who made up ur door cards?went and picked up my door cards

well happy with them, same theme as the seats, double silver stitching and silver piping

will look great when i finally fit them

My First Wee Project :d

#31

Posted 30 May 2011 - 10:30 PM

#32

Posted 03 June 2011 - 01:58 PM

#33

Posted 05 June 2011 - 06:41 PM

im thinking of making it with oak since its a nicer shade and lining the pocket areas with black leatherette, no wee cupboard type things

opinions please on this

thanks, Adam

#34

Posted 10 June 2011 - 04:05 PM

still got frig all done on the actual mini but my mate gave me a call on wednesday and told me there was some mini parts at the local auction, went down to view and see what there was and next day went straight down at the start of the auction to try and get it

3 new brake cylinder things

2 funny lookin foot pedals (i doubt i will use these at all)

1 new door seal, i dont know if it genuine or not

1 complete internal release grill which i will be cleaning up and selling

4 new tie bar bushes:

1 newish looking choke cable:

1 brand new full rear light set up for the rh side i think, includes bulbs, wiring seals etc

a pair of brand new headlamp peaks, dont know if i will use these yet:

and a brand new tacho metre, i definately wont use this because i dont even know if any minis have them

and i got all this for £11.80

very happy with this

Adam

Edited by Mini Mad Drakeley, 10 June 2011 - 04:06 PM.

#35

Posted 18 July 2011 - 09:06 AM

itsjust a rev gauge and some did and others just put them on

keep up the good work

#36

Posted 02 August 2011 - 08:32 PM

not really got alot done cus ive been going out wayyy to much lately but im starting to crack o with it now

decided to spray up the fuel tank as one of the many wee jobs ive been intending to do and i think it turned up quite well

got the OS sill repair panel welded on

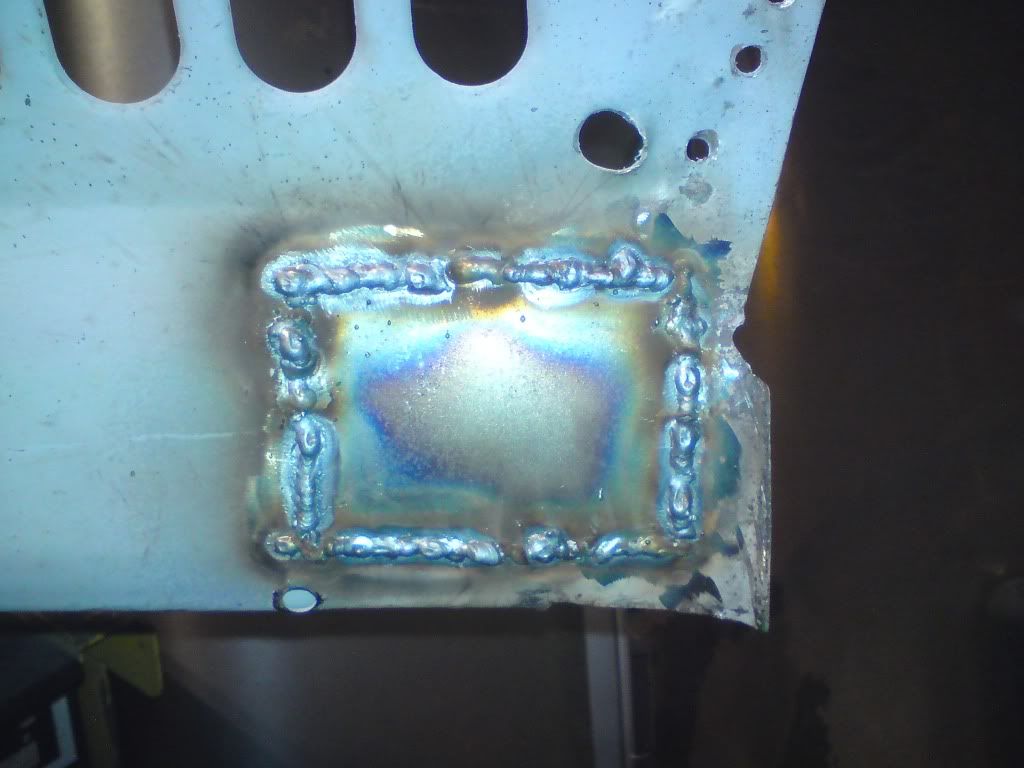

got the wee corner bit of the boot floor welded on aswell, dont know the exact name

we then made a rear quarter patch and welded it on, tee is bringing his shrinking hammer to get rid of any distortion

took all the boot area down to bare metal and kurusted and primered it

spent a day trying to fix the welder i had been lent and now it works brilliantly so i cracked on and ive started to repair the bonnet bit that the lip welds onto, going well so far and only a little bit left to do

all comments welcome,

thanks, Adam

#37

Posted 08 August 2011 - 09:10 PM

just a tiny bit of work left to do on the bonnet, 1 small patch at the back lip and to weld on the chrome strip lip

the main shell has all the patchwork now done on it :D just got the front end and the rear valance and closing panels to weld on and grind down all the welds :)

the last 2 patches

now for the bad news though, we started to work on the drivers side door which was just meant to be a tiny patch in the bottom...

scraped away the seam sealer to find that although the skin had been replaced at some point recently, the frame hadnt been repaired and the skin wasnt even welded on so we took the skin off and we can re-use it luckily :) and work has already been started to the frame by fixing the corners and itl be finished on thursday

we decided after looking at this door that we would have a look at the other which is alot worse, now that i actually know how to tell filler i took 1 look and thought ohh ****, the skin was shot so ive already got a new one and the frame is alot worse but we are going to fix it although it will take alot more patchwork and effort

thanks, Adam

Edited by Mini Mad Drakeley, 08 August 2011 - 09:31 PM.

#38

Posted 11 August 2011 - 10:23 PM

the door is ready to be welded back together tomorrow cus both the skin and the frame were taken down to bare metal, rust treated, zinc primed, bit of etch and a coat of red oxide on the frame and il do another tomorrow morning and i stone chipped the skin because apparently it gets rid of some of the tin sound when you knock it or something

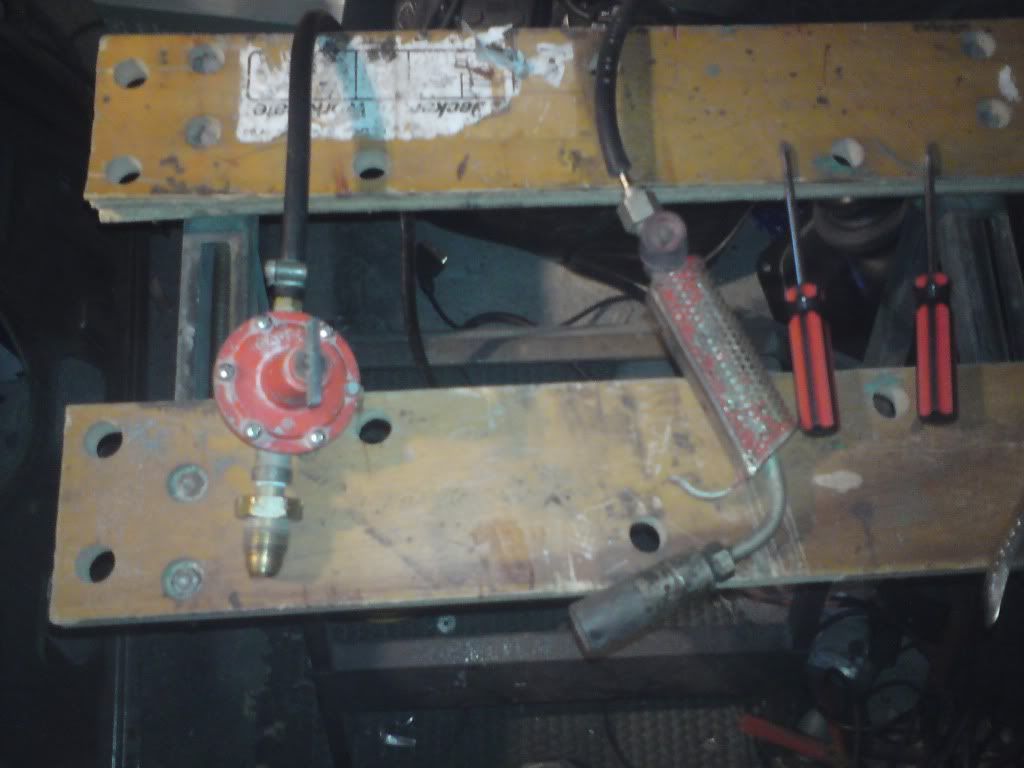

borrowed a couple of helpful things off my neighbour who doesnt need them

a trolley type thing that the shell is now sitting on so i can move the shell around and out of the way now no problem and the shell is still very stable on it

and a wee toy im really looking forward to testing

what i hope is a miniature flame thrower to melt away all the old underseal from the bottom instead of using a heat gun

all comments welcome, Adam

#39

Posted 12 August 2011 - 10:07 AM

#40

Posted 12 August 2011 - 11:56 AM

#41

Posted 12 August 2011 - 12:14 PM

Matt

#42

Posted 12 August 2011 - 04:29 PM

heres a pic of a wheel from the powdercoated, in the dipped bit in the middle the paint isnt very good so i may either take them back and get them to do a proper job or have a go at fixing the pits

what do yous think i should do if you can see the pits at all? i can get a picture that shows them up more

on the good news we got the drivers side door done

i set the bonnet on and it almost looks like a car now:)

i should have more updates tonight when i get the boot lid done and finish the bonnet

all comments welcome, Adam

#43

Posted 12 August 2011 - 07:21 PM

Hugh

#44

Posted 15 August 2011 - 09:38 PM

may weld the tip of a nail to the centre of the dent and try to pull it out and shrink it down if the metal has been stretched, hopefully that would work

on the plus side though it stopped raining for a day so i wheeled the shell out and set up the blow torch and got the scraper and wire brush and done the inner wings and the sills and got a mate to help me roll it onto the side so the underside could be done

1st time hes been outside in over a year

made life alot easier haha

not the most recent picture but its all taken back now to bare metal and theres no underseal left just lots of surface rust and welds but started on those today before it started raining

all comments welcome, Adam

Edited by Mini Mad Drakeley, 15 August 2011 - 09:39 PM.

#45

Posted 19 August 2011 - 10:04 PM

i had the shell outside again on its side to get some welds ground down and get everything kurusted and got half of the underneath etch primed, need another dry day to get the underside finished but grinding down some of the 1st welds i did made me realise how bad they actually were, il be cutting out the bad bits and re-welding in smaller patches to get decent metal to weld to, already did the inner wing and its alot better now

got the welds on the inner wings ground down and then everything kurusted and etched, looks alot better now

il be taking the red oxide off this side cus i got some other primer i want on underneath the red oxide

i then started on the quite rotten door frame, its proving to be a bit of a pain and not just because i got burnt several times

i had to repair some of the rounded corner bit on the frame which turned out quite well i think and then i had to draw up a new corner and trim it to the right size because the original corner had completely rotted away but its a good fit with the new door skin now though

got the other corner done which wasnt quite as bad

as i left the door and i will hopefully finish fixing the frame tomorrow night or on sunday

all comments welcome, Adam

Edited by Mini Mad Drakeley, 19 August 2011 - 10:21 PM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users