Mini Virgin Rebuild Of 83 Mayfair.

#541

Posted 26 June 2012 - 09:51 PM

#542

Posted 27 June 2012 - 06:57 PM

were off at last with the spraying part of the project. Stone chip anyway !!

I used UPOL Gravitex in the 1L pots for the scultz gun. I asked in the bodywork section and set my pressure on the ancient compressor to 50 psi.

Quite pleased with the results in the boot, tried there first as a test run. It seemed fine in places ripply but flat in others, not sure why. Took longer to dry than I thought though, touch dry soon enough but the thicker stuff took ages.

I decided to do the rest of the underneath as rain is forecast for tomorrow. Same set up and on it went, deep and crip and not even !! Slathered it on in the important areas, arches, sills, flitces and as much as possible on the floor. I used 5 bottles in total at 5.99 + vat so quite pleased.

I still had some thinner areas which had thicker ripply bits next to thinner 'dryer' areas.

No idea why this happened as I passed over the area in the same sweep, but not the same. Any ideas why??

OOps !! dropped some steel bar fron the spit in the boot so a repair already needed and missed a couple of bits too because of access mainly. Will have to get a rattle can to fill in these bits I think. I masked up some what but still had some over spray onto the body panels I have just etched.

Hopefully when dry it will sand off !! Well chuffed and hopefully no reactions when dry tomorrow, or it's all off !!

Graham

Edited by grahama, 27 June 2012 - 07:09 PM.

#543

Posted 27 June 2012 - 07:36 PM

May I ask why you used stone chip inside the boot ?

Andrew.

#544

Posted 27 June 2012 - 07:43 PM

Just did it as a test area to be honest and it gets a few knocks when in use, it won't be seen too much so not really concearned.

Graham

Edited by grahama, 27 June 2012 - 07:43 PM.

#545

Posted 27 June 2012 - 08:52 PM

You never know if you spend some time with some 80 grit you might get it of.

Andrew

#546

Posted 29 June 2012 - 08:04 PM

Had a look at the stone chip today after it had dried for a day of so and I have had some reaction !! It is around the sill vents and think it is waxoil contamination so will have to wire brush off and re do those bits but no stock at the auto paint shop till Monday. Bit annoyed to be honest but better to fix now than rust later.

So on with a couple of jobs I have been putting off for ages. Getting the petrol tank and bonnet ready for paint.

Petrol tank first and it was surface rusty inside so I went down the low tech route and filled with stones and shook for ages. Lots of rusty powder came out so it did it's job nicely. For some added protection I poured some kurust inthere to give a coating. Will be fitting an inline filter on set up to catch any loose stuff !! So started to strip the tank, full of little rust spots on the outside but solid.

All stripped back to bare metal and etched ready for primer and paint.

Then to the bonnet which I had cut about to get nicer fit and welded back up.

I have ground down the welds on the outside but a skim of filler was required, the inside needed stripping and etching before seam sealing over the weld backs.

It took a while to strip the inside with a wire wheel and flexible 80 grit disc on the grinder but had to resort to a stanley knife blade to get the tight cornets done. Came out nicely though. The front was easier except for the really hard and what seemed flexible paint that kept clogging my strip discs. It was a second hand bonnet so don't know what had been done to it before but off the paint came.

Then the filling, never done it and was dreading it as I hate sanding.

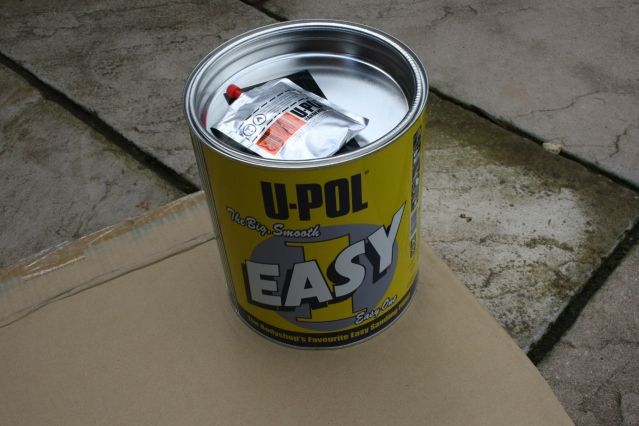

Got the upol easy 1 stuff as it said easy sanding and mixed in the golfball to pea ratio then spread it on, mixed far too much but you learn all the time in the mini game.

Let it go off and sanded with 240 grit wet and dry, easy sand my arse !! Had to resort to 80 grit to make inroads, and yes it was as expected a crap job to do as I thought !! Filled the missed bits, more sanding, and filled again. Came up after a couple of hours with sore fingers and this

Panel wiped it down and etched

Came out nice but there were some imperfections left after etching which I will have to sort and the bonnet pin holes to scrape out.

comming along,

Graham

Edited by grahama, 29 June 2012 - 08:08 PM.

#547

Posted 29 June 2012 - 08:24 PM

Liam

#548

Posted 29 June 2012 - 08:28 PM

#549

Posted 29 June 2012 - 08:55 PM

Edited by minimuk, 29 June 2012 - 08:55 PM.

#550

Posted 29 June 2012 - 09:43 PM

Upol fantastic is a 100 times better.

#551

Posted 29 June 2012 - 09:52 PM

#552

Posted 29 June 2012 - 10:15 PM

You can almost use it as a stopper, its beautiful stuff!!

#553

Posted 29 June 2012 - 10:15 PM

Thanks for that, but what is the difference. Not much to do so will have to stick with it now. As long as it doesn't fall out and takes paint then it will do.

as far as I know, easy sand is for minor little scratches and small one off jobs, as Shifthy states the 'fantastic Upol' is designed for the jobs you are doing, I don't think it will fall out, just the fantastic is easyer to apply and sand/flatten after with 80-240-600grit.

#554

Posted 30 June 2012 - 06:48 PM

Will a da sander rather than using a block and elbow grease be better to get the same result, or are they too rough ??

Graham

#555

Posted 30 June 2012 - 08:37 PM

Ok I see the difference now as it was harder to spread than I thought. However I have to perservere with it now and learn my lesson !! I have only a few bits to do so not too bad.

Will a da sander rather than using a block and elbow grease be better to get the same result, or are they too rough ??

Graham

elbow grease I am afraid is the better choise to flatten the filler, take yr time and feel where you go,machine is not controlable...unless you use one everyday...

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users