece mamba-style 10x7, I was swayed when Carl mentioned he was making a new mesh style design. So, I ummed and ahhed a bit and decided to throw caution to the wind, buy the wheels without seeing a proper one and go for it. I ordered some 10x7 with black centres and polished inner/outers with equal dimensions (both 3.5"). I enjoyed the fact they were the first set to head out of Europe and only the 3rd set at all, however they haven't been used yet, so the surprise is sort of ruined.

To compliment the wheels, I was looking at getting some Yokohama AO32R's, but another nice bloke from Sydney minis hooked me up with some lovely Dunlop Formula R's. Getting them mounted will be an interesting exercise.

My mate thought it'd be funny to see them up next to his 33" muddies. He was correct, they look ridiculous

With the plan having evolved a while back to go a little nuts, I contacted Protech UK and had a good chat with Kevin (I think) and discussed my plans. He was a lovely bloke who was quite knowledgeable, with the discussion done, they ended up making me a slightly custom set which had a longer body for the rear to enable a bit more droop for road handling. Like the wheels, these were ordered and delivered then put into storage until they are needed.

Front coilover and mounting kit

Rear coilovers, straight (not offset)

This year I have made a few little goals with the mini, one is the boot floor, another the turrets, another the seat mounts. So far I have drawn up the boot and turrets and left it at that, but I have managed to get some mounts made up. These are only the beginnings, as the inner ones interfere with the exhaust tunnel, so will need some chopping and welding. Hopefully I can make some modest progress and get the seats fixed in.

It has been a quiet 12 months since most of the work, but I am hoping that I can slowly nut these little issues out and get the mofo into the next phase in the not-too-distant future. Fingers crossed

Brad

#68

Posted 12 December 2016 - 06:14 AM

ok! All is updated. So the first page has multiple posts hosting the updated story from the beginning to current. Then, as is obvious, I have re-posted the final stuff here as it's 5 pages later.

I'll hopefully keep this thread updated over time and maintain the images a bit better than last time...

Thanks

#69

Posted 12 December 2016 - 07:19 AM

looks like a great build!

#70

Posted 12 December 2016 - 03:27 PM

#71

Posted 18 December 2016 - 11:47 PM

looks like a great build!

Looks a great build. Sorry about your Dad, I'm sure he's enjoying seeing it come together

Thanks for the kind words guys, they're greatly appreciated!

We'll see where I can manage to take it in 2017

#72

Posted 01 September 2017 - 09:50 PM

#73

Posted 18 August 2022 - 12:33 PM

How's the car going braad?

So, I’m quick to reply…

Car hasn’t changed. Life got in the way, then covid. The next few months will determine what happens. So hopefully I’ll have updates of some description soon (relative to the rest of my custodianship)

#74

Posted 16 March 2023 - 05:26 AM

While I’ve tried to keep it stored as dry as possible, I don’t think I imagined it’d only have slight spots of surface rust all these years after being blasted.

Not sure about in the UK, but in Australia I can buy another mini for the price of half decent body work & paint… so that’s what I’ve done! You can see that by clicking on this ——> Morris K van

What does that mean for the 850? Well, I sat down and discussed it with my wife and long story short it will stay and quite likely become a track car in future. The reality is I have a lot of parts to have a track car already (brakes, engine & gearbox, cage, seats, seat mounts, suspension, wheels) and I don’t need to go the whole expensive on-road engineering path.

In the mean time, it will be very slow progress.

The two together

Edited by braad, 16 March 2023 - 05:28 AM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users