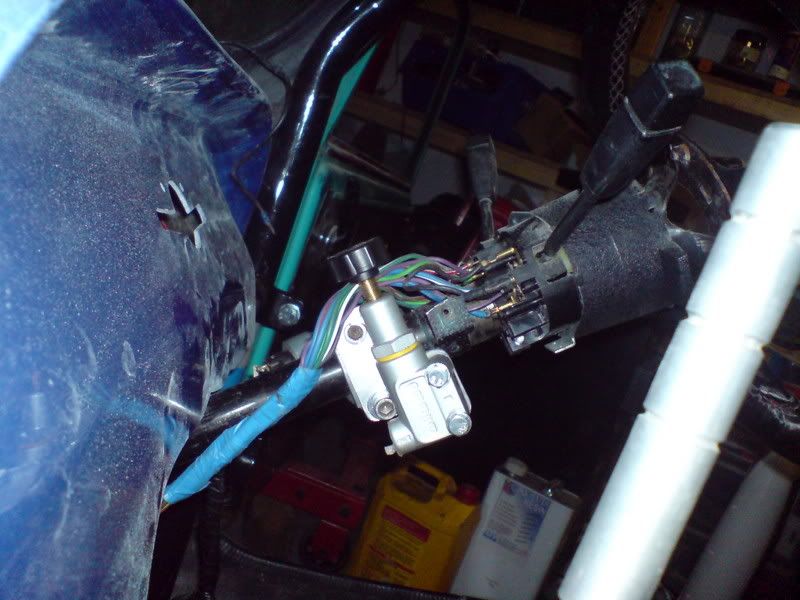

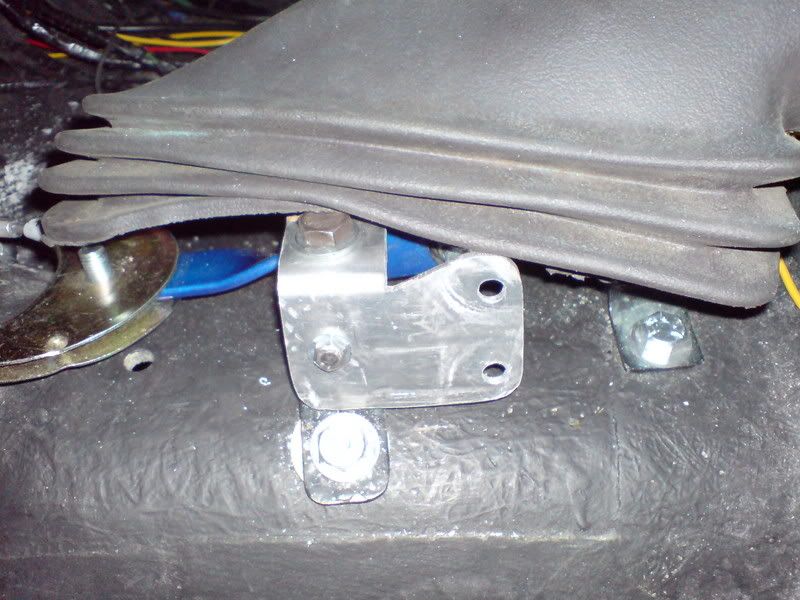

Latest progress: I've made up the studs I need to make my inner arches. Nothing special just some bolts welded to steel plate to stop the studs from turning inside the fibreglass when I do the nuts up.

Next I fitted a baffle to the sump. I bought one off ebay. It turned up with vague instructions so I'll go into some detail here for the benifit of others. It is a laser cut, but I had to file it down in numerous places to get it to fit, overall tho I'm happy with it. In order to fit I had to:

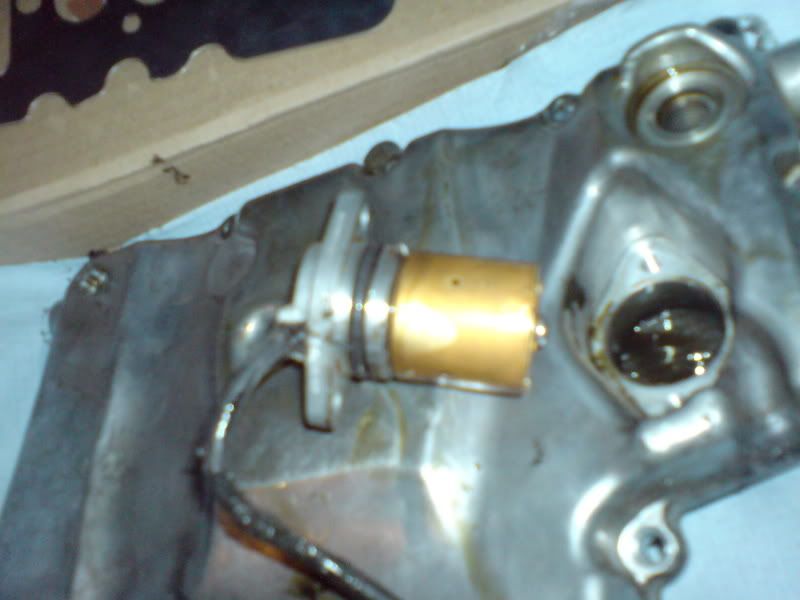

Remove sump. Note the oil level sender. The instructions said that the cylindrical sender parts needs to be discarded and the rest of it used just to plug the hole in the sump. I didn't fancy that so I modified the baffle plate some more.

This is what the engine side of the sump looks like

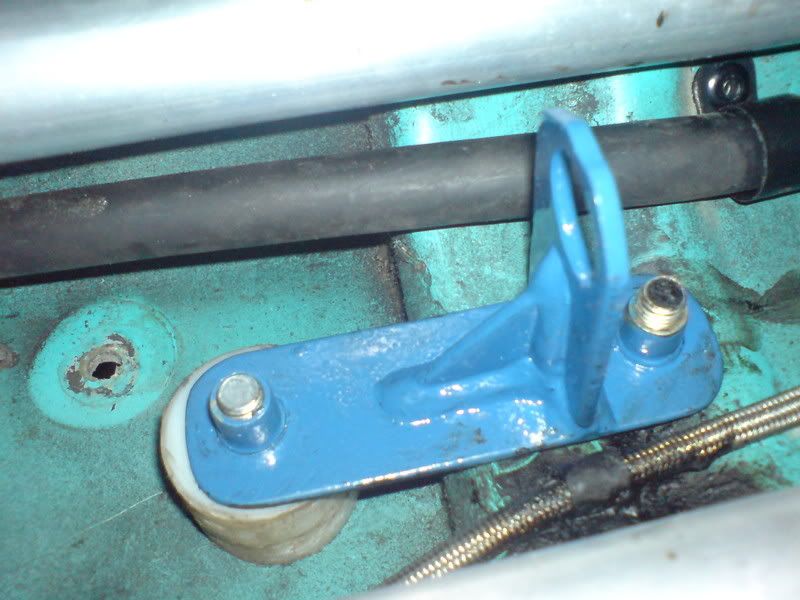

You need to remove these bits:

The kit cam with a collar to fit over the pressure relief valve

In order to modify the baffle plate, I trial fitted it and put the sump back on with the oil sender removed. I then drew round the hole with a marker pen, so I knew where to make a hole in the plate.

I took it all apart again and cut the hole out, refitted all the bits and this is what it looks like

Just need to get a new sump gasket. before I refit the sump.