Well I have been busy. Had a week off this week so made some good progress.

Fitted some new drive shaft seals to the box, then fitted the shafts and built up the suspension.

Wasn't surprised about the angle of the shafts as I knew it would be bad. Would like to see it on the wheels to see if it changes any.

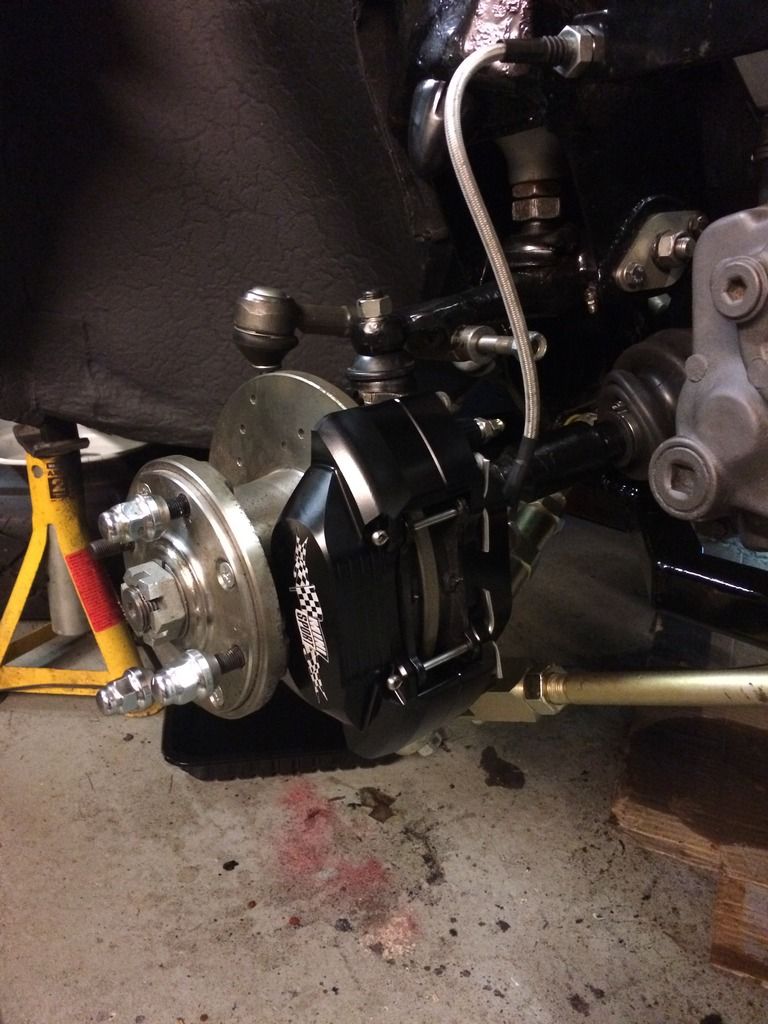

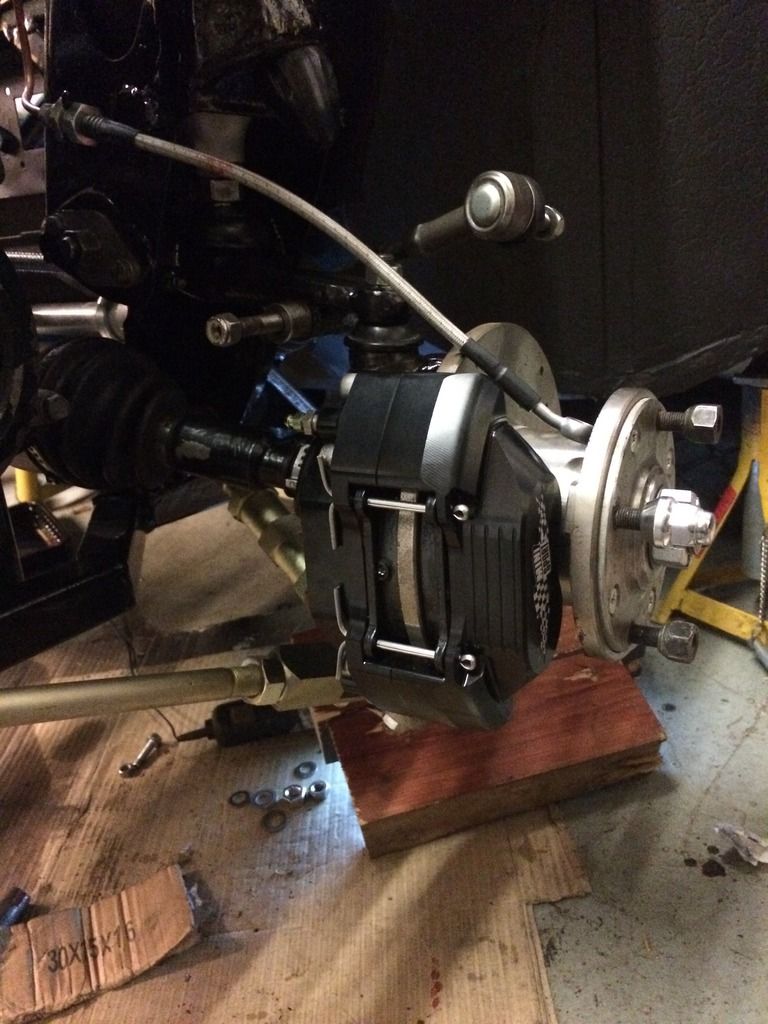

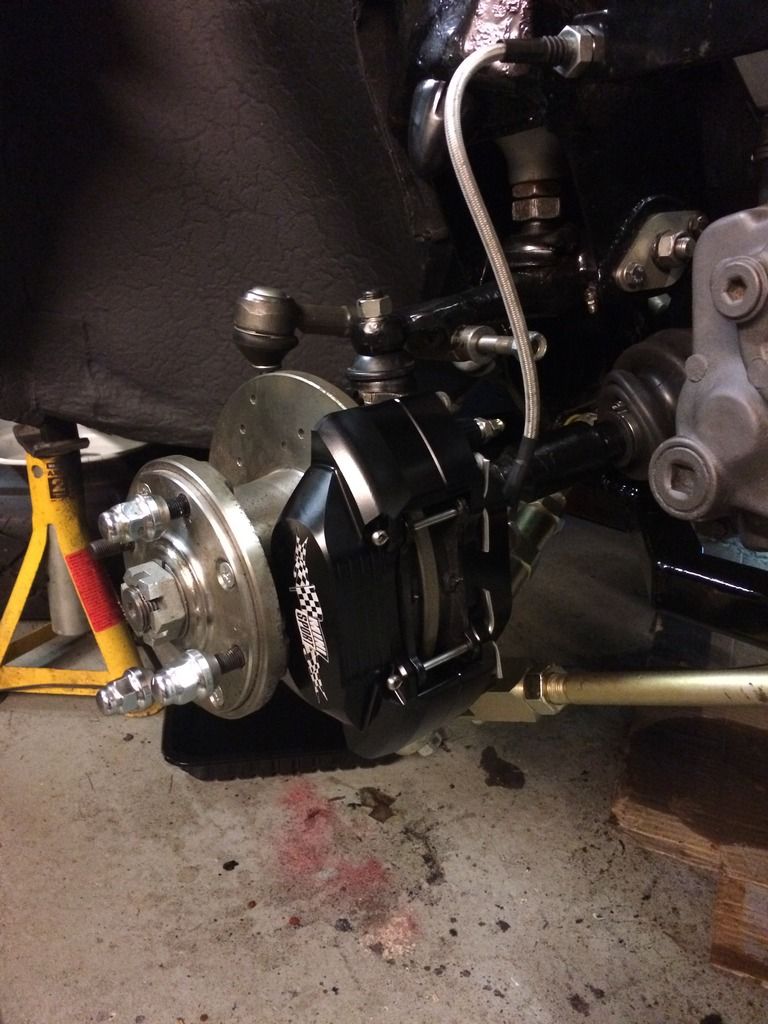

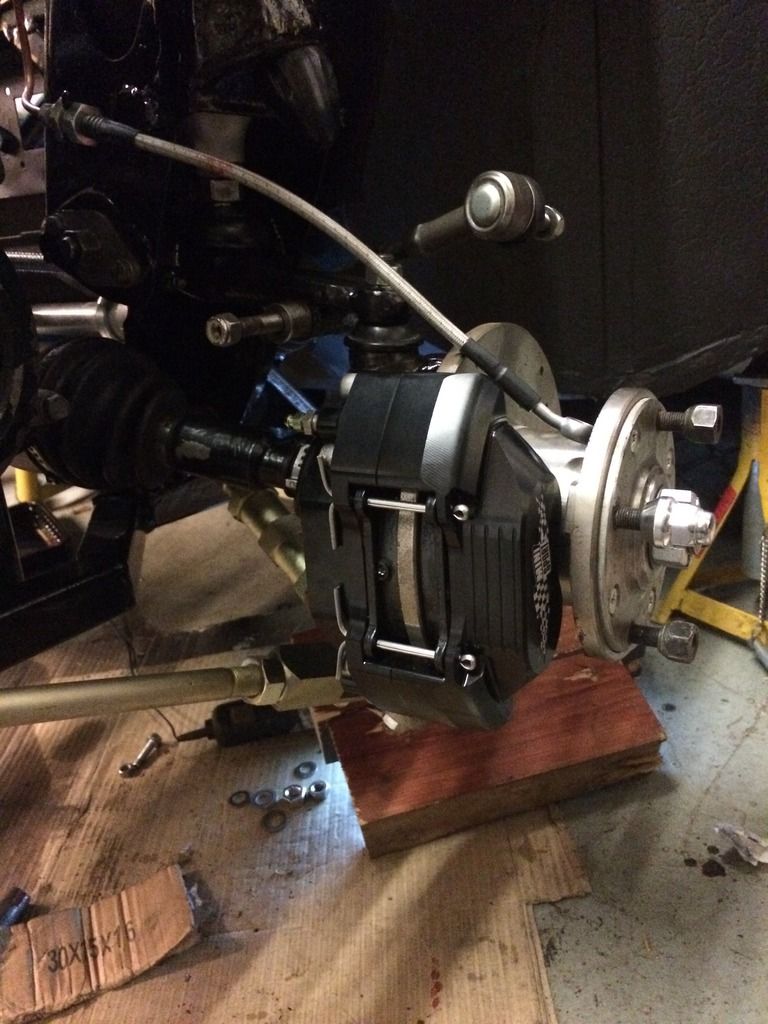

Hubs and rest of suspension components on.

Got the calipers on but got given a wrong banjo bolt when I had my lines made up so can't fit that side until I get another. They are the minisport alloy 4 pots.

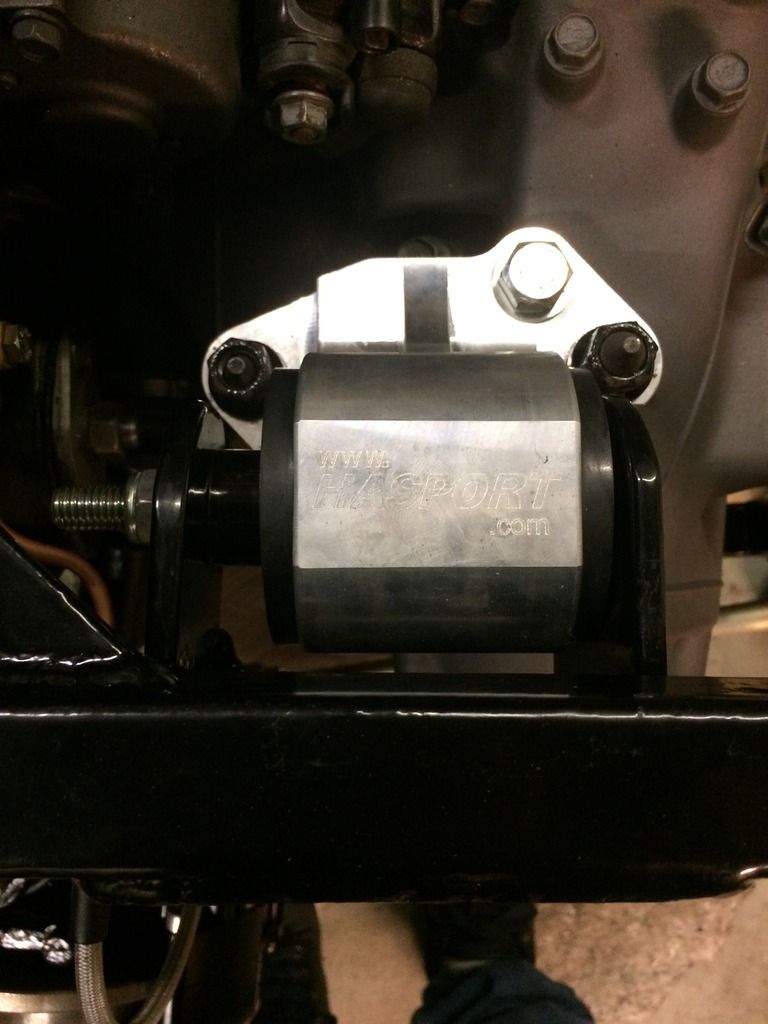

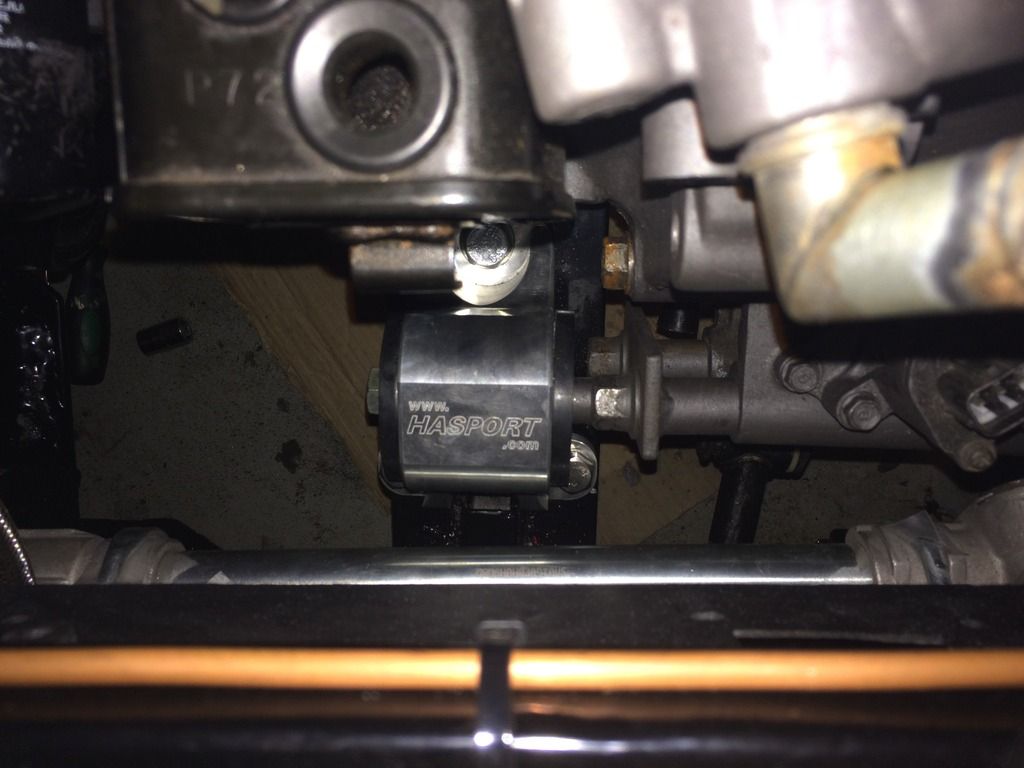

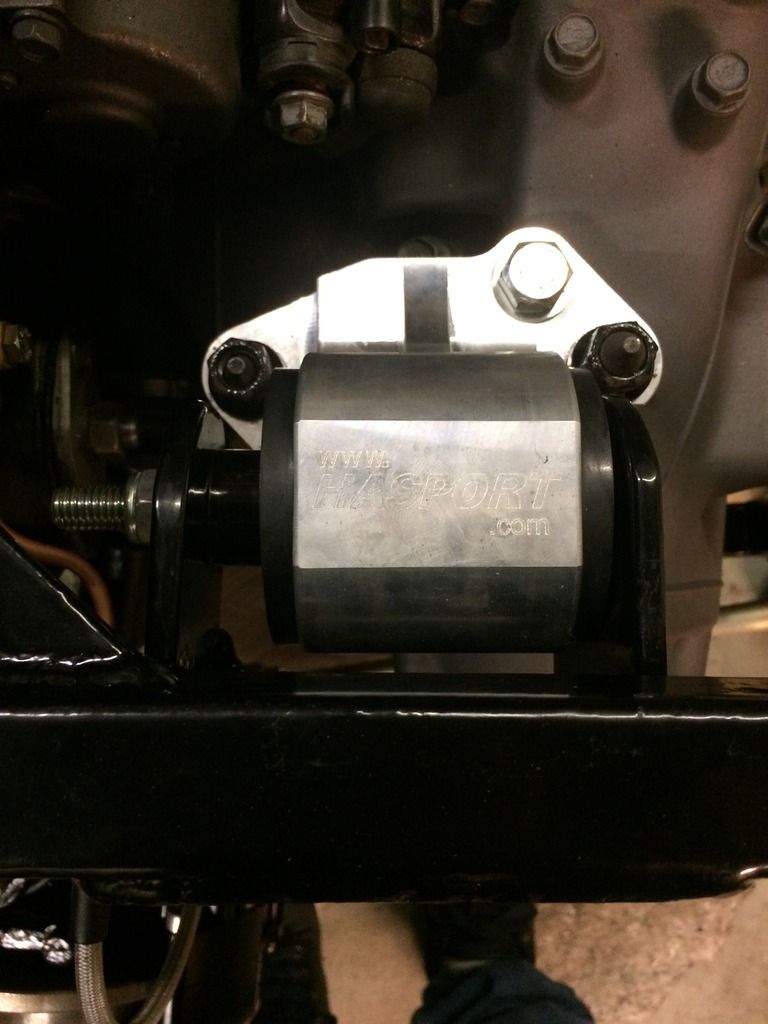

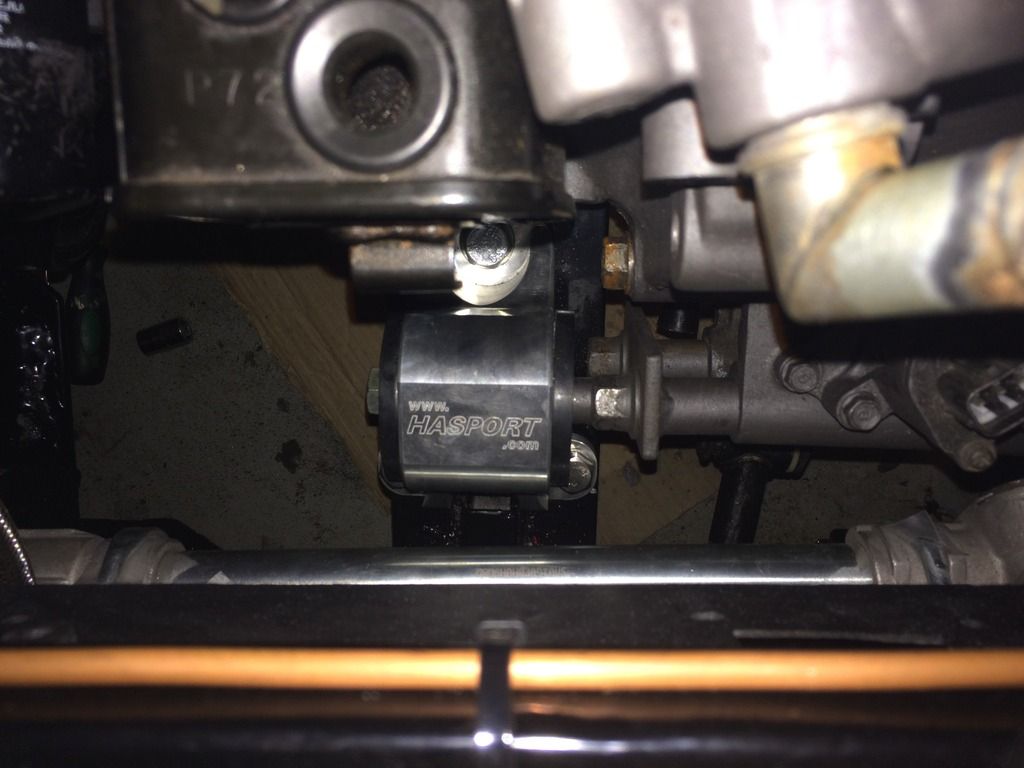

Whilst at work also made some spacers on the lathe for the engine mounts.

Rear mount on.

Then started on the gear linkage. As mine is a 1973 it does have a narrower tunnel so space for the linkage and exhaust is going to be limited. So wanted the linkage to sit to the one side of the tunnel to leave as much room as possible for the exhaust. This did require cutting the floor out a little more.

Also to leave even more room I decided to mount the shifter unit on top on the floor rather than underneath.

Then made sure that the stick was going to be upright while in neutral before I made the rod.

Rods cut to length and tacked in position. Managed to go through all the gears without any drama. Result!!!

All welded up. Just need a kick of paint. Also bought a double bend short shifter.

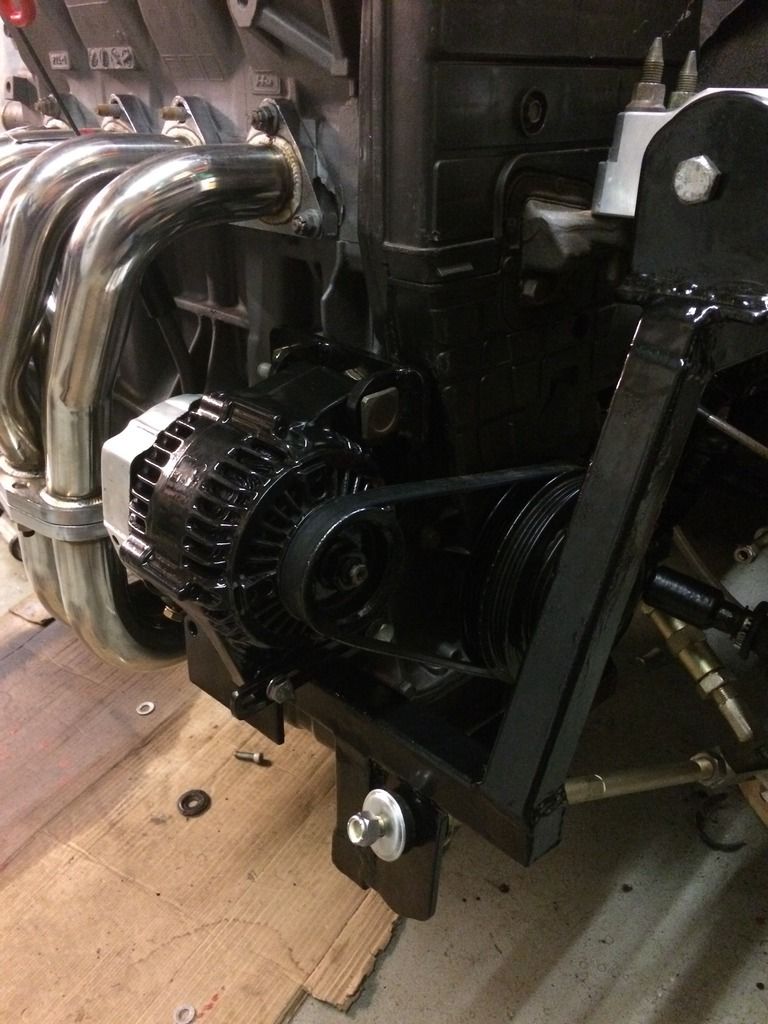

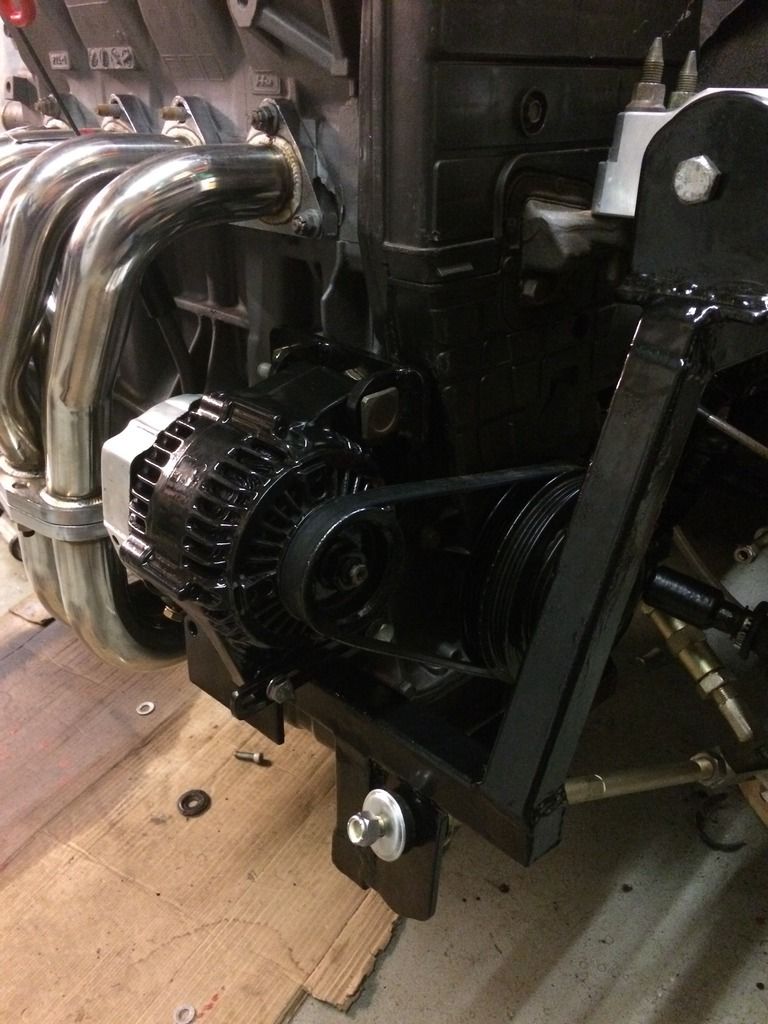

Threw the alternator on. Bracket works a treat. Very happy with it.

Now while waiting for some parts I decided I might as well strip the cam cover. So got some nitromors and had a crack at it.

Gloved up and covered the cover in it. Lovely stuff I must say.

And after applying a load more. About 40 mins later I was left with this.......

Exactly the bloody same!!!!! I followed the instructions down to the letter. Had no effect what so ever!! Couldn't understand why it hadn't worked. So just ended up getting it blasted.

Before I could get the inlet manifold on I needed to get the engine loom on and all connected up. But this needed a tidy, so purchased some braided sleeving which is split so can just be slipped over the loom. Looks great and saves taking any plugs off.

End result.

In position and fed through the bulkhead.

Finally managed to get the inlet on. I did need to replace the studs for some longer ones as I'm using a tegiwa thermal insulating gasket which is quite thick.

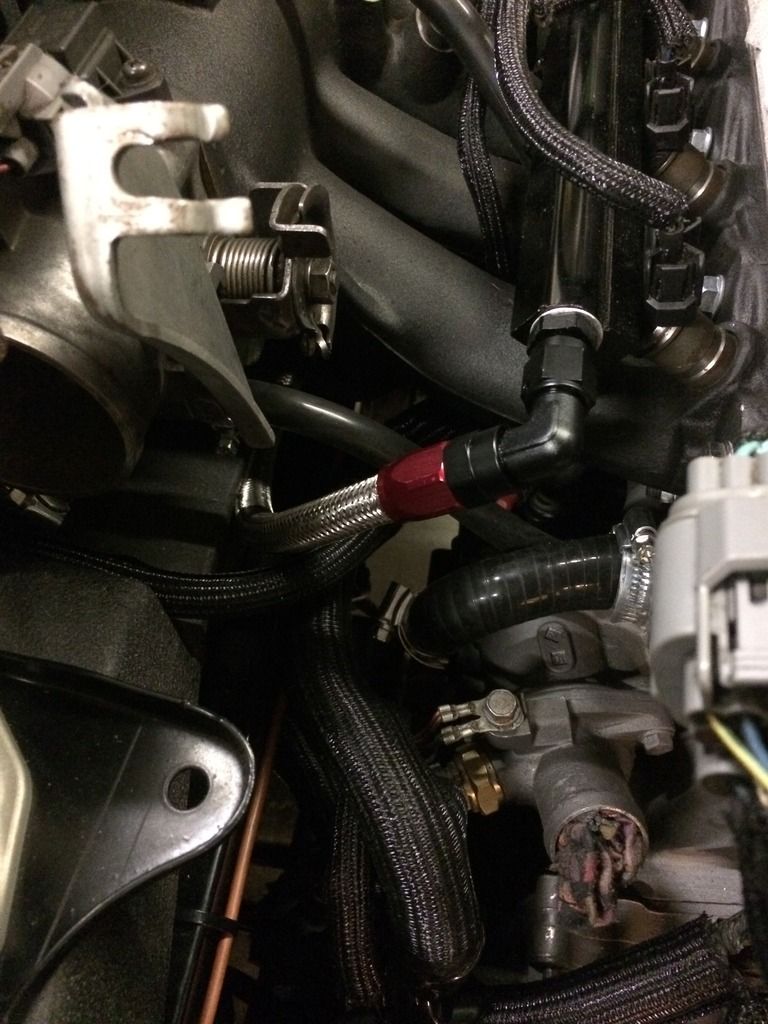

Starting to get crowded in there now.

Happy with how it's looking though. Next need to fit the gear linkage back on as I've repainted around where I cut the floor and also made a plate to blank off the rest of the original selector hole.

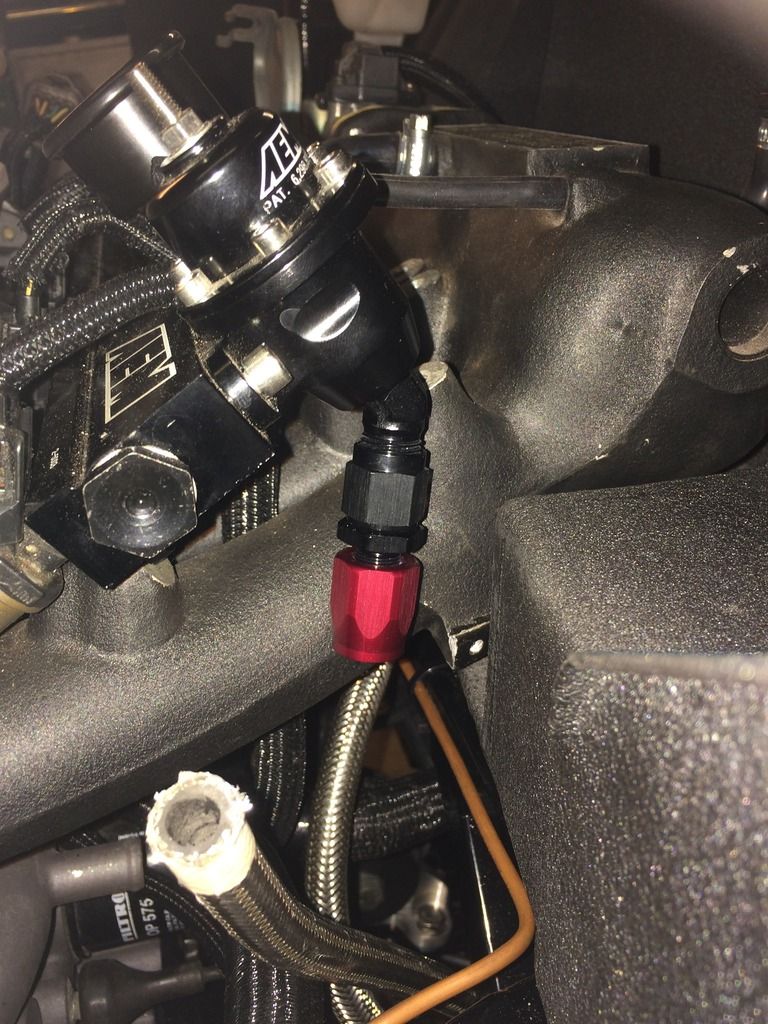

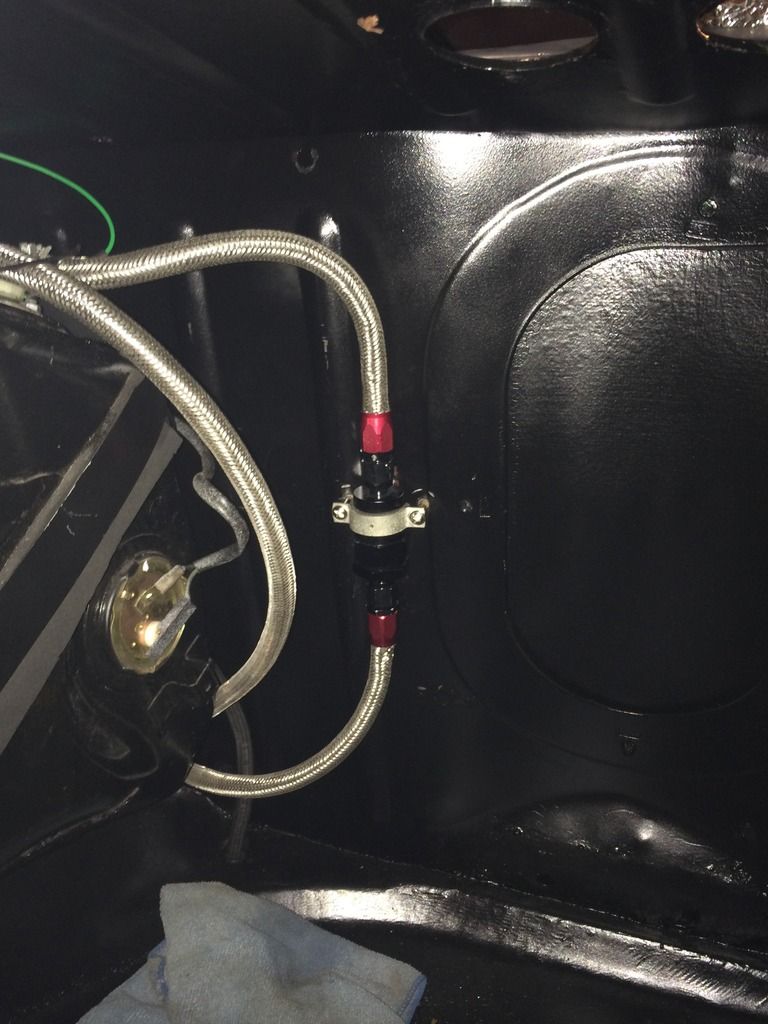

Fit the fuel lines to the rail using braided hose and anodised fittings.

And then on to the wiring!! Dreading it if I'm honest. I have the mini loom which looks to be all labelled up ( I didn't remove it myself) and is in good nick. Then go through the Honda loom again to double check and maybe shorten. Finally try and mate them together. Sounds easy right?!?!?!?!