Monty the Rwd R1 engined tarmac eating Minus

#361

Posted 28 October 2006 - 09:58 PM

#362

Posted 30 October 2006 - 04:29 PM

#363

Posted 09 December 2006 - 05:16 PM

Don't worry, I haven't fallen off the face of the earth, but I've been very busy. And I've finally got started on the minus again.

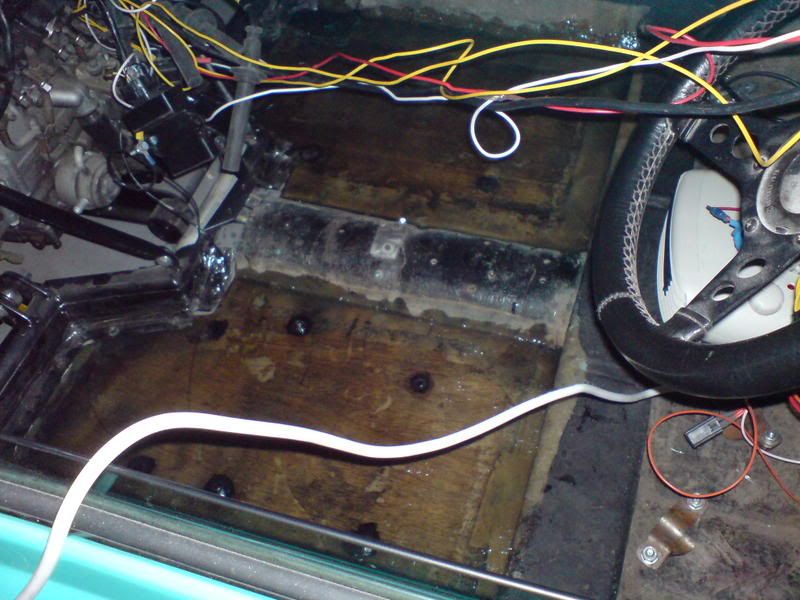

I've not been happy with the floor on the minus, because the ply will now be exposed to the elements:

Soo I've unbolted the rear end and jacked it up and rolled it as far back as possible. I tried to remove the whole cage, but I'm on my todd and It was pretty awkward, so didn't bother:

My uncle made me up some very thin stepped pieces of grp which I've started to prepare. I intend to use loads of poly sealant to fix the pieces in place. Then lay mat and resin over the excess inside the floor and on the outside lip, where the floor has been cut:

Obviously this bit needs a load of material trimming off it, but it gives you an idea of how it will work:

This is it from the inside (i've sanded the floor down to):

#364

Posted 09 December 2006 - 06:36 PM

#365

Posted 08 February 2007 - 05:37 PM

I have cut the mat to shape, but it is too cold for the resin to set properly at the moment. i reckon it needs to be about 10 or 15 degreres before I can start work again. I'm quite frustrated.

Edited by Alburglar, 09 February 2007 - 04:38 AM.

#366

Posted 09 February 2007 - 04:37 AM

#367

Posted 09 February 2007 - 01:13 PM

or Padded tin foil..... any left over can be used for hats

#368

Posted 11 February 2007 - 02:03 AM

tinfoil - LOL

#369

Posted 17 February 2007 - 11:42 PM

Also made up a nice loom with the required resistors in to get the fuel display on the digi dash working. I've left the two stray ends for when I wire it in properly.

I tested it and it now has a real nice transition from empty to full - hooray at last! Many thanks to those who helped with the resistor ratings.

#370

Posted 26 February 2007 - 04:14 PM

So that should be a lot less exposed to the elements

I then put a normal layer of chop strand mat down over the top of the floor pan to cover up the wood, plus I can't hurt to add a bit of strength.

It was bloody awkward doing the stepped edges as there was not much room, but I feel like it was worth the effort.

Edited by Alburglar, 26 February 2007 - 04:16 PM.

#371

Posted 02 March 2007 - 04:05 PM

#372

Posted 02 March 2007 - 05:07 PM

Good to see you got the digi dials working, did you change the resistance at all or just use the value i said (for the fuel gauge)?

#373

Posted 03 March 2007 - 04:36 PM

- much appreciated ed by the way.

...And yes still lots of jobs to do. so here's the check list:

-Fill petrol hole, sand rear half of roof interior and paint the lot.

-bolt cage back in.

-make a dash bar that also steadies the steering coloumn.

- strip back grp and restore all metal in front half of interior, then recover in grp (as i did with rear half).

-remove non ltd slip diff and exchange it for semi- race gripper diff and drive shafts.

-fit hoses (waiting for correct 25mm ones from Z's)

- refit tank

- fit dash and console and fix bloody great holes I put in it!

-fit exhaust manifold

-make a steady structure for rear end (body work wobbles a bit) and hang back box off it too.

-fit throttle position sensor.

-modify pedal and fit throttle cable

- fit gear cable.

-finish fitting brake hoses and rear fit clutch cable then bleed em.

- fit (and buy, come to think of it) sump baffle, change filter and fill put new oil in.

-make and fit bottom half side pieces of bulk head and then fit the whole thing.

-fit expansion tank

-make rear number plate bracket and light.

- fit battery cut off and wire instrument panel and rear lights.

-and final note to self...don't look at this list again as it's depressing. LOL.

Edited by Alburglar, 03 March 2007 - 05:07 PM.

#374

Posted 03 March 2007 - 04:42 PM

whilst doing it I noticecd another bit of fibreglass repair work that needs doing and I also I realised that I haven't filled in the old petrol tank hole yet. Doh!

#375

Posted 08 March 2007 - 11:42 PM

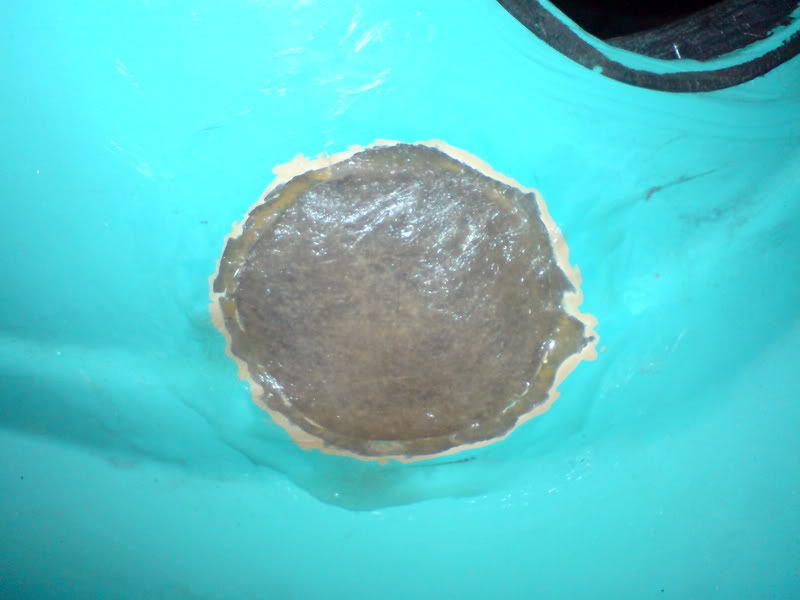

I have dremel'd it back and aplied more grp.

I also filled the old fuel tank hole with grp

Since the photo, I have sanded it to match the swage lines and applied a skim of filler. I'm just waiting for the it to dry before final sanding.

I then filled the old exhaust aperture on the rear valance. I adopted a rather heath robinson aproach but it got the job done.

I had previously cut some holes in the dash for two small electric heaters, this was my first attempt to solve the de-mister problem until I came up with the pipe idea, shown on previous pages. So I filled these holes up, the dash will eventually be sprayed matt black.

Edited by Alburglar, 08 March 2007 - 11:44 PM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users