Mini Virgin Rebuild Of 83 Mayfair.

#301

Posted 17 November 2011 - 07:49 PM

#302

Posted 17 November 2011 - 07:56 PM

#303

Posted 17 November 2011 - 09:27 PM

#304

Posted 20 November 2011 - 06:09 PM

#305

Posted 24 November 2011 - 03:42 PM

Been a little lazy recently but done a couple of things including rust removal and waxoiling. Before shots are of rust on the next end to do as forgot to do before pics, but the rust is the same.

Before

after

before

after

before

after

Not too bad and the other end is in as I type. When all done I will wire brush to remove all other crap, kurust and paint after a little patch.

Then I decided to get some waxoiling done in the sill and valance closer sections. Got some clear stuff, a 5 litre sprayer and a piece of tube I had over and made a high pressure sprayer. Not perfect but did the job fine.

Got spraying away, in the box sections that I have at the moment including the cross member in the cab. Think I over did it a little though !!

Still, all cleaned up and better protected than before, ready for the big chill if it is comming this year lol

Stink of waxoil now, another telling off from Jan, doh !!

Graham

Edited by grahama, 24 November 2011 - 03:46 PM.

#306

Posted 25 November 2011 - 10:40 PM

#307

Posted 26 November 2011 - 04:06 PM

As always Graham you impress!!

My best wishes to you

Hugh

#308

Posted 26 November 2011 - 04:11 PM

Well done on the project graham keep it up!

#309

Posted 26 November 2011 - 06:56 PM

Hinge bolts drilled out today too by my friend with a workshop / engineering shop in his garage, so doors on soon for final front end fit.

Graham

#310

Posted 27 December 2011 - 05:17 PM

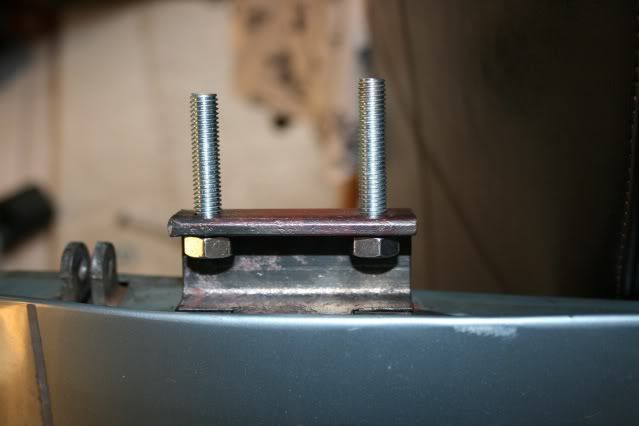

Not been doing much really but a little update. I have been off work for a few weeks recently due to leave blocks, but the weather has been awful, so no chance of work outside. I had my hinges sorted by a friend last time I was working and this was the result.

The nuts are fine but foul on the door skin, so once welded up I will grind that side down so the door opens properly.

I turned my attention to the engine while inside and stripped and checked the rocker from the head I got and all seem fine.

Also took this oil switch off for a check, not sure what it does but it looks fine.

So then the engine block was up for a little tlc and went from...

to...

Unfortunately Matt didn't like it and I am having to re do it in the blue the car will be eventually, enamel on order !! However I am sticking with these for a little colour on the outside.

I continued with the engine bits as I got a rebuild kit from South Lakes minis last week, bearings, seals, gaskets, core plugs, timing bits and thought I'd better clean up the rest of the engine stuff. Pistons were a little coked up so I stripped and cleaned them all up.

Also did the rest of the head bits, springs and collets, the valves and head are at the machine shop for a clean and new valve guides as two sets were too worn to carry on with. Getting all new guides, recut seats and lapping of valves for £70, not too bad.

Then as I was taking the last ring off the last piston I broke the oil ring spacer

A very nice man, Sledgehammer, is sending me some through, but I am still trying to decide if I am better changing the lot for a new set even though they looked fine to the macine shop. Will think about that one for a bit.

Carry on...

#311

Posted 27 December 2011 - 05:30 PM

Glad to see you're moving on with this.

Can you drop me a PM please with the name etc of the machine shop you have used. The 1275 I have in the garage is getting a lonely and I feel the need for some TLC to be sent in its direction.

Cheers

Steve

#312

Posted 27 December 2011 - 05:41 PM

Put the hinges on doors and trial fitted, not too bad but the curve on the bottom still made them stick out too much for me. Thinking of re skinning them and fiddling about with the frame to get them tucked in at the bottom.

I have been emailing Neil, Project Erm, for advice and he has suggested things like slotting the hinge holes to pull the doors in at the bottom. Did that and worked fine but not totally and a door seal was very pinched .

Will have to let the hinge out a little so some fettling coming up next year. Same with the front end as today the weather was good enough to try and set the front end up with some self tappers and get it moving again.

OS side went ok, gaps not as good as I would have liked but will have to do as don't want to butcher the panels too much, already dented the wing !! There is a gap between the wing and the scuttle which I presume the sealer takes up, but will try to close up from underneath before that stage.

NS less favourable and some butchery required..

Can't get them to close up at the A panel join without pulling the wing 'in' and looking odd so will cut a piece in to help the join. Overall ok, but again scuttle join not brilliant, c'est la vie !!

Put the bonnet on and very tight at the front so will be messing about with that too !!

Not a big problem and tried the original bonnet too but that's tight too so things have moved slightly during repairs. However all will be right in the end and as long as it looks right then it will be fine id the bonnet is cut about a bit !!

Still enjoying it, but especially the engine bits at the mo,

Graham

#313

Posted 27 December 2011 - 05:44 PM

I used Dunright in warrington on an industrial estate near Bank Quay station. Old fella with all the gear, very genuire and seems to know his stuff. I have found him very reasonable and talks through what needs doing, not in a way that you feel you are getting ripped off.

Graham

#314

Posted 27 December 2011 - 05:52 PM

Hi Steve,

I used Dunright in warrington on an industrial estate near Bank Quay station. Old fella with all the gear, very genuire and seems to know his stuff. I have found him very reasonable and talks through what needs doing, not in a way that you feel you are getting ripped off.

Graham

Thanks Graham

Much appreciated

Regards

Steve

#315

Posted 27 December 2011 - 08:33 PM

I have read this thread a couple of times now and the work is great. Really inspiring. I used to live in Warrington and never knew of that place :/ still - live and learn i suppose.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users