i had envisaged

my front bumper/ bodykit was damaged in the same crash that the rear was ripped off, so maybe i could join from the bottom of the bumper under the engine to clean that up.

Posted 16 June 2007 - 10:11 PM

Posted 16 June 2007 - 10:28 PM

Posted 16 June 2007 - 10:35 PM

Posted 16 June 2007 - 10:50 PM

Posted 16 June 2007 - 10:55 PM

Edited by lvm18, 16 June 2007 - 11:05 PM.

Posted 17 June 2007 - 12:18 AM

Here's mine at riv run after the crash....

after some photoshopping to clean up the Damage...

and a photoshop with a diffuser....

if only you could press a print button and actually make it happen!!!!!

Posted 17 June 2007 - 02:47 AM

Posted 17 June 2007 - 10:07 AM

Don't think you want to pull up the tray too steeply at the rear or you're likely to just get turbulence.

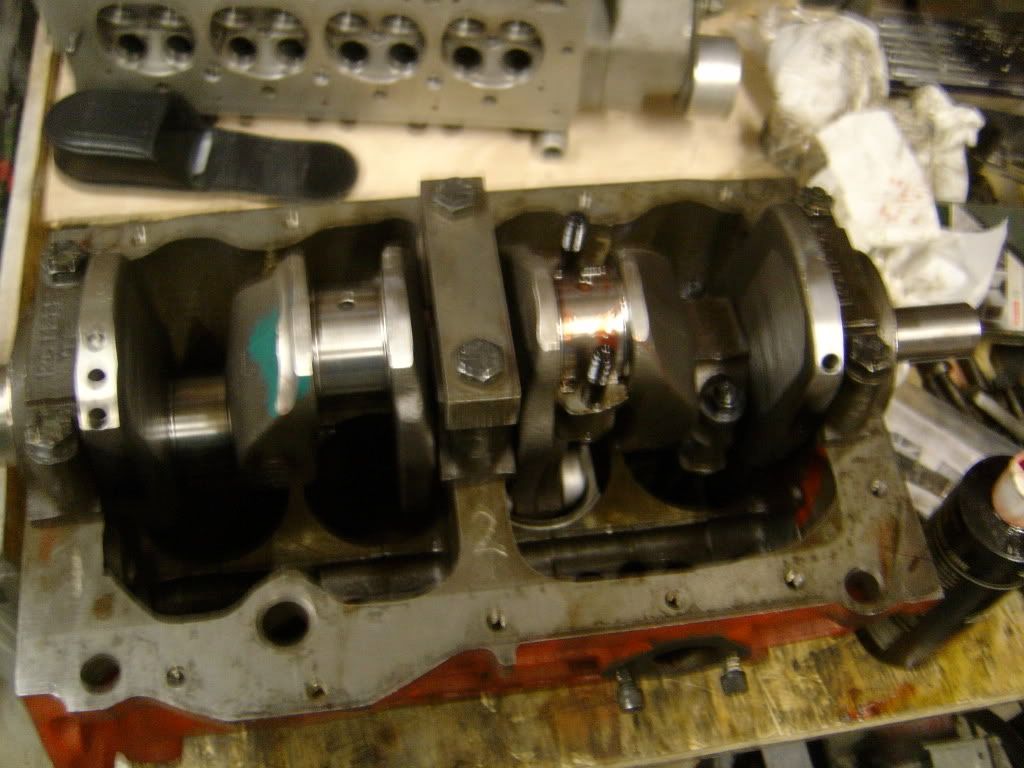

I have a Midas - the earlier Mini based one. It's also in dry dock as it slowly becomes Turbofied.

Be interested in any tips on Megajolt as that'll be the next bit to sort - where did you get your trigger wheel sorted?

I found a 1300 Montego radiator goes in really tidily as the fan's on the other side, but it has pipes at both ends so might be a squeeze plumbing a 16v head. The 1600 and 2.0L ones would fit well too as they just get longer.

I have a SD1 steering column in mine using the bottom 3 or 4 inches of the mini's to couple to the rack. It clears the pedals nicely, is adjustable and gives a better driving position.

I bought my Midas with a really dodgy MOT from a car dealers - I was curious but wasn't convinced it would make a practical car. It had a clapped out 998 lump with no oil pressure but it would still just touch a ton and cornered like you wouldn't believe even though there was inches of play in the suspension. Best shock was stripping it to rebuild after I blew the engine to discover a 2 inch hole in the top of the petrol tank - right above the exhaust!

Lot's of fun and not too stressing to drive, once you've worked out the lack of head clearance and reversing with the door open as you can see bugger all through the rear window and the side window is too small to get your head through

It's also nice when you catch Ferrari drivers checking out your drive.

Posted 19 June 2007 - 10:34 PM

Posted 19 June 2007 - 10:35 PM

Edited by lvm18, 19 June 2007 - 10:37 PM.

Posted 19 June 2007 - 10:42 PM

Posted 19 June 2007 - 10:44 PM

Posted 19 June 2007 - 10:48 PM

Posted 19 June 2007 - 10:52 PM

Posted 19 June 2007 - 11:28 PM

0 members, 1 guests, 0 anonymous users