Mini Virgin Rebuild Of 83 Mayfair.

#316

Posted 27 December 2011 - 08:34 PM

What a brave man you are on my page!! I would love to see you show Jan your post! Its amazing what courage we have outside of the wife's notice!

All the best, hope you are having a great festive season.

Hugh

#317

Posted 28 December 2011 - 08:41 PM

#318

Posted 31 December 2011 - 02:38 AM

#319

Posted 02 January 2012 - 06:10 PM

small update as usual at the moment !! Engine on hold till everything opens and I get a tool to deglaze the cylinders and some rings for the one I bust. However I did get the head fitted with new valve guides and the machine shop recut the seats and lapped the valves in for me, however the cost was £85, so a little more than I was expecting, cost of the guides, but done nicely.

Would liked to have done these myself but I don't have the guide fitting equipment and cutting the seats back in meant it was way too much for me and the grinder !!

Next was the long standing date with my rear subframe. Got the rust off it a while ago and got it out to be greeted by more surface rust, that will teach me to leave it too long in the shed !! Anywat wire wheeled and brushed it back to a nice condition and set about fixing it up.

Had to drill out a nut on removal and there was only a little rot so cut it out. Made a piece and welded it in and positioned a camber bracket to align the new nut.

All welded up and ground back it got a severe kurusting !!

Had to look at the gearbox as Carlos is getting back in the lead so out it came from under the stairs. Initially I was told it was crunching into 2nd gear and saw some grooves on the gears. My heart sank as I thought they were crunching markes but turned out to be marks put on to identify the gears. So here goes, my first look into gearboxes !!

Start point was to remove the roller bearing, bloody hell no bearing puller what a crappy hour that was. Yes you guessed it, bust it right near the end !

None of the fancy stuff to get the input end tight nut off either so it was up to Matt to help..

Just enough weight on there with the block and Matt, came off quite easily too I thought after reading about people's scaffold bars and long pole antics, socket bar and a ring spanner for leverage and off it came.

Stripped the box of all the bolts to make cleaning it up later easier and had a look at the gears.

See what I mean about the grooves!! Guessworks has looked at them and says they are fine so that will do me. Will change the balk rings when I redo and hopefully that will be all. Just waiting for a big socket to undo the other tight nut on the diff end.

That's all for now, small but interesting, for me anyway !!

Graham

Edited by grahama, 02 January 2012 - 06:12 PM.

#320

Posted 02 January 2012 - 06:27 PM

Edited by minimuk, 02 January 2012 - 06:29 PM.

#321

Posted 02 January 2012 - 06:36 PM

cant beleive how long its been since i last commented on this

you and hugh are racing ahead of me now but at least i can keep an eye on this to help me out, projects coming along really well though!

hope the new year brings you luck

Ben

#322

Posted 02 January 2012 - 07:28 PM

Graham. make sure you hide the weld to the subframe. I gather there are new MOT rules in which welding repairs to a subframe isn't permitted anymore. That and lazyness made me buy a subframe (as my Xmas present from Anne). Your welding is so good you can easily do an invisible repair.

Glad I'm not touching my engine!

All the best

Hugh

#323

Posted 02 January 2012 - 08:46 PM

Good luck.

#324

Posted 03 January 2012 - 03:03 PM

#325

Posted 03 January 2012 - 07:44 PM

#326

Posted 03 January 2012 - 07:59 PM

#327

Posted 08 January 2012 - 08:08 PM

been inside thinking how to undo the third motion box nut as it seemed tighter than the other end. In the end I took it into work and jammed it under out weights bench, piled on loads of weights and with an extension bar it undid, just like that !!!

Stripped the diff and cleaned it up into it's component parts but stopped short of splitting the crown wheel bit as it looked fine so why create yet more work.

All nice and clean, wd40 to protect it ubtil the rebuild. Now, after the two tight nuts were moved I removed the lay gear and the reverse gear to clean and inspect, came up fine, shaft ok, lay gears ok, reverse gear fine. To me that is, have asked in problems for a more expert view.

Getting the lay gear and reverse gear and shaft out was just a case of undoing a few nuts and tapping the shafts out. The bearings on the main shaft were the next problem. I also took out the oil strainer and sump plug for a clean. The strainer will be replaced with a centre oil pickup but I was amazed with how clean the strainer was. Has all my oil burnt off leaning no work for the strainer to do, I don't know but the sump plug had some crap clinging to it.

Mmmmmmmm bearings on the main shaft !! I decided to make a slide hammer with a thread attachment out of the old nut to pull it off the main shaft.

Used some taped together sockets for the weight on the slider and after two or three slams, the bearing popped off, easy !! Hugh, I have some Scottish in me as too tight to buy a tool for 1 job, lol. After this I had read that you knock the 3rd motion/diff end to move the gears over and create a space for a collet thing to push the other bearing off, so I made some out of some hard plastic I had.

I knocked the shaft back towards the diff end and the spacers, filling the gap as shown, pushed the bearing out. Had a couple of problems but not major, the very start of the thread on the input end came off as I couldn't screw my tool on far enough and I may have broken the double roller bearing as it has a split in, but the thread will be fine with a new nut and am finding out about the bearing split.

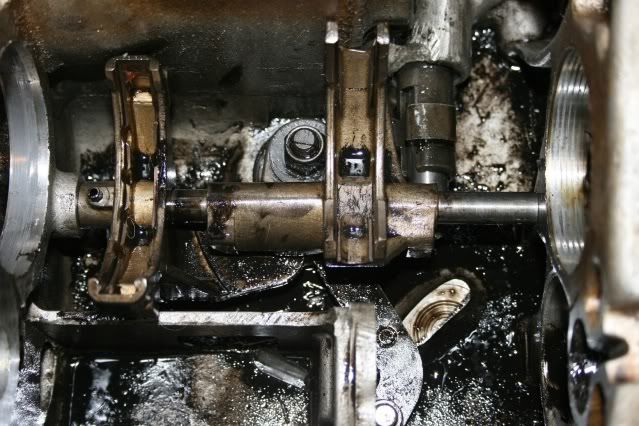

Anyway, after a full day of making tools, City getting shafted by the Referee in the FA Cup, and Jan scouling at me for not starting the back room decorating I was left with this...

Result !!

Just got to clean it up, paint it and put it all back together !!

Graham

Edited by grahama, 08 January 2012 - 08:13 PM.

#328

Posted 08 January 2012 - 08:29 PM

I found that the pin on the left of your bottom picture hits the bottom of the casing but is far enough through so that it's no longer in the shaft!

#329

Posted 08 January 2012 - 08:34 PM

#330

Posted 08 January 2012 - 08:37 PM

Edited by Carlos W, 08 January 2012 - 08:37 PM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users