Hi all,

Big fan of TMF so much fantastic info and some incredible builds here! Not much of a typist but will try, I think this might be more of a visual build diary then anything but happy to chat with anyone.

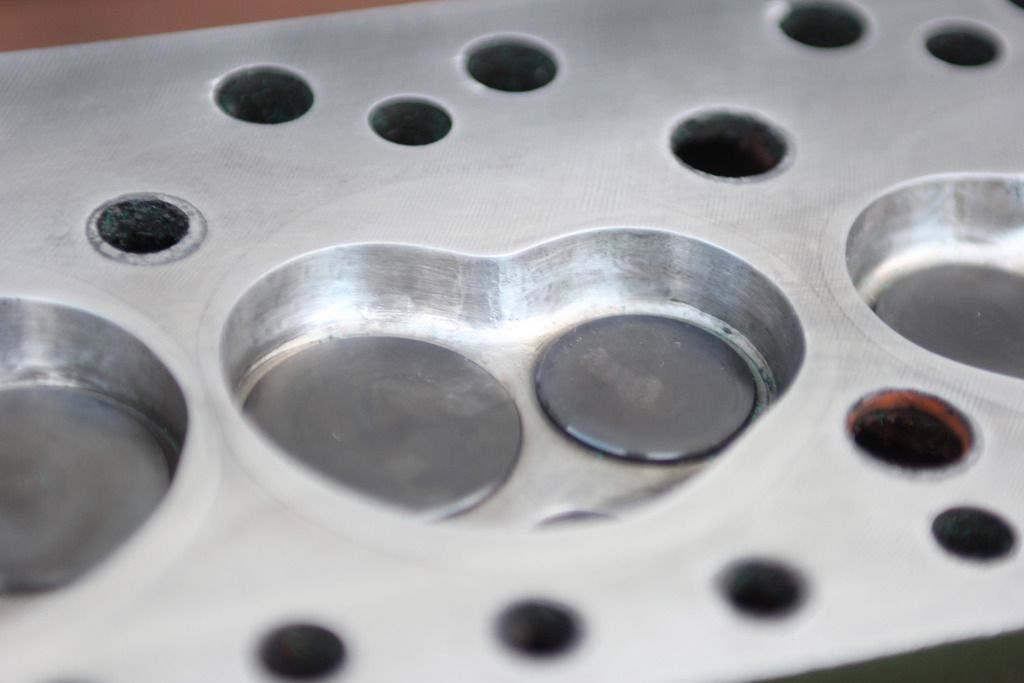

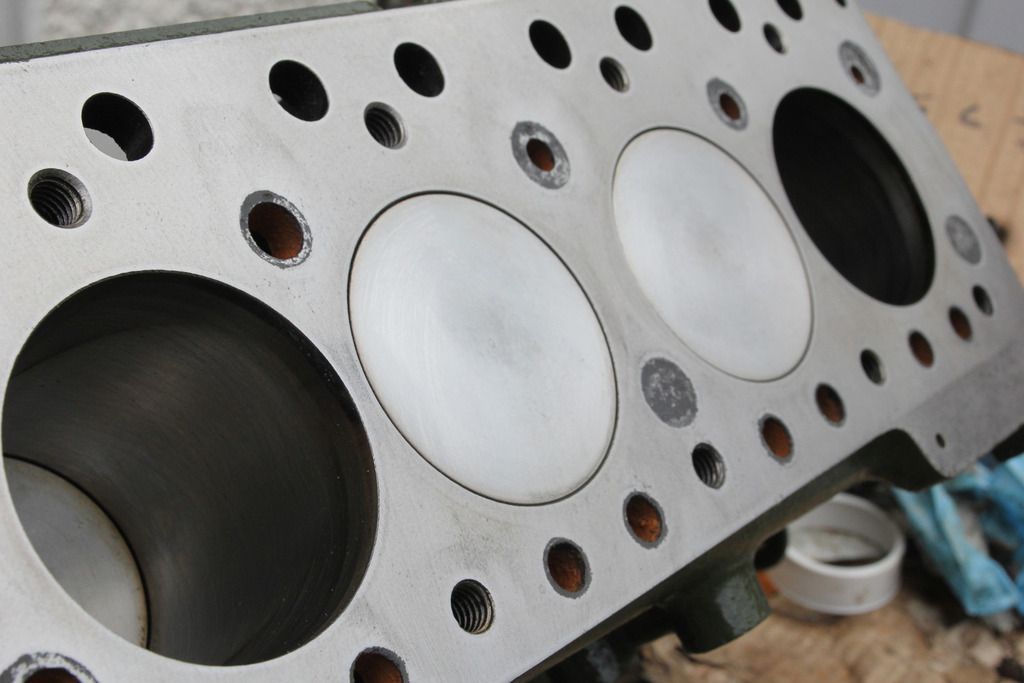

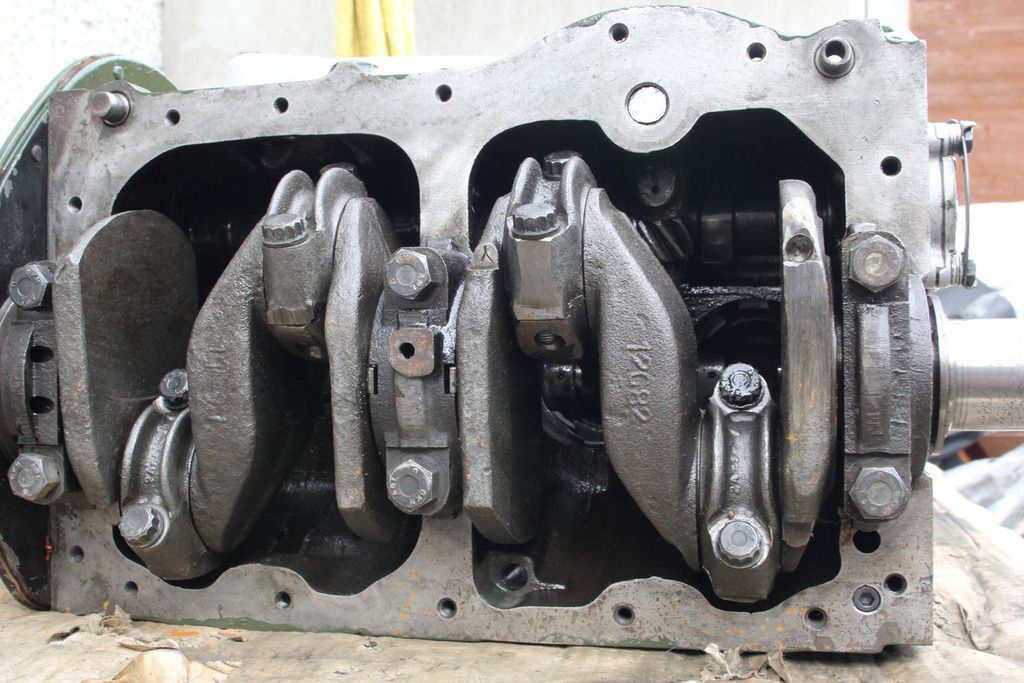

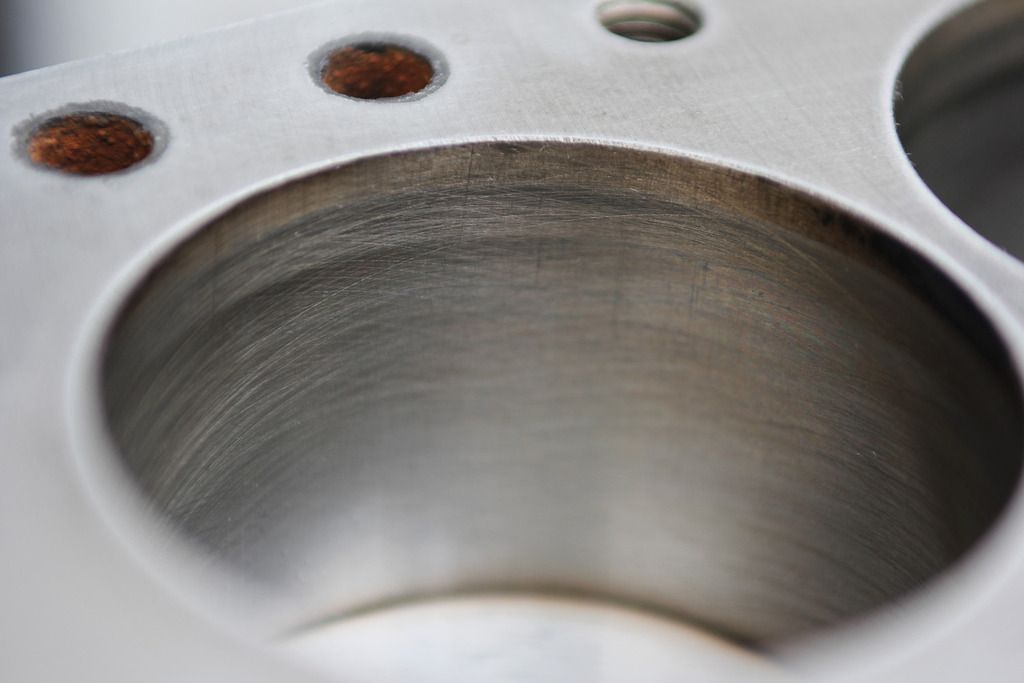

This car started as 1000HL that I bought when I was 16, Im now 37! I did a bit of a restoration the first time round which took me years as I have no garage so was dependent on friends lending me space. The usual rusted areas sills, doors, around rear windows etc. The car was used through college and I had a 1130cc small bore engine that I built while working in an engine builders. 12g295 ported head, fiat flat top lightweight pistons.

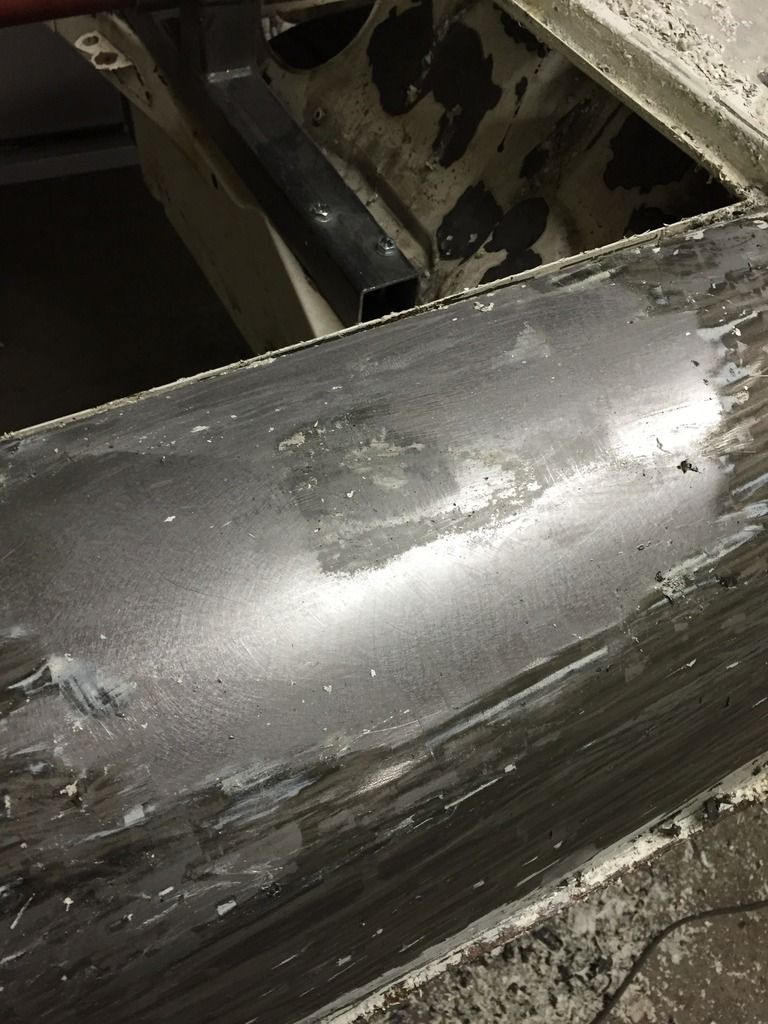

This was the engine after running for a few years before I sold it on. It obviously got a good clean but was still pretty good.