Are you going for a full length inner sill to go in there?

If I was a sensible human being I probably should've done the whole lot in one go as you illustrated, that does look very neat, but as the cross member was still perfect and it was just the floor/sills that had gone, I set about patching it all up. I think it's good practice anyway having to make patches myself, we get spoilt with Minis being able to buy anything we need!

Some good work going on there Sven, you will have it done in no time.

Cheers buddy.

---

Right then, time for an update. It felt like I hadn't done too much since I last updated, but it's surprising just what gets done doing a few hours a week after work and at weekends.

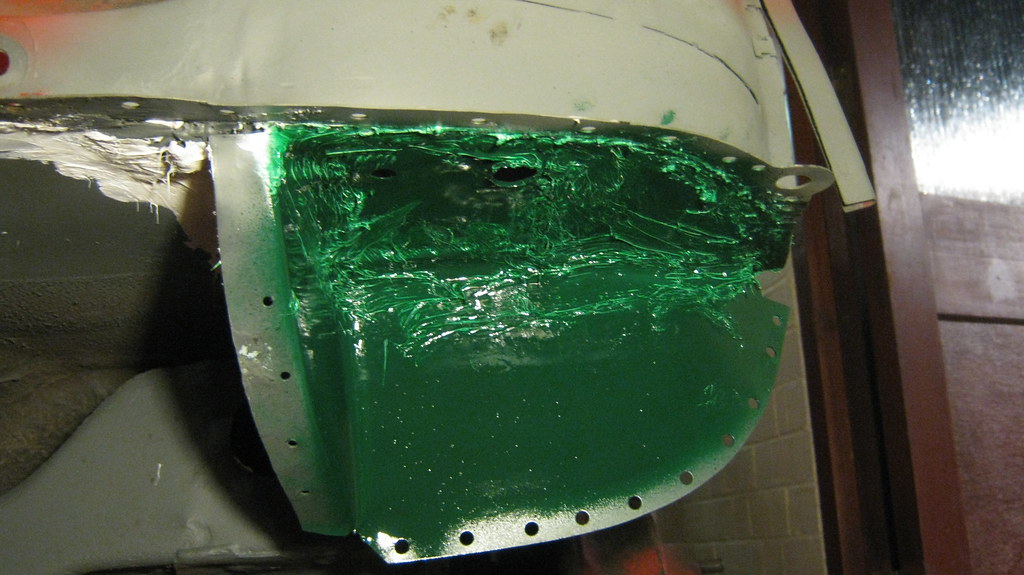

Last time I left you with that patch on the flitch I was just starting to cut off. Well, I err... cut it all off.

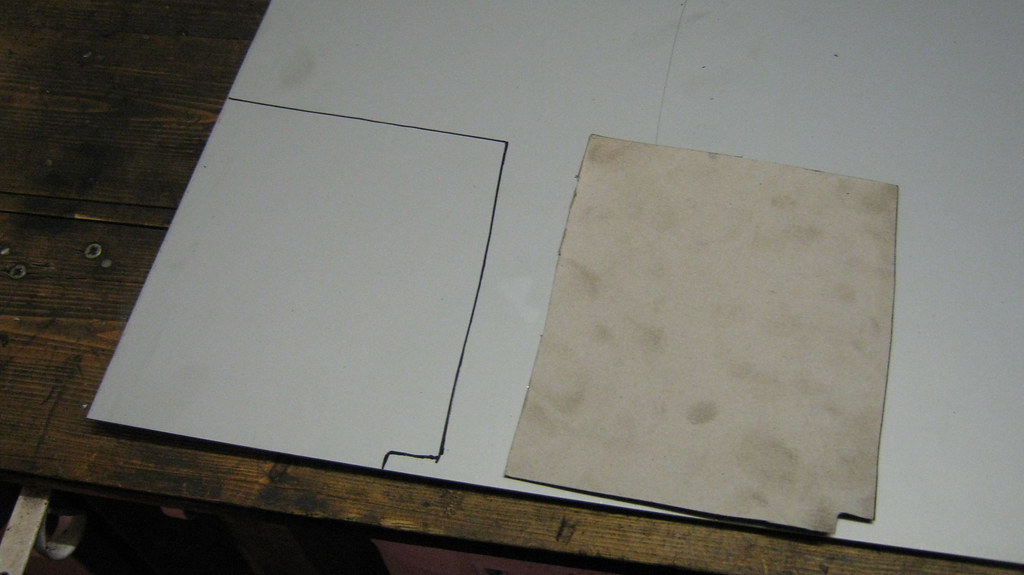

IMG_0006 by Sven Cumner, on Flickr

IMG_0006 by Sven Cumner, on Flickr

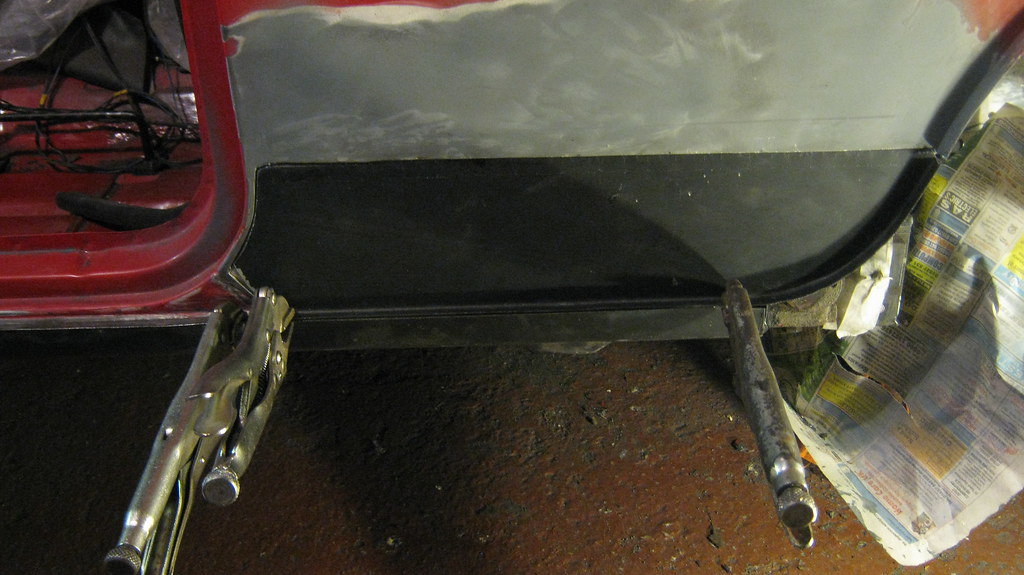

Then I clamped my replacement sill in place to give me a better idea of the hole I needed to fill, as the patch I cut off was a bit manky and bent.

IMG_0007 by Sven Cumner, on Flickr

IMG_0007 by Sven Cumner, on Flickr

IMG_0008 by Sven Cumner, on Flickr

IMG_0008 by Sven Cumner, on Flickr

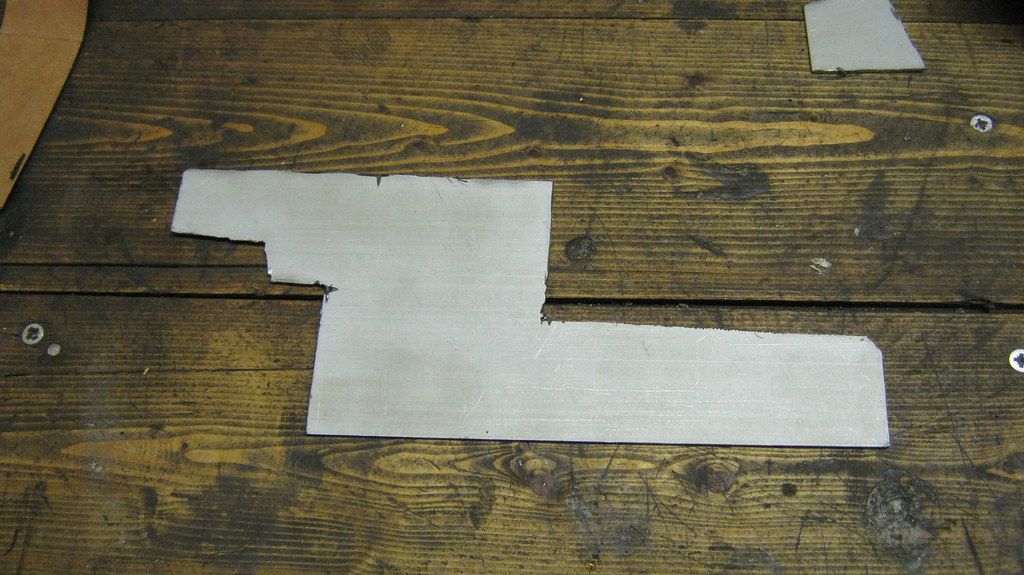

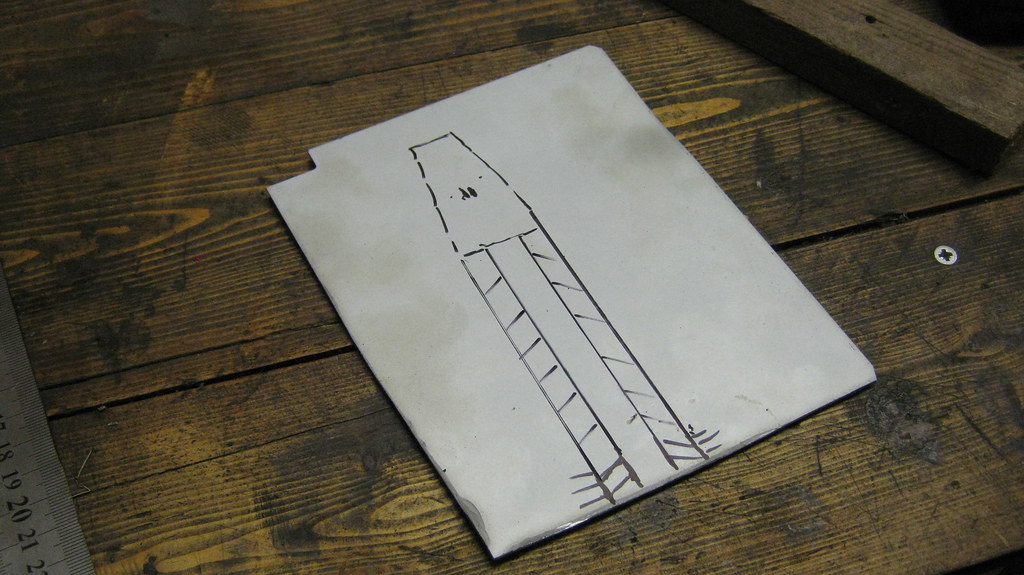

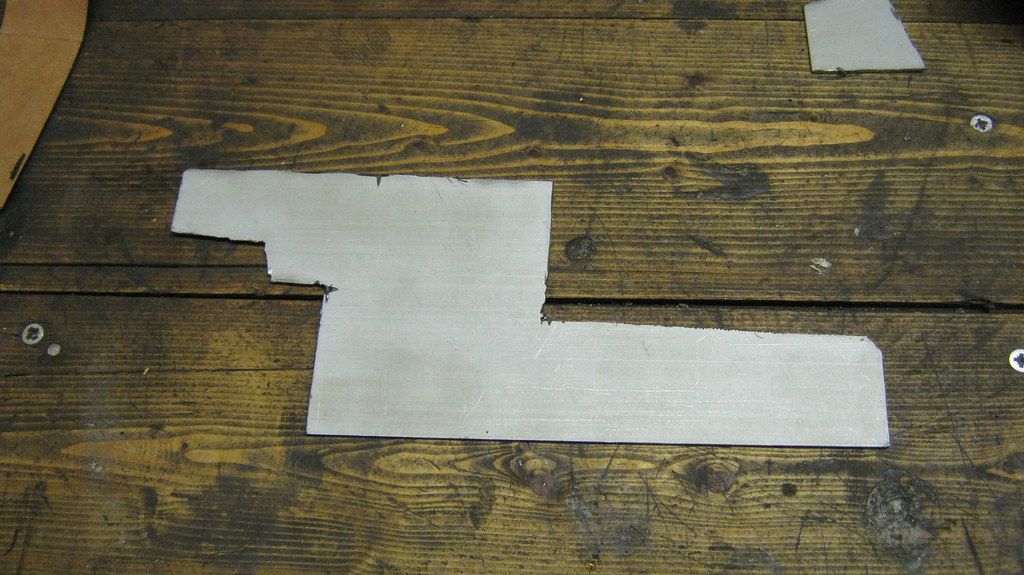

Then I made myself a cardboard template from a most useful Weetabix packet.

IMG_0009 by Sven Cumner, on Flickr

IMG_0009 by Sven Cumner, on Flickr

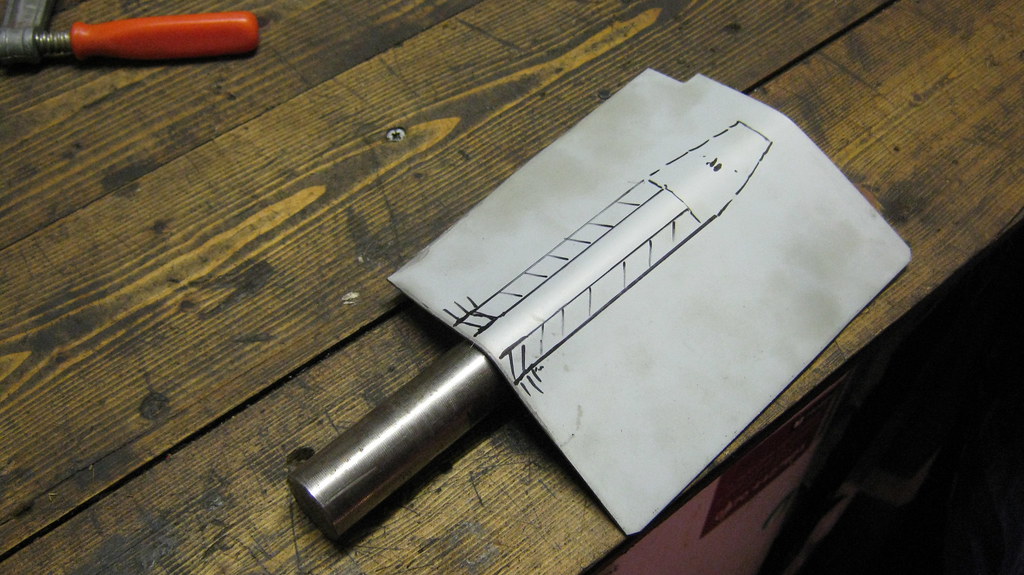

A bit of jiggery pokery with a pen and some steel sheet (oh and a hammer) and I had myself a patch.

IMG_0012 by Sven Cumner, on Flickr

IMG_0012 by Sven Cumner, on Flickr

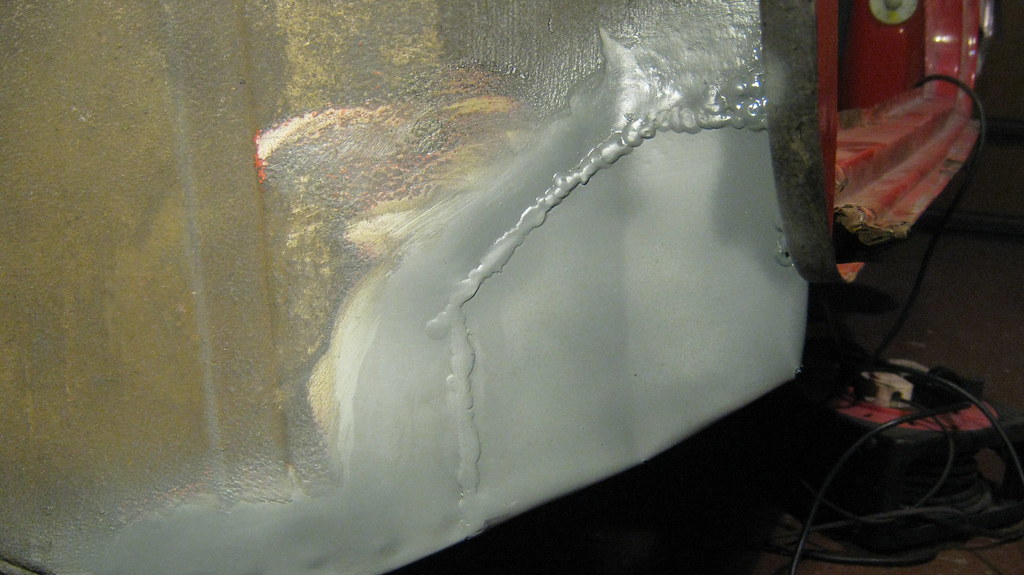

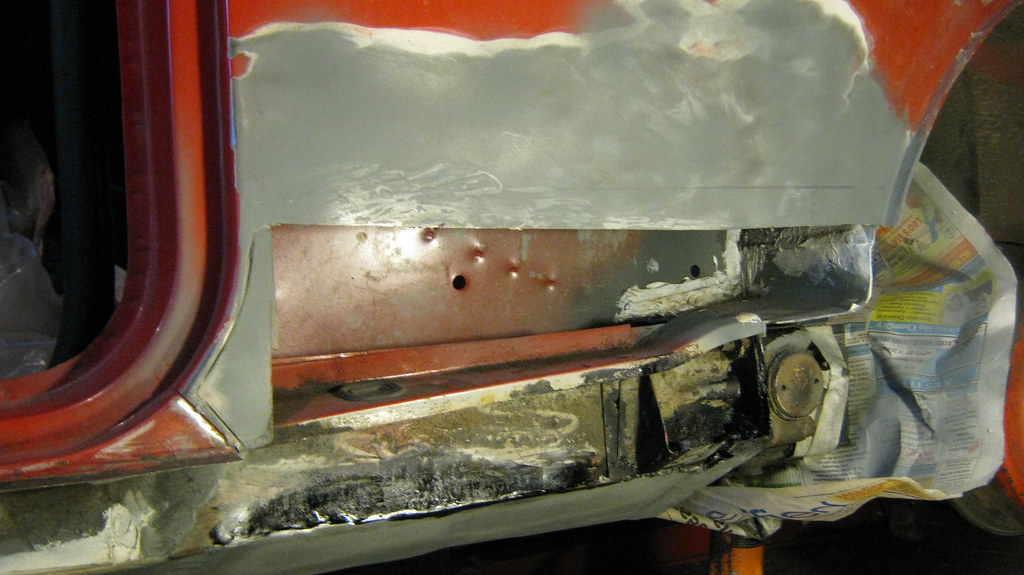

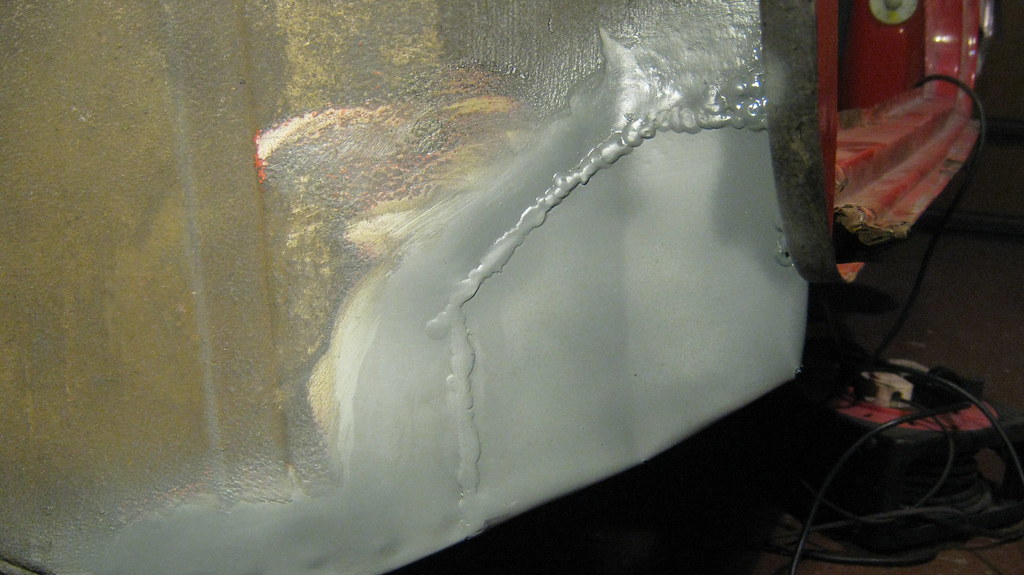

Which was then melted in to the car.

IMG_0014 by Sven Cumner, on Flickr

IMG_0014 by Sven Cumner, on Flickr

I'll fill those gaps later...

IMG_0017 by Sven Cumner, on Flickr

IMG_0017 by Sven Cumner, on Flickr

Then I ground down the welds a bit and but on some zinc primer. I've since ground the welds down some more so it's a bit less obvious a patch, but no pics unfortunately.

IMG_0018 by Sven Cumner, on Flickr

IMG_0018 by Sven Cumner, on Flickr

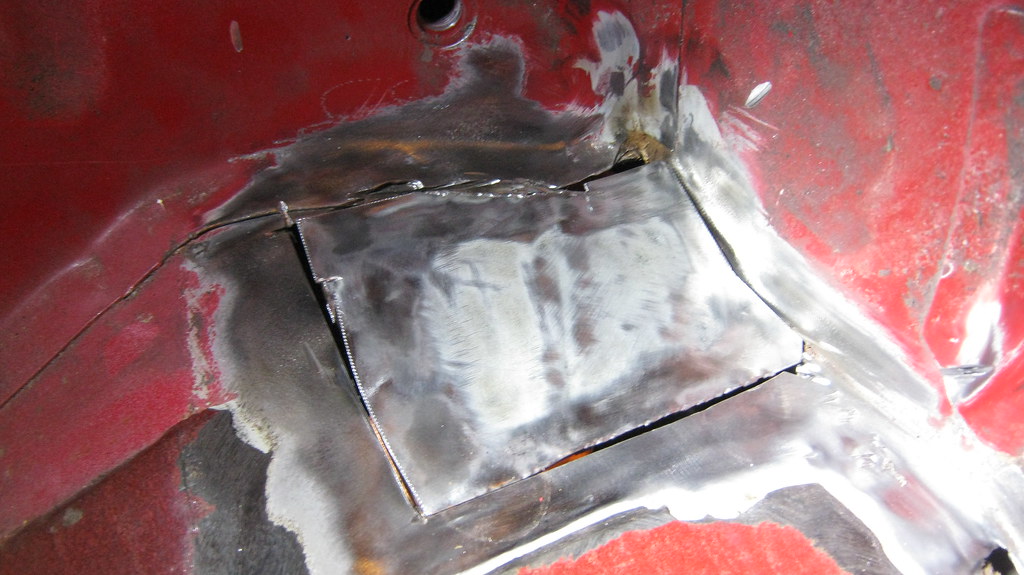

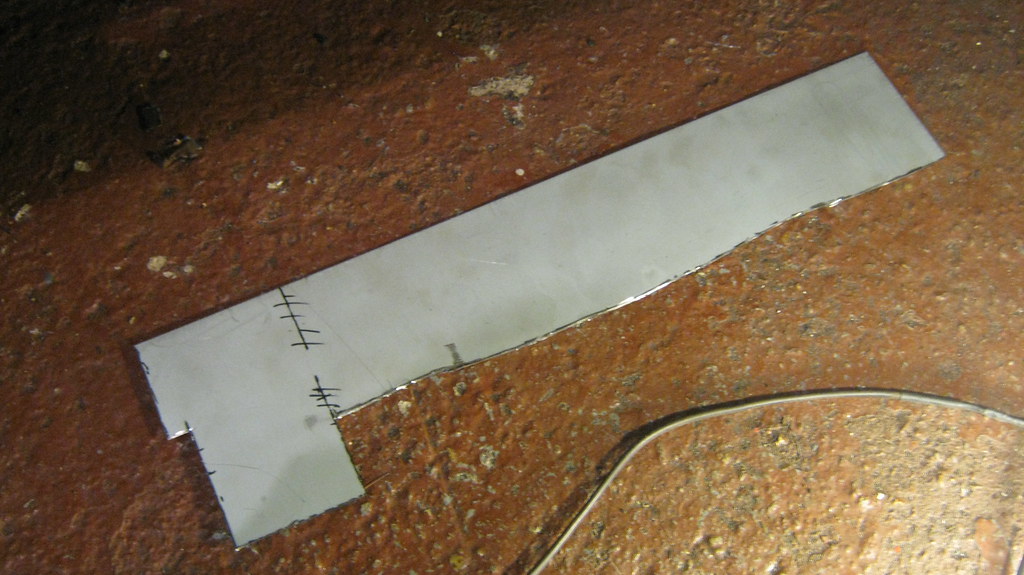

After that corner was solid, I set about filling this hole I'd made in the floor pan.

IMG_0019 by Sven Cumner, on Flickr

IMG_0019 by Sven Cumner, on Flickr

I had a cheap floor pan replacement panel that I cut a section out of.

IMG_0020 by Sven Cumner, on Flickr

IMG_0020 by Sven Cumner, on Flickr

IMG_0022 by Sven Cumner, on Flickr

IMG_0022 by Sven Cumner, on Flickr

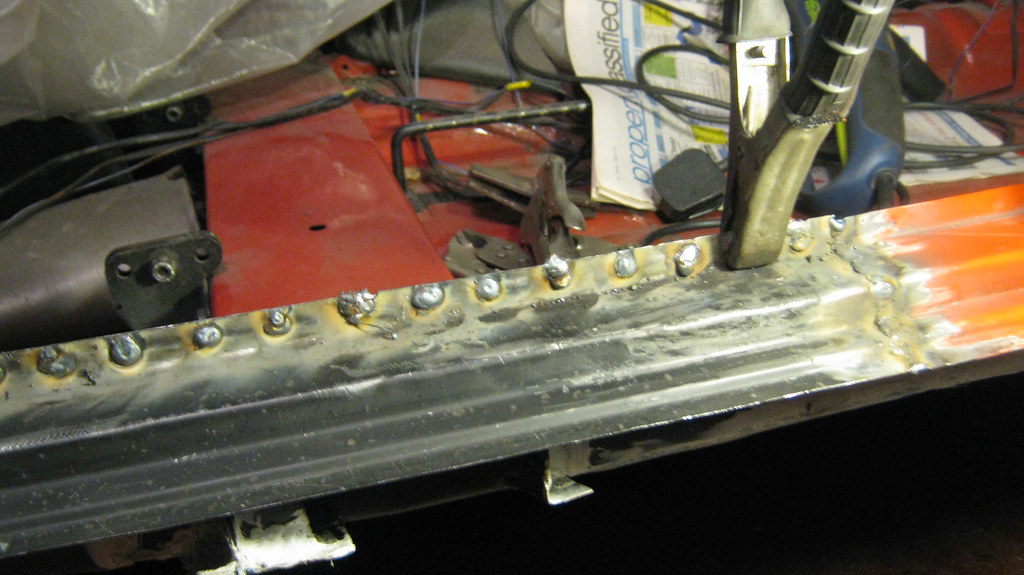

Which then also got stitched in to the floor pan.

IMG_0028 by Sven Cumner, on Flickr

IMG_0028 by Sven Cumner, on Flickr

IMG_0030 by Sven Cumner, on Flickr

IMG_0030 by Sven Cumner, on Flickr

After a bit of dressing on the welds, it actually came out better than I'd expected.

IMG_0032 by Sven Cumner, on Flickr

IMG_0032 by Sven Cumner, on Flickr

IMG_0035 by Sven Cumner, on Flickr

IMG_0035 by Sven Cumner, on Flickr

After doing this front section with the repair panel I had lying around, I decided to the rest of the floor/inner sill in two main chunks, basically the middle and the rear. So I started off by looking at the middle section. Few holes to fill I think...

IMG_0036 by Sven Cumner, on Flickr

IMG_0036 by Sven Cumner, on Flickr

Rust be gone! Some of it anyway...

IMG_0037 by Sven Cumner, on Flickr

IMG_0037 by Sven Cumner, on Flickr

I decided I'd leave the inner sill section by the cross member to another patch as the rot there went in to the door step too. I didn't want to cut too much out all in one go as I didn't want to bother bracing anything and was a bit worried about distorting something. Bit of an arse-about-face way of doing things but I don't think it went too badly. Anyway...

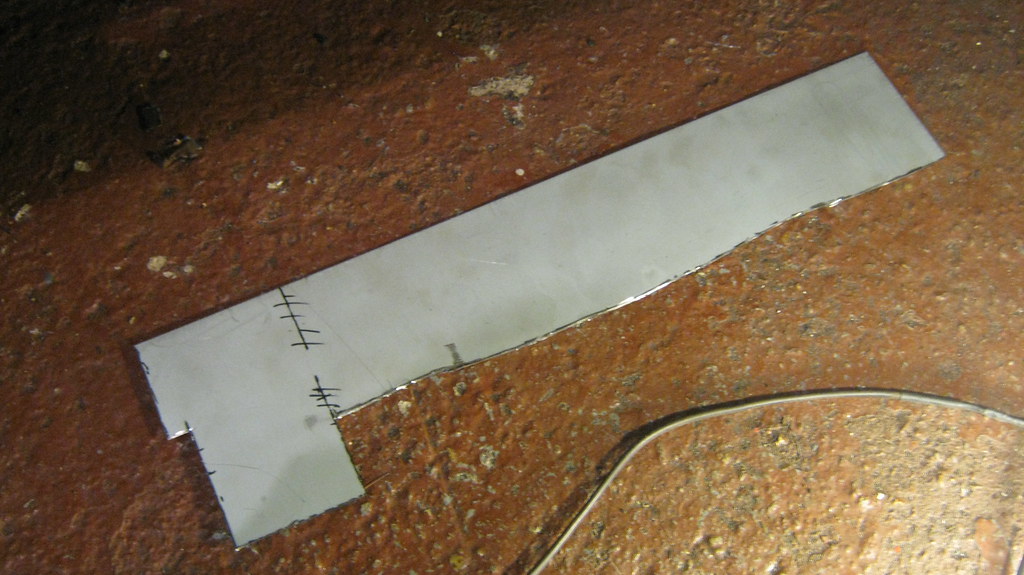

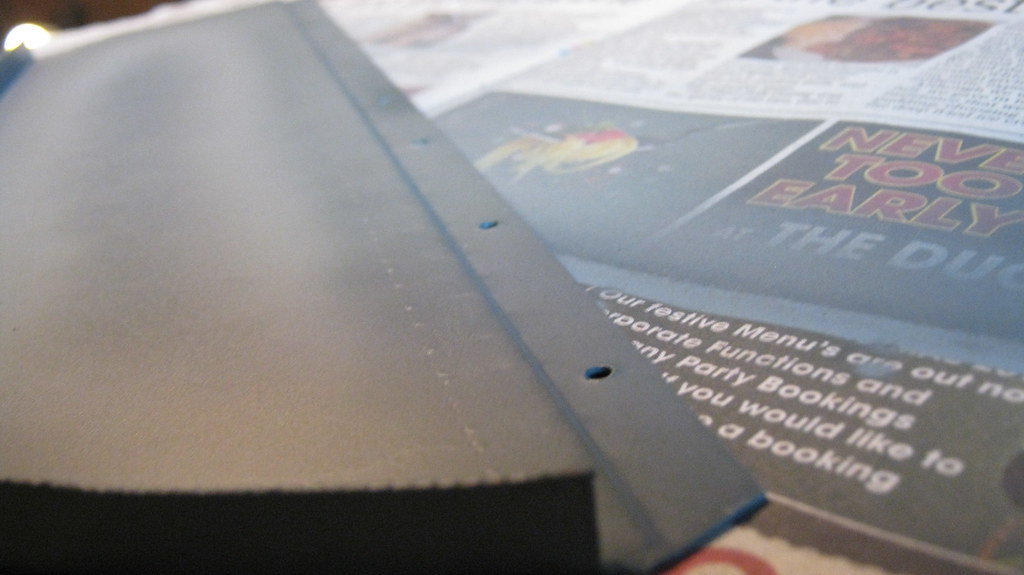

I made myself a patch, complete with wavy cut lines to match my original wavy cut lines.

IMG_0038 by Sven Cumner, on Flickr

IMG_0038 by Sven Cumner, on Flickr

Did some bending and drilled some holes to plug weld to the underside of the cross member flange.

IMG_0040 by Sven Cumner, on Flickr

IMG_0040 by Sven Cumner, on Flickr

Then I got jiggy with the welder again.

IMG_0041 by Sven Cumner, on Flickr

IMG_0041 by Sven Cumner, on Flickr

That crusty section in the middle in the photo above was what I was leaving for another patch, hence I didn't weld past a certain point on the top edge of that patch where the metal started getting a bit frilly.

Here's the patch from inside.

IMG_0042 by Sven Cumner, on Flickr

IMG_0042 by Sven Cumner, on Flickr

So next thing to do was patch that inner sill, which meant cutting off the rotten bits of the door step.

IMG_0043 by Sven Cumner, on Flickr

IMG_0043 by Sven Cumner, on Flickr

This plated area in the middle, in particular, needed to go...

IMG_0044 by Sven Cumner, on Flickr

IMG_0044 by Sven Cumner, on Flickr

It'd had a patch on the inside too, was pretty messy really.

IMG_0046 by Sven Cumner, on Flickr

IMG_0046 by Sven Cumner, on Flickr

There were a few bits of rot further forward on the door step, so I cut it all out up to a point where the rot stopped.

IMG_0048 by Sven Cumner, on Flickr

IMG_0048 by Sven Cumner, on Flickr

You see why I wanted to get the door step out of the way first now...

IMG_0050 by Sven Cumner, on Flickr

IMG_0050 by Sven Cumner, on Flickr

Jacking point was as strong as usual.

IMG_0051 by Sven Cumner, on Flickr

IMG_0051 by Sven Cumner, on Flickr

Gotta love that expanding foam I put in. (this is the underside of the door step section I cut off).

IMG_0054 by Sven Cumner, on Flickr

IMG_0054 by Sven Cumner, on Flickr

Damn my blurry photos, but here's the area once I'd cut all the rot out.

IMG_0053 by Sven Cumner, on Flickr

IMG_0053 by Sven Cumner, on Flickr

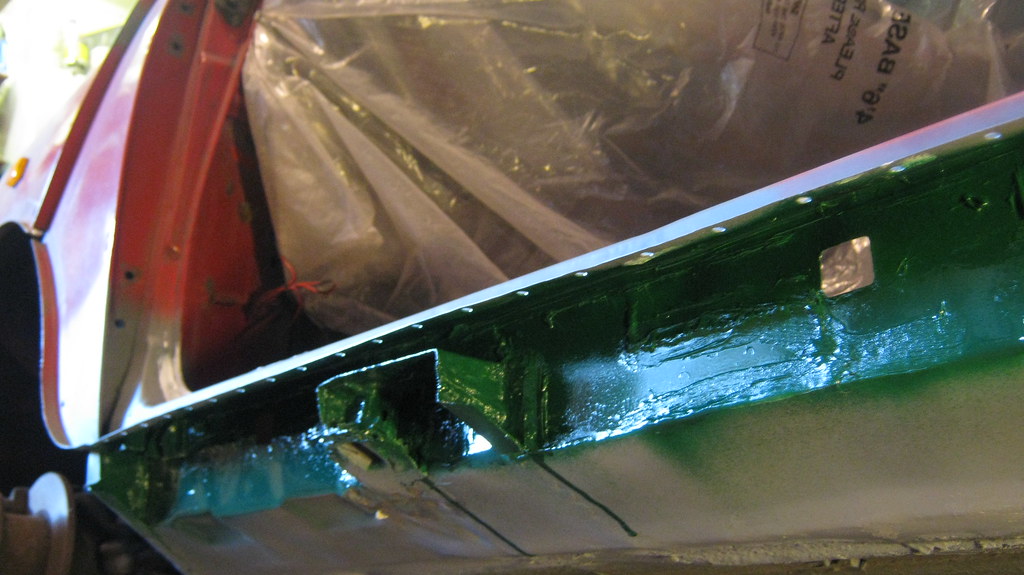

Once again, a patch was forged from the finest ebay Zintec steel.

IMG_0055 by Sven Cumner, on Flickr

IMG_0055 by Sven Cumner, on Flickr

And promptly put where it belonged.

IMG_0056 by Sven Cumner, on Flickr

IMG_0056 by Sven Cumner, on Flickr

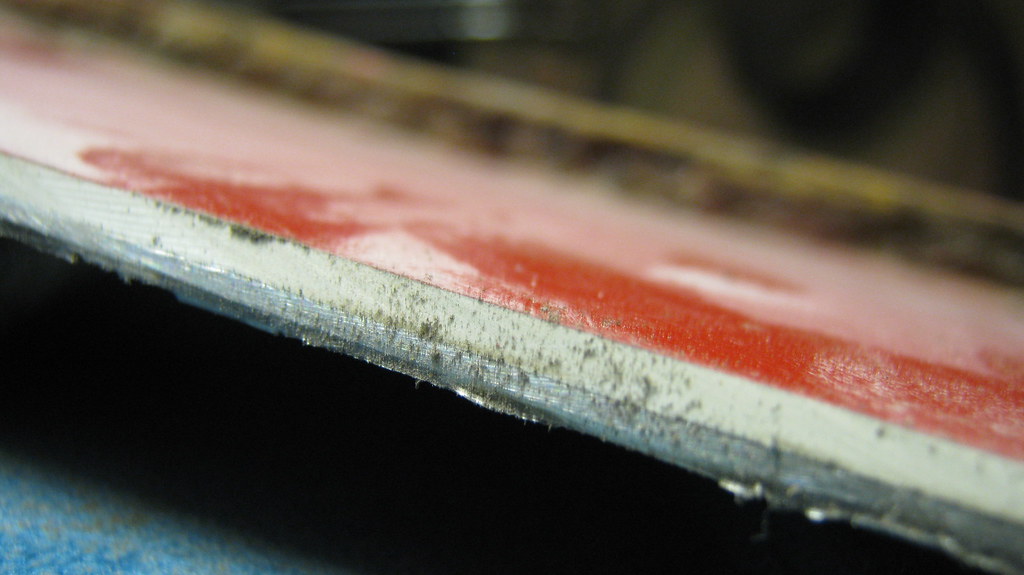

After a bit of a grind down, some zinc primer, and a shaky camera hand, it was looking alright.

IMG_0058 by Sven Cumner, on Flickr

IMG_0058 by Sven Cumner, on Flickr

IMG_0060 by Sven Cumner, on Flickr

IMG_0060 by Sven Cumner, on Flickr

After that lot was done, I had to replace that bit of door step I cut out, so I sliced off a slither of another repair panel I bought a few years ago. Then I trimmed it down to size and test fitted it.

IMG_0061 by Sven Cumner, on Flickr

IMG_0061 by Sven Cumner, on Flickr

I clamped the sill in place again on what was left of the original doorstep, just to line up the new doorstep section and make sure it'd all fit together okay. After a bit more finagling and some hole punching for plug welding, I got the doorstep section how I wanted it.

IMG_0062 by Sven Cumner, on Flickr

IMG_0062 by Sven Cumner, on Flickr

Still got a little hole to fill back there...

IMG_0063 by Sven Cumner, on Flickr

IMG_0063 by Sven Cumner, on Flickr

Anyways, with the doorstep section clamped in place, I fired up the welder and tacked the repair piece in. I then went and man-handled the passenger door back in to position (roughly) just to make sure I'd not messed it all up.

IMG_0064 by Sven Cumner, on Flickr

IMG_0064 by Sven Cumner, on Flickr

Looks like a suitably bad Rover-spec panel gap all the way along to me, I'll take that.

IMG_0065 by Sven Cumner, on Flickr

IMG_0065 by Sven Cumner, on Flickr

Then I started welding the section in properly and ran out of time, and that's where I'm currently at.

IMG_0066 by Sven Cumner, on Flickr

IMG_0066 by Sven Cumner, on Flickr

I'm finally seeing the light at the end of tunnel with all this welding, I need to finish off the door step, then make a patch for the rear of the floor, then just pop in the lower quarter repair panel and fit the new outer sill.

Almost there...