Penny The Pickup

#181

Posted 10 July 2013 - 09:37 AM

#182

Posted 10 July 2013 - 01:09 PM

#183

Posted 10 July 2013 - 05:44 PM

i have had this problem before and had to weld it as a tempory fix but i wouldnt recommend it as is a pain in the ass to remove after

Dan

#184

Posted 13 July 2013 - 07:41 PM

Maybe an update tomorrow, does it matter what way I have the fuel pump, I know they only flow one way but could I have it upside down ? Thanks

Robbie

#185

Posted 16 July 2013 - 08:55 PM

#186

Posted 16 July 2013 - 09:12 PM

looks superb this does excellent build and nice and clean.

#187

Posted 17 July 2013 - 07:41 PM

really like the project build on this, looks great! on a side note, does the pickup use just a standard saloon rear subframe?

#188

Posted 17 July 2013 - 08:32 PM

yeah use the same rear subframe as a saloon

#189

Posted 17 July 2013 - 08:40 PM

were you the guy in minispeed the other week, who had to go and sit in his car to decide wether or not you wanted to buy the more expensive item or the cheaper ones, while i was buying gaskets etc???

YetI

#190

Posted 17 July 2013 - 11:22 PM

#191

Posted 28 July 2013 - 10:23 AM

so first things first i decided to attack the engine bay ! so i went to halfords brought a wire wheel brush to go on my grinder 2.5 litres of red oxide paint from tool station for £8.74 and some white primer paint.

yesterday i started to attack it! mwahah ! rust here i come ! >

The first job i had to do was to remove eveything from the engine bay, main problem being the old master cylinder was still on and wouldnt budge, after a quick shout on here i was given the awnser and it was all resolved, clevis pins out, pedals out, cylinders out. i then started to sand and after about 1 hours of grinding (sanding) i had this.

majoraty done but i had to get under the scuttle with sand paper and my hand !LONG !

this is the state it was in, i sanded down everything so there was no surface rust and i then used a halfords paint preporation wipe to get ready for the Red oxide paint.

i no its running down the undersealer, but i will redo this.

whilst the paint was drying i tidyed out the cabin, which was full of paper shreddings due to the mouse that had made its home in it.

so i managed to take out the seat belts, that is it, i came up for a coffee and got writing on here, so i will go down now finish of the cabin, and then prime the bay for tommorow,

should i do 2 coats of red oxide ????

Cheers Robbie

I wasn't to sure what primer to use on the bare metal on my Clubby, would you recommend the red oxide and where's the best place to get it? Fantastic build by the way :)

Edited by littlenelly69, 28 July 2013 - 10:34 AM.

#192

Posted 28 July 2013 - 10:36 AM

Really annoying day today, went to fit the handbrake it's and the wrong Clevis pins too fat do though ill fit the accelerator pedal and snapped off one of the studs ! Very anoyed either have to take the subframe out or just weld the pedal plate on to the snapped stud .....

When this happens to us, we just use a punch and knock the remaining bit of stud out (need to drop the subframe) as the studs are pressed in, not welded, then knock in a new stud :) hope this helps!

#193

Posted 19 August 2013 - 08:48 PM

Got these goodies from swiftune

Massive news I GOT ENGAGED !!!!

So that's what 700£ looks like in mini bits :-( wanted more for the money lol

So far so good !

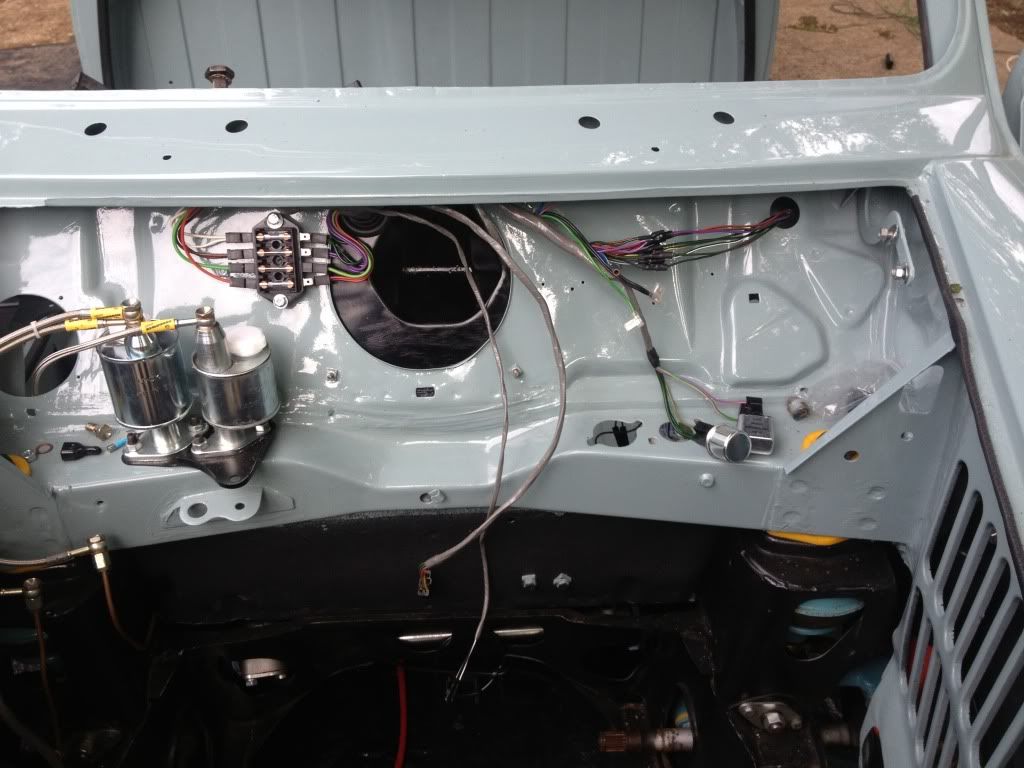

80% of my wiring is now done and complete, also my beautiful rocker cover has failed me, it doesn't clear the alloy inlet manifold......... What a shame time for a shines steel maniflow on that does allow clearance

Thanks and questions if u notice anything wrong please let me know thanks

#194

Posted 20 August 2013 - 05:49 AM

Bloody hell, you'll have no money now if your planning a wedding!

ours just cost us (my in-laws) £25k and that was budgeted and kept cheap!

Just tell her, 'after the mini is finished, we'll start planning it'

and dont let her make you sell it! hahaha

the pick up looks fantastic though!

#195

Posted 20 August 2013 - 10:31 AM

Great build, the pick up looks class.

dominicdee: You must be mad spending £25k getting married!!! Ours was £6.5k and £5k of that was the honeymoon lol.

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users