Mini Virgin Rebuild Of 83 Mayfair.

#676

Posted 25 September 2012 - 08:39 PM

#677

Posted 27 September 2012 - 02:26 AM

My mini has been sadly neglected for the past 2 months to be honest, shes still working just not had the time to run her, so much so the battery is flat, will get it charged tomorrow

Phil

#678

Posted 27 September 2012 - 05:17 AM

Graham - They also do the proper Fabric Loom Tape as well.

#679

Posted 27 September 2012 - 05:42 PM

Phill, no problem, just let me know when u need it and I will drop it down, you might still have my number but I will pm it you just in case.. The next job now the wiring is hopefully sorted and tested is to test fire the engine. Need a clutch plate, water pump and some expertise first though lol !!! May well be calling on you for the expertise part soon.

Brams, I have some of that tape, arrived yesterday, but was thinking of a non sticky liner to put on first incase I have to replace a wire. The spiral stuff MB suggested could go on first and then wrap it in the tape. More protection the better !

The fusebox, a great idea and have seen this before but too much work extending the loom to fit and sorting blade fuses out. I just cant find all the equipment ratings to get the fusing correct.

Graham

#680

Posted 27 September 2012 - 09:27 PM

No worry about the mag base, as long as its still safe, just the boss at work was asking if I still had it

#681

Posted 09 October 2012 - 06:43 PM

not much progress over the past week or so, but progress is progress so here goes.

The electrical saga continues, with minis I bet you're not surprised, but I am pretty much there now.

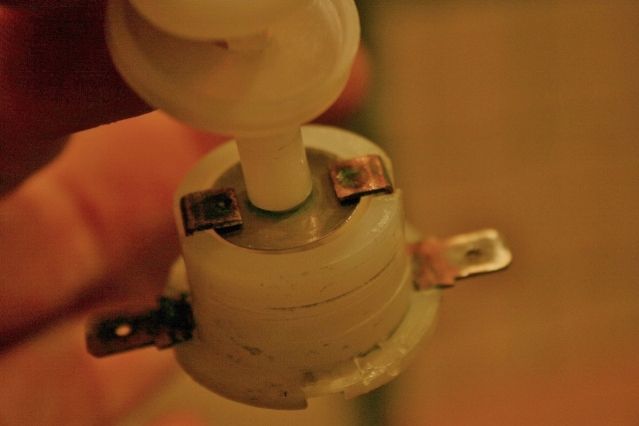

The brake fluid reservoir was not working and the cruddy contacts were the reason. A strip down and sand with wet and dry solved that problem, and at £15 each to replace then I am pleased. The only other thing not working correctly is the petrol sender and I tried to fix it, but it wont send a consistant signal to the binicle so I will have to but one of those, doh !! All the contacts are on between the front and rear loom so just need to fit and protect the junctions. I will use a combination of heat shrink sheilding and self amalgamating tape, which seals onto itself to make a water tight cover.

The wiper motor was working ok, but seemed a little laboured when I was going through the loom so I striped it down into it's component parts, cleaned with white spirit to get the old muck and greaseoff and reassembled, luckily without breaking any bushes or wires, unlike the alternator !!

All re greased and tested I covered it up till I need it. The radiator cowl was next but I have only just got it off.

A bit cruddy and corroded but a good wire brushing and coat of etch soon sorted that out. Will paint tomorrow in the loft 'art studio' !!

I got a break in the rain the other day too, amazing I know for Northern England so I decided to paint the boot as it was the only bit of the inside not finished.

All going well I thought till I uncovered the rear quarter and found the dreaded brown stuff.

Only slight surface rust but I will have some extra prep work to do when I finally get to paint next year. Bit annoyued to be honest but not unexpected, it's only etch primer and it's my own fault for not getting on with it !!!

I have also sorted the wiring for spot lights, stereo system and security and that will be going into the stripped loom when it arrives.

There ya go, a bit more !!

Graham

Edited by grahama, 09 October 2012 - 06:46 PM.

#682

Posted 09 October 2012 - 06:49 PM

Edited by alex-95, 09 October 2012 - 06:49 PM.

#683

Posted 09 October 2012 - 06:50 PM

Hugh

Edited by hughJ, 09 October 2012 - 06:50 PM.

#684

Posted 09 October 2012 - 07:34 PM

looking cracking as always mate! shame about the rust but I'm sure you'll have it sorted in no time.keep up the good work. joe

#685

Posted 12 October 2012 - 05:25 AM

As you may notice this is all test fitted, lock tabs not done up, torque setting not done but it all goes in. Will, if I can get hold of a plastic cup get it on wheels at the weekend, honest, but all hopes of paint have now gone.

You noted it was all temporary here, I hope you have just placed those track rod ends like that (Upside down!) the tapers will not fit correctly!

Sure you have it covered..... !

#686

Posted 12 October 2012 - 07:03 PM

Graham

#687

Posted 12 October 2012 - 08:38 PM

I had no idea that they were upside down, thanks. I put them on that way as it was the only way the rack ends looked right. When on the other way up the ends of the rack seem to point down which seems wrong ??? Is this right ???

Graham

it only seems like they're pointing down cause the suspension is hanging, they work out about level when the car is on its wheels so thats in from underneath and nut on top

#688

Posted 12 October 2012 - 09:39 PM

Graham

#689

Posted 13 October 2012 - 07:45 AM

#690

Posted 13 October 2012 - 10:13 AM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users