Supercharged K20a2 Vtec - Race Spec

#721

Posted 17 November 2011 - 02:01 PM

What CAD have you used for these drawings?

Are those bolts with springs off the shelf?

Could you post a pic of the connections as they are now so we can see the difference?

Many thanks,

Al

#722

Posted 17 November 2011 - 02:38 PM

Epic mate, love it.

What CAD have you used for these drawings?

Are those bolts with springs off the shelf?

Could you post a pic of the connections as they are now so we can see the difference?

Many thanks,

Al

Hi Al

I use Autodesk Inventor for the drawings.

The bolts are simply Stainless Steel M8x60 with a 2x13x35mm Compression spring, the flanges nearest the nut are threaded and the nut locks off the bolt this way you can set the amount of compression on the spring/flange.

Below is one of the few pictures I have of the exhaust when I first got it, you can see that the pipes simply slide into on another and are held together by a tension spring that clips onto two loops either side of the pipe mating - this is regularly used and is a good cheap way of building exhausts, only down side is they leak.

Edited by cptkirk, 17 November 2011 - 02:43 PM.

#723

Posted 17 November 2011 - 03:44 PM

#724

Posted 17 November 2011 - 03:55 PM

#725

Posted 17 November 2011 - 04:27 PM

I did think that but then I thought that it had been held together so far with springs so it cant all be bad. As to the specifics of the effect of the heat on a spring I will leave to those that know that kind of stuff, I havent got the room in the brain to learn all that and as you say it wont take much to spanner some more on if it became an issue over time. OEM's use sprung joints on exhausts so I guess it should work OK.....

Edited by cptkirk, 17 November 2011 - 04:28 PM.

#726

Posted 17 November 2011 - 08:38 PM

#727

Posted 18 November 2011 - 07:31 AM

Nice post of the track day tyre guide, that may be useful in the near future!

My pleasure.

#728

Posted 20 November 2011 - 06:49 PM

#729

Posted 21 November 2011 - 08:23 AM

Looks awesome mate, what do you wreckon the final cost will be?

Thats a bit of an open question as it has been completed and the things posted recently are upgrades, however in an effort to answer you I would say that I have spent near to 40K on the car once these mods are done. I am currently aiming to get the car to the 500BHP/Tonne mark, which I will be very happy with - well until I get used to it then maybe look for some more power.....

#730

Posted 21 November 2011 - 01:42 PM

Al

#731

Posted 21 November 2011 - 10:48 PM

Many thanks for the reply, clear to see the aim of the flanges and springs when compared to the existing setup, I presume you couldn't weld the whole thing solid due to not being able to get it out?

Al

I wouldnt want a fully welded exhaust as it still has to move around a little, so if you had it all welded it would most likely crack on a weld. Also as you pointed out it might be a royal pain to remove if it were all one unit.

#732

Posted 21 November 2011 - 10:56 PM

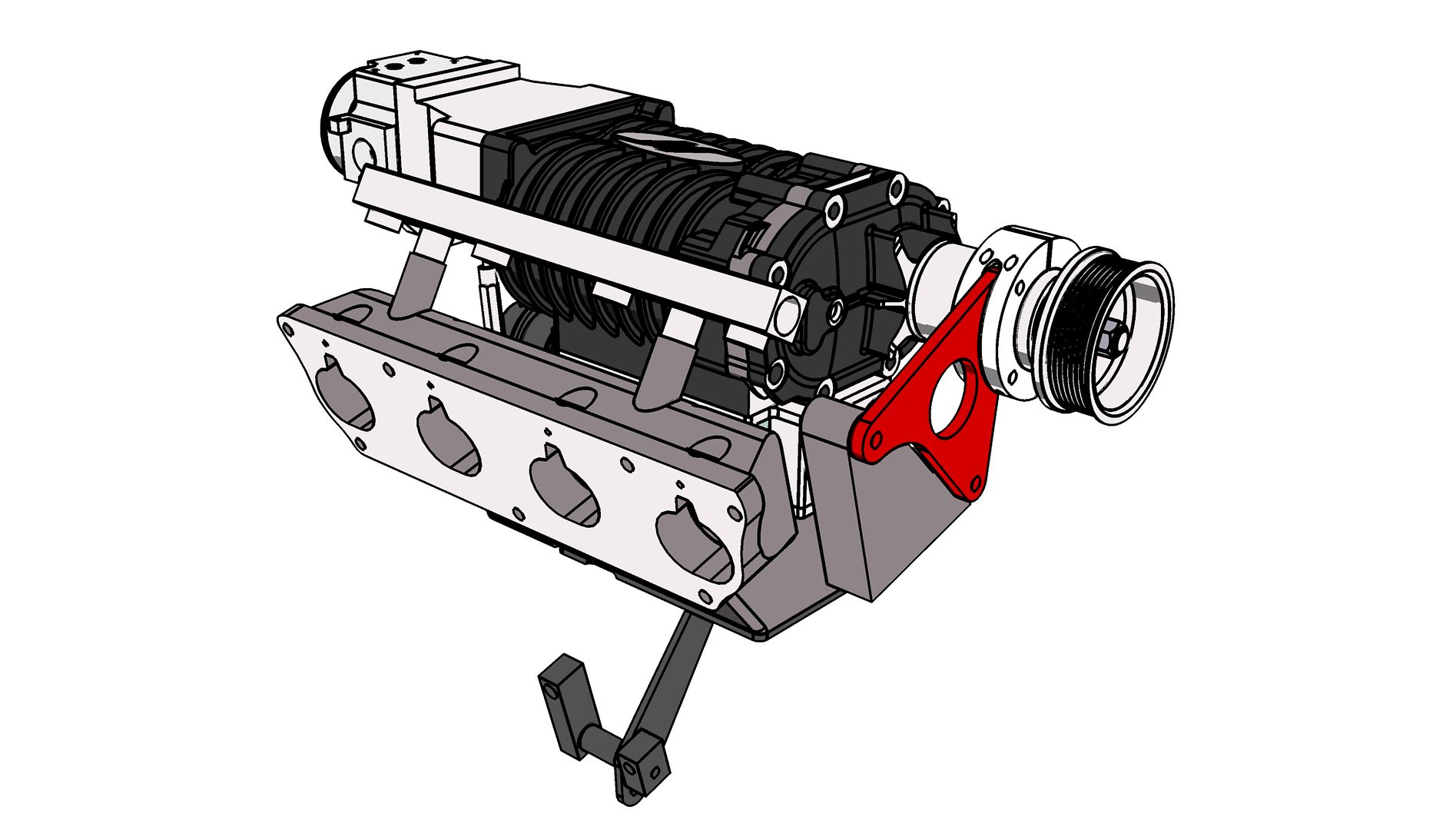

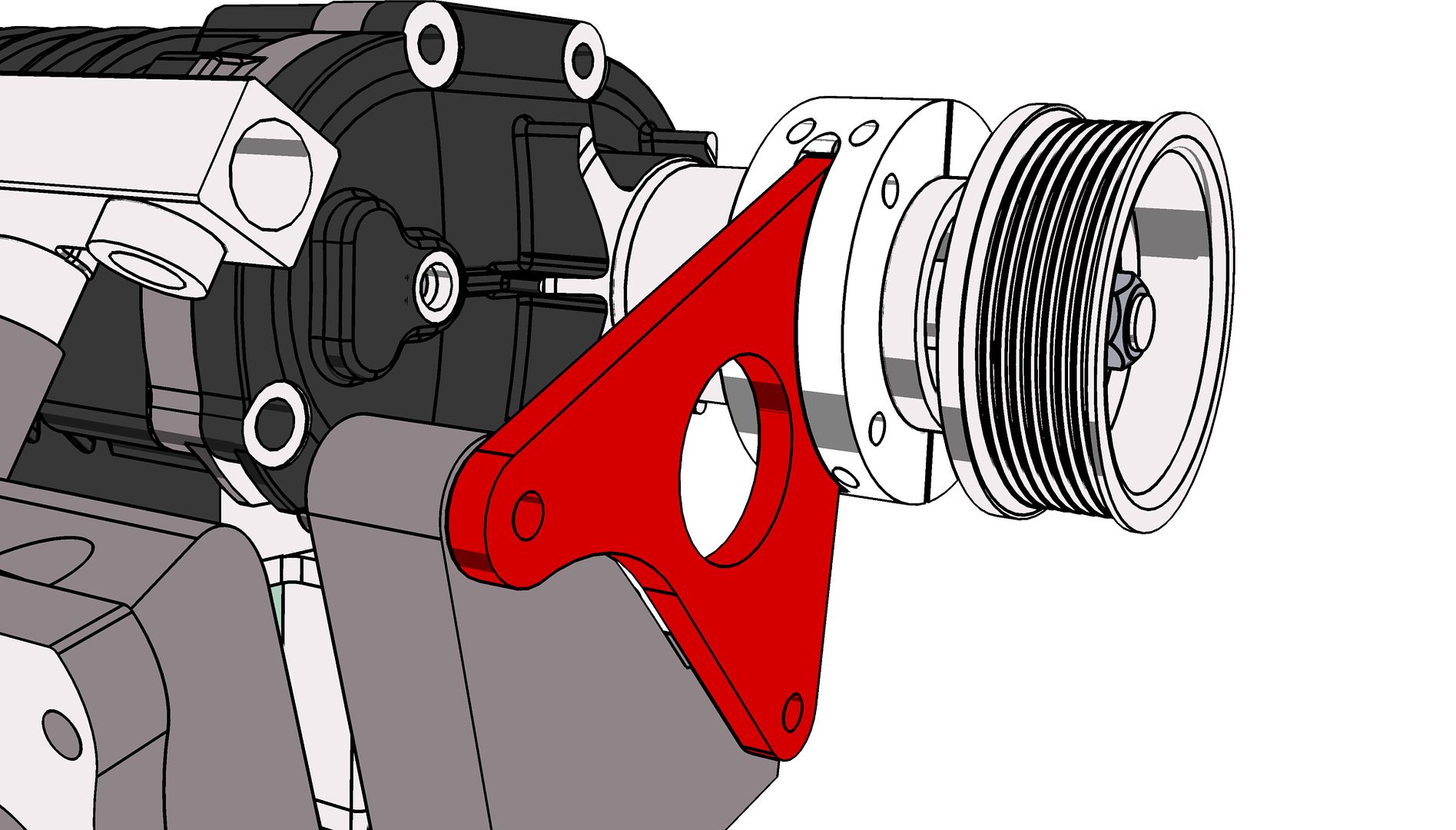

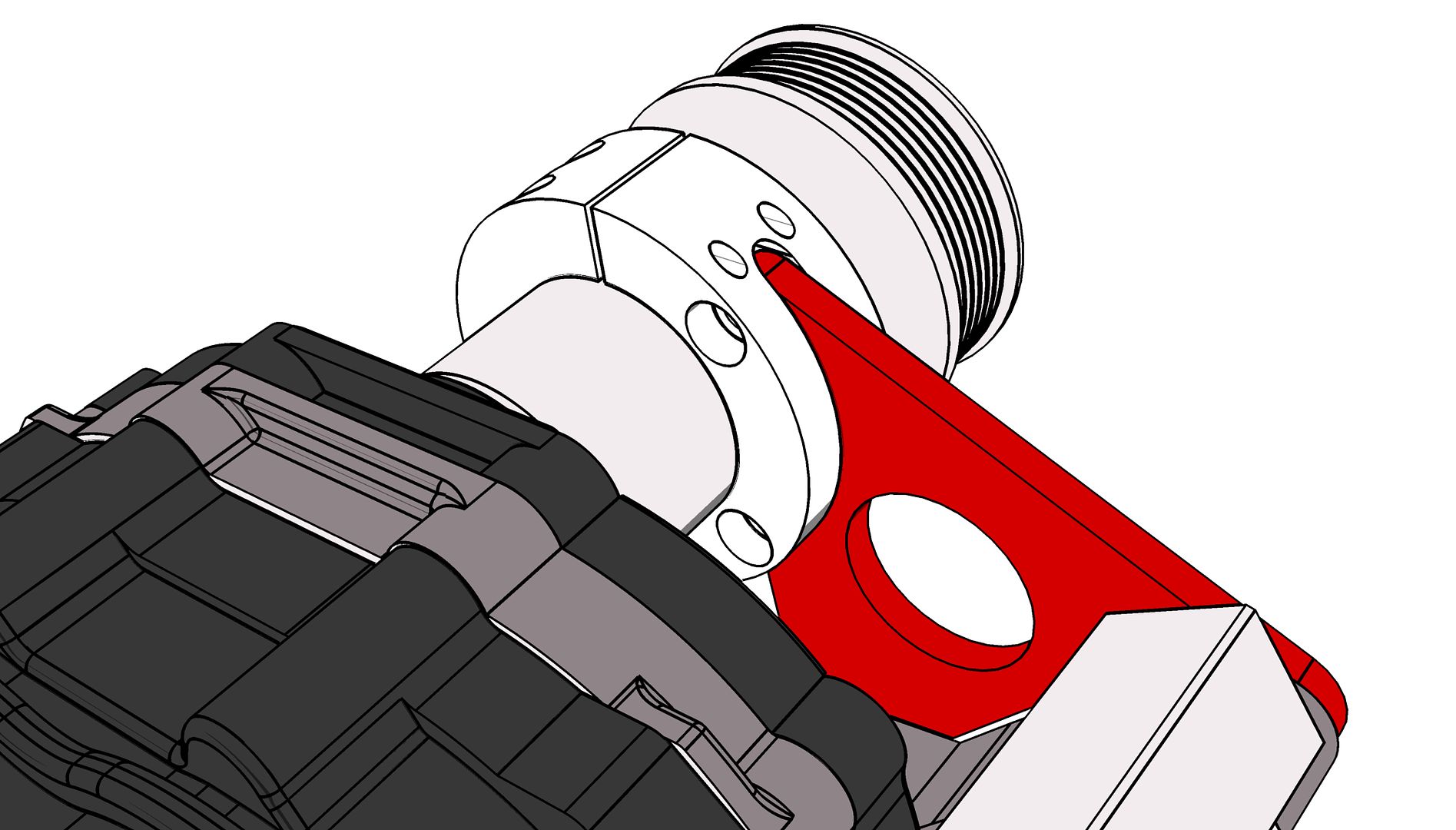

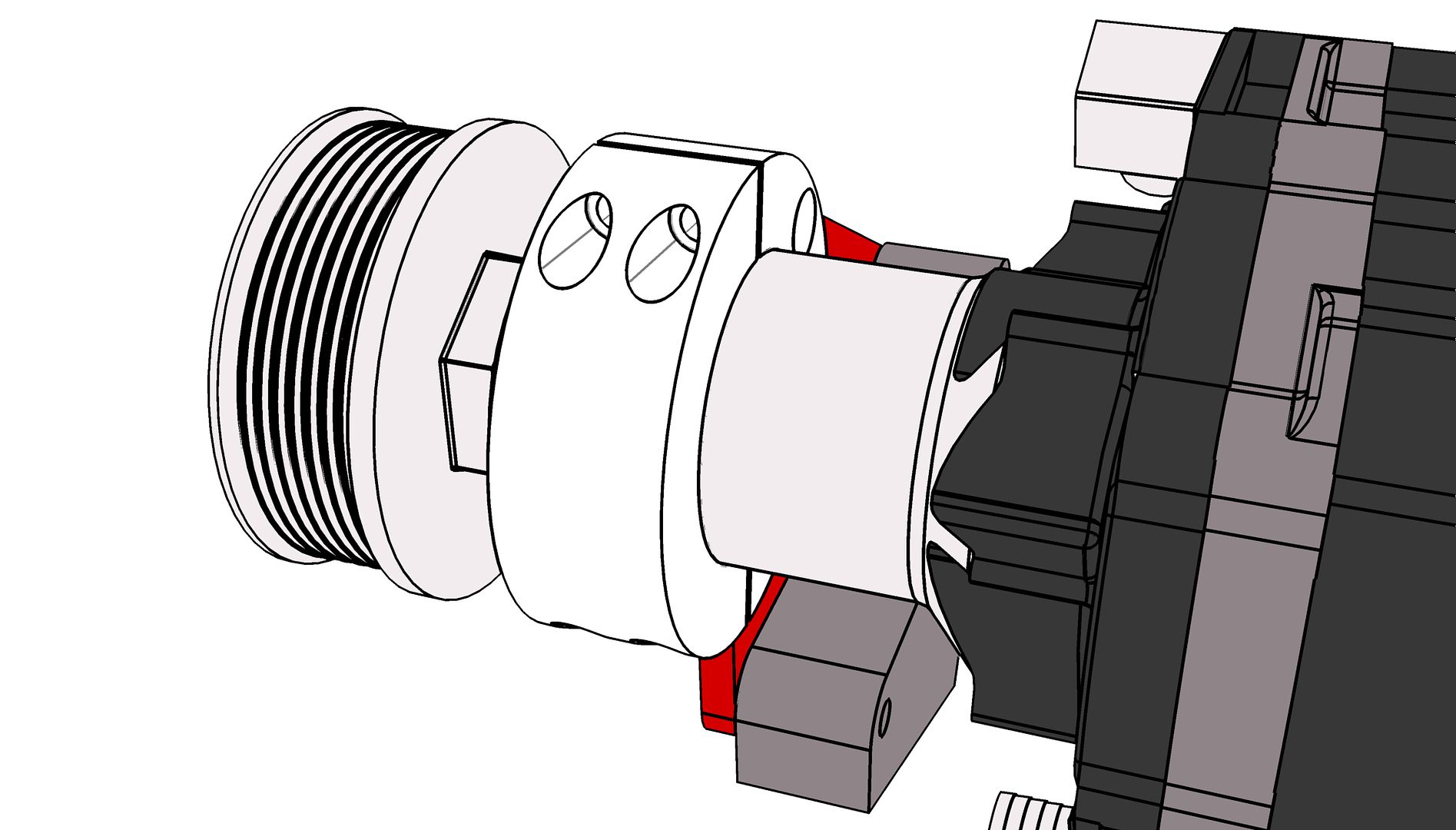

Another one of my winter mods will be a snout clamp to help with the extra forces that will be placed on the pulley and supercharger when the blower starts to be spun faster. Again I have been through a few design changes with this one but settle for what you will see below. I have the billet for the clamp sat on my table in front of me and plan to get some machining done asap, with the help of my good mate Stevie G.

So here are a few renders of what its going to look like, its a bit chunky but I might cut some fins into it to help dissipate some heat as the snout gets really quite hot, due to the deep groove bearing being used.

I hope to soon be able to show you the real thing of some of these parts, but even more I want to get them on the car and get it running again.....

.

#733

Posted 22 November 2011 - 07:52 AM

... Who needs cad mock ups anyway?

I do.

As it greatly reduces cost and time when designing new parts......

#734

Posted 22 November 2011 - 12:28 PM

#735

Posted 22 November 2011 - 01:14 PM

Maybe a CAD job for you in the near future with those skills...?

3 user(s) are reading this topic

0 members, 3 guests, 0 anonymous users