Hi,

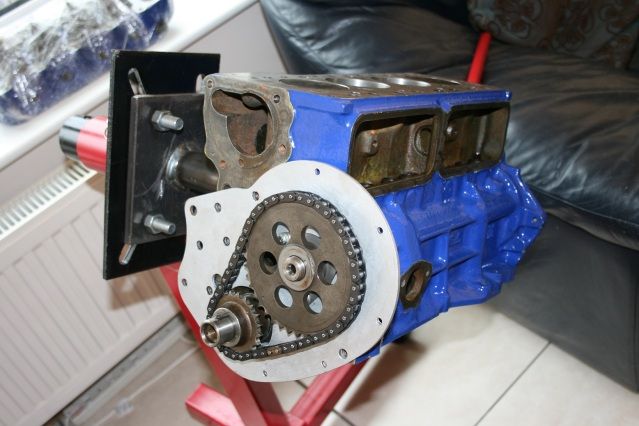

been at it again, inside stuff and outside. Will do the inside first as shorter !! Got the engine to a near finished state apart from ancilaries.

All timed up, torqued up and rerady for the gearbox which is up to here...

Got the circlip back in with a little persuasion from my less than adequate tool set and tried the gears using the temporary gear changer, an allen key. It was way too tight, all gears stiff, so I pulled the first motion shaft onto the back of the circlip using my slide tool from a few pages back and they freed up nicely. I have a worry though with the selection of 4th gear. The selector rod moves too far forward and the synchro hub ends up hitting the lay gear. I rang John at Guessworks for some advice and he said it would inprove with the box torqued up properly and with the gearlinkage, so I tried.

Still too much movement, all other gears fine, so may put a modification into the box where the gear stick goes in to stop the rod moving too much. Will have to think about that one though and maybe talk to John again.

"" Just a not for you all, John at Guessworks is a brilliant bloke, lots of free help and tips if thing going a little wrong. I have bought my gearbox bits from him so thought he wouldn't mind, but I think he's like that anyway, great fella and great service ""

Anyway, sun, sun, sun here in Warrington so outside it was, after changing the shower trap for Jan, (kitcken ceiling holed now so another job to finish), but she's happy now !!

I closed the ends of the scuttle to make the closed ends underneath just that, closed, and plopped some weld into the top of the A post holes so all water tight now hopefully.

Yet again, I tried the a panels and wings, sorry for more pics the same, and asked a question in the tech section. Ok fit of driver wing but the a panel was way too far forward, same the pass side, so I had to start fitting again.

As mentioned by Hugh on his thread, releif cuts to the wing helped the fit so I did this too and put some self tappers into the a panels in a better position.

Looking better now, the relief cuts worked to bring the wing down into position along the scuttle gap. I also had to shave some off where both wings met the inner wings to allow for the relief cuts, but this helped out with the bonnet gaps.

On the passenger side the a panel and wing still didn't meet, and when pulled to fit the result was to pull the wing and a panel in and it just didn't look right so I cut a slot to take up the slack.

I used a much practiced technique for the first time, copper strip to bridge gaps for welding and it was a great trick. Never thought it would work as well as it did.

The door gaps ended up like this

and the bonnet side gaps

Very pleased with these, worth another day of fiddling about with the panels. However the bonnet is tight at the back in both corners and will need some adjustment there, but will ask in bodywork section first. But here it is

I had a gap in the scuttle I wanted to fill so set about making a patch, all was going well till the power cut, very rare in sunny Warrington, so out fot tea it was as all we have gas for is heating and the kids turned thier noses up at butties !! This is as far as I got

Well thats all for now, feel like I am getting somewhere for a change !

Graham

Edited by grahama, 20 March 2012 - 09:28 PM.